Method for preparing ethylene rhodanate-epoxy-POSS hybrid resin

A technology of cyanate resin and epoxy resin, which is applied in the field of organic polymer materials, can solve the problems of heat resistance, mechanical performance and dielectric performance reduction, and achieve the effects of reducing hygroscopicity, improving thermal performance, and increasing impact energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

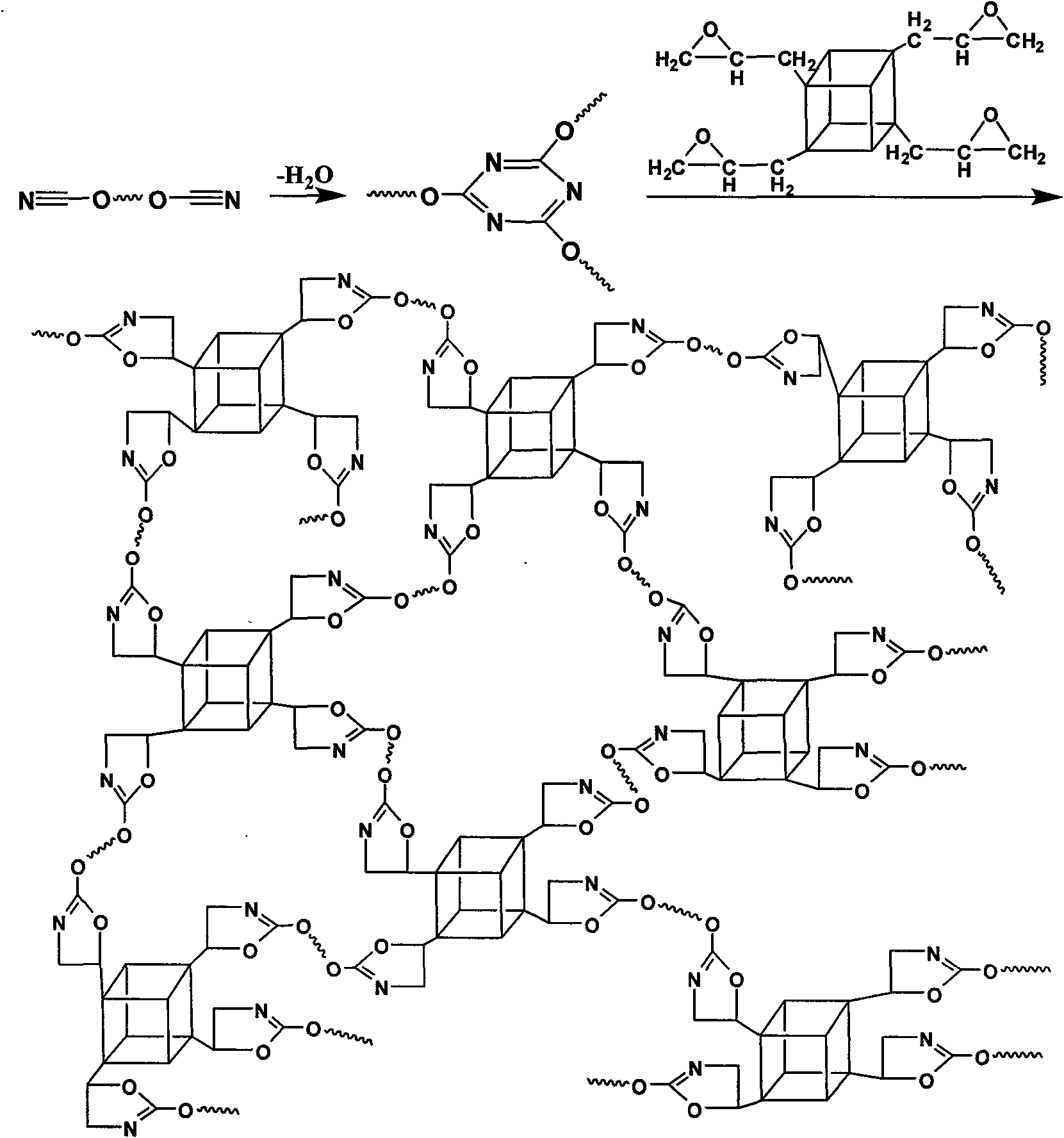

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: Dissolve 400g of bisphenol A type cyanate resin and 600g of brominated bisphenol A type epoxy resin in acetone, make 85wt% mixed solution, add 20g of tetrafunctional epoxy group cage type sesquite For siloxane, add catalyst manganese octoate 0.1g, catalyst 2-methylimidazole 0.2g, stir evenly, pre-react with vacuum at 60°C for 2 hours, then pour into a mold at 80°C, vacuumize and heat to 160°C for 1 hour to cure , After curing for 2 hours at 200°C, the desired cyanate-epoxy resin hybrid material was obtained. Its performance is shown in Table 1.

Embodiment 2

[0017] Embodiment two: 100g bisphenol A type cyanate ester resin and 900g brominated bisphenol A type epoxy resin are dissolved in acetone, are made into 85wt% mixed solution, add 10g tetrafunctional epoxy group cage type sesquite For siloxane, add 0.1g of manganese octoate catalyst and 0.2g of 2-methylimidazole catalyst, stir evenly, pre-react with vacuum at 60°C for 2 hours, then pour into a mold at 80°C, vacuumize and heat to 180°C for 2 hours to cure , After curing for 2 hours at 200°C, the desired cyanate-epoxy resin hybrid material was obtained. Its performance is shown in Table 1.

Embodiment 3

[0018] Embodiment three: 350g bisphenol A type cyanate ester resin, 50g novolak type cyanate ester and 800g brominated bisphenol A type epoxy resin, 100g four-functionalization epoxy resin are dissolved in acetone, are made into 85wt% Mix the solution, add 10g tetrafunctional epoxy group cage silsesquioxane, add catalyst manganese octoate 0.1g, catalyst 2methylimidazole 0.2g, stir evenly, vacuum pre-react at 60°C for 2 hours, then pour into 80 ℃ in the mold, vacuumize and heat to 180 ℃ for 2 hours to cure, 200 ℃ after curing for 2 hours to obtain the desired cyanate ester-epoxy resin hybrid material. Its performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com