Polyester polycondensation catalyst, preparation method and application thereof

A polycondensation catalyst and polyester technology, which are applied to the polyester polycondensation catalyst and the fields of preparation and application thereof, can solve the problems of polluting the environment, yellowing of the product, increase in cost, etc., and achieve the effects of high catalytic efficiency, lower dosage and lower usage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

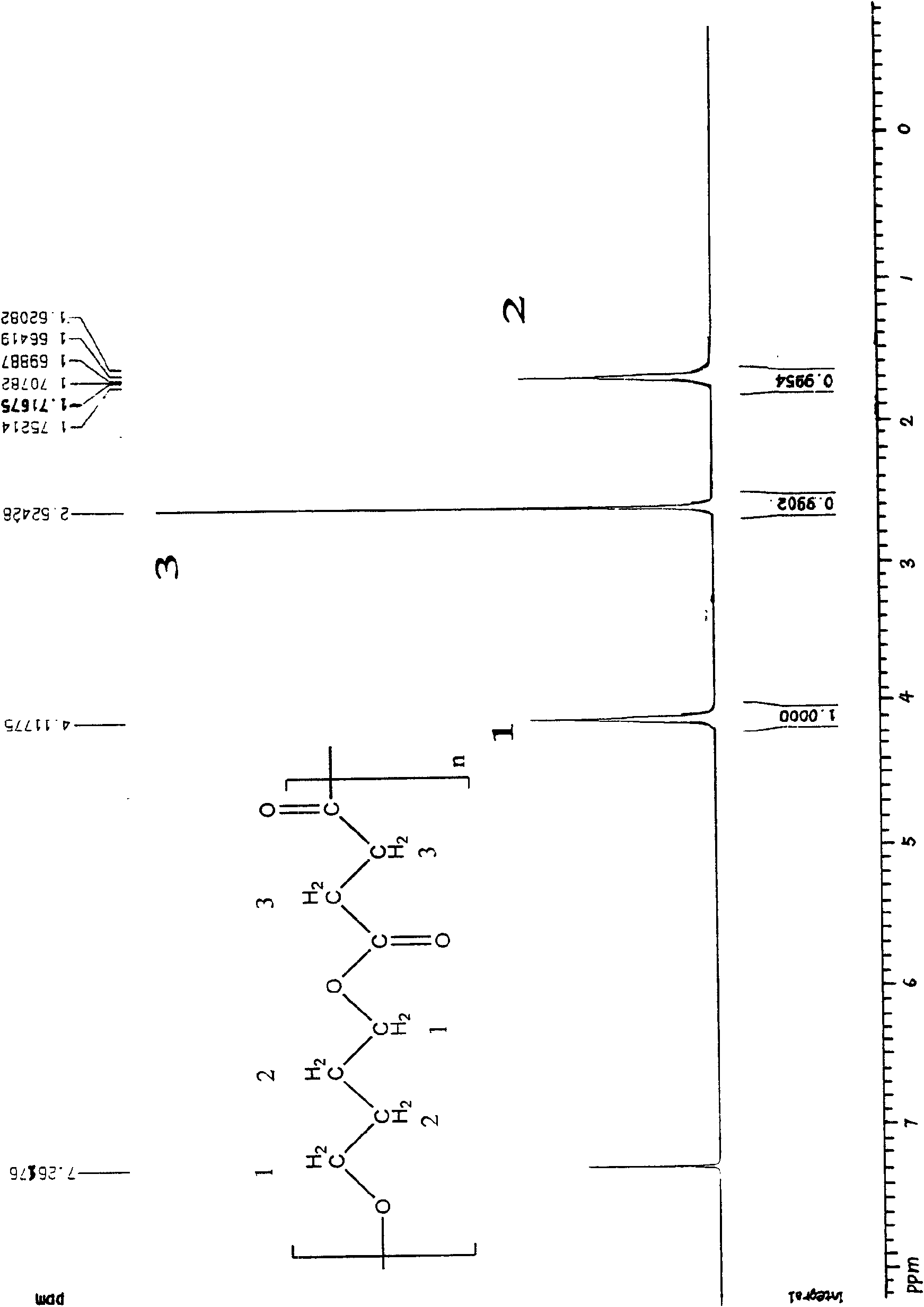

Image

Examples

Embodiment 1

[0023] Embodiment 1, preparation polyester polycondensation catalyst

[0024] Take 5mL concentrated hydrochloric acid, 10mL ethanol, mix with 19.6g tetraethyl orthosilicate (TEOS) at room temperature, stir for 1 hour to obtain the product A SiO 2 Sol.

[0025] Mix 2.5g of titanium tetrachloride with 10mL of concentrated hydrochloric acid at room temperature and stir for 1 hour at room temperature to obtain the product B TiO 2 Sol.

[0026] The product A SiO 2 Sol and product B TiO 2 The sols were mixed and stirred at 50°C for 12 hours to obtain the product CTiO 2 / SiO 2 Sol.

[0027] At room temperature, the product C TiO 2 / SiO 2 The sol was reacted with 3g of 1,2 dimethyl-3-N-hexadecylimidazolium bromide in 30g of water, and after stirring for 8 hours, the supernatant was centrifuged and washed with AgNO 3 Br was not detected - , and vacuum-dried the obtained precipitate at 80° C. to obtain a polyester polycondensation catalyst numbered D, as shown in Table 2.

[...

Embodiment 2

[0029] Embodiment 2, preparation polyester polycondensation catalyst

[0030] Take 5mL concentrated hydrochloric acid, 10mL ethanol, mix with 19.6g tetraethyl orthosilicate (TEOS) at room temperature, stir for 1 hour to obtain the product A SiO 2 Sol.

[0031] Take 2.5g titanium tetrachloride and mix with 10mL concentrated hydrochloric acid, stir at room temperature for 1 hour to obtain the product B TiO 2 Sol.

[0032] The product A SiO 2 Sol and product B TiO 2 The sols were mixed and stirred at 50°C for 12 hours to obtain the product CTiO 2 / SiO 2 Sol.

[0033] At room temperature, the product C TiO 2 / SiO 2 The sol was reacted with 1g of polyvinylpyrrolidone (PVP) in 20g of ethylene glycol, stirred for 24 hours, washed twice with ethylene glycol, and the resulting precipitate was vacuum-dried at 120°C to obtain a polyester polycondensation catalyst numbered G, such as Table 3 shows.

[0034] Using the same preparation method and conditions as above, only 1g of po...

Embodiment 3

[0039] Embodiment 3, preparation polyester polycondensation catalyst

[0040] Take 5mL concentrated hydrochloric acid, 10mL ethanol, mix with 19.6g tetraethyl orthosilicate (TEOS) at room temperature, and stir for 1 hour to obtain the product A SiO 2 Sol.

[0041] Take 2.5g titanium tetrachloride and mix with 10mL concentrated hydrochloric acid, stir at room temperature for 1 hour to obtain the product B TiO 2 Sol.

[0042] The product A SiO 2 Sol and product B TiO 2 The sols were mixed and stirred at 50°C for 12 hours to obtain the product CTiO 2 / SiO 2 Sol.

[0043] At room temperature, the product C TiO 2 / SiO 2 The sol was added to 30 g of water and ethanol with a weight ratio of 1:9 to react with 3 g of hexadecyl triphenylphosphine. After stirring for 8 hours, the supernatant was centrifuged and washed with AgNO 3 Br was not detected - , and vacuum-dried the obtained precipitate at 80° C. to obtain the polyester polycondensation catalyst numbered J provided by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com