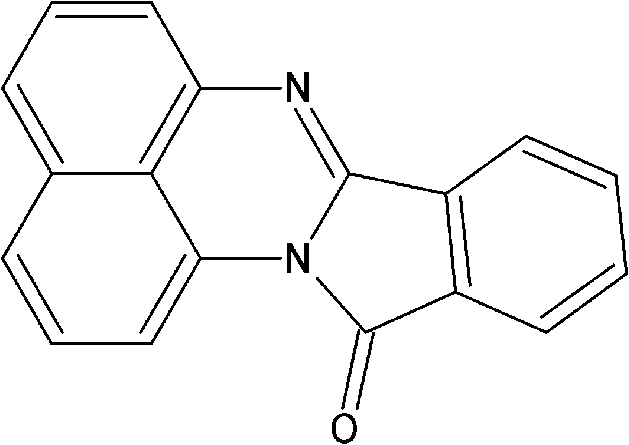

Preparation method for solvent orange 60

A solvent orange and polar organic solvent technology, applied in the field of preparation of solvent orange 60, can solve the problems of difficult product separation, low product vividness, and low production cost, so as to reduce production costs and avoid relatively low product vividness , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

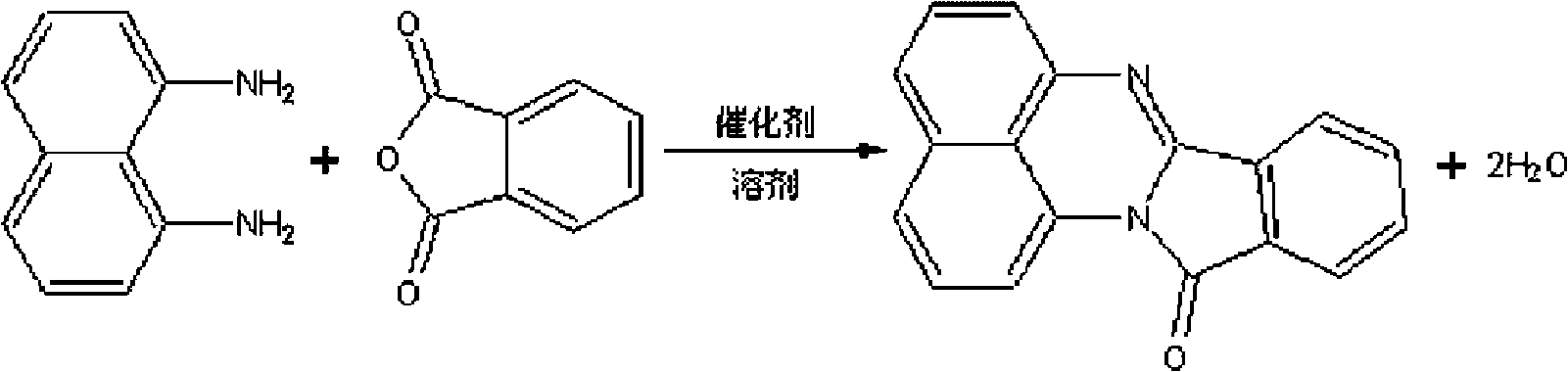

Method used

Image

Examples

Embodiment 1

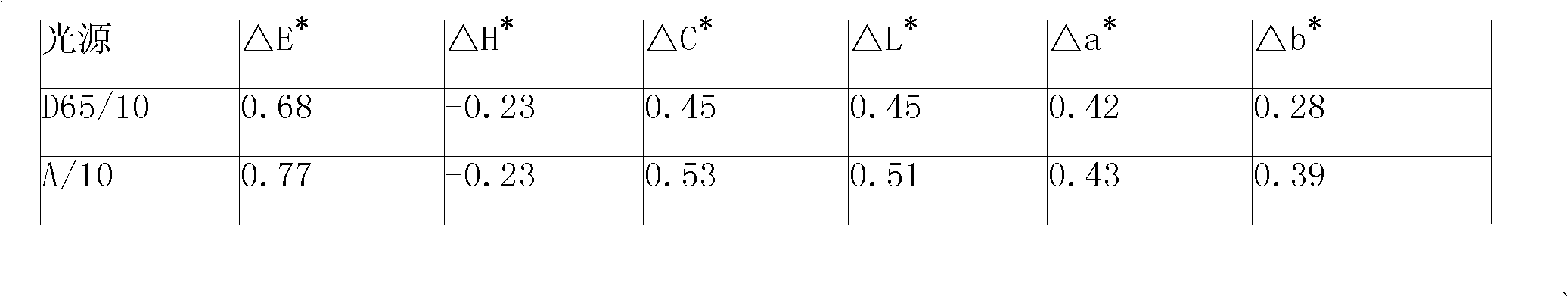

[0017] Add 200g of 3% hydrochloric acid aqueous solution, 30g of alcohol, 10g of phthalic anhydride, 10.7g of 1,8-naphthalene diamine, and 0.3g of fatty alcohol polyoxyethylene ether into a three-necked flask with a stirring and reflux condenser, and start stirring , be warming up to reaction system slight reflux state, filter after reacting for 8 hours, filter cake is washed with clear water until the filtrate is neutral, and dry to obtain product 17.5g (being 95.9% of theoretical yield). The color shade of the product is similar to that of the standard product (see Table 1 for details), and the intensity is 99.0%.

[0018] Table 1

[0019]

[0020]

[0021] (Where: ΔE-color difference, ΔH-hue difference, ΔL-brightness difference, ΔC-chroma difference,

[0022] Δa-the difference in redness and greenness, Δb-the difference in yellowness and blueness, the smaller the ΔE, the closer the color of the product is to the standard product. Generally, if ΔE is less than 3, the...

Embodiment 2

[0024] Add 1000kg 5% hydrochloric acid aqueous solution, 100kg dimethylformamide (DMF), 100kg phthalic anhydride, 107kg 1,8-naphthalene diamine, 5kg Nonylphenol polyoxyethylene ether, start stirring, heat up to the state of slight reflux of the reaction system, filter after 12 hours of reaction, wash the filter cake with water until the filtrate is neutral, and dry to obtain 177kg of the product (96.8% of the theoretical yield) . The product is similar to the standard product (see Table 2 for details), and the strength is 101.0%.

[0025] Table 2

[0026] light source

Embodiment 3

[0028] Add 300kg of 1% hydrochloric acid solution, 60kg of acetic acid, 20kg of phthalic anhydride, 21.4kg of 1,8-naphthalene diamine, and 5kg of nonylphenol polyoxyethylene into a 500L enamel reactor with frame stirring and reflux condenser. Ether, start stirring, heat up to the state of slight reflux of the reaction system, filter after reacting for 8 hours, wash the filter cake with water until the filtrate is neutral, and dry to obtain 35kg of product (95.7% of theoretical yield). The product is similar to the standard product (see Table 3 for details), and the strength is 98.9%.

[0029] table 3

[0030] light source

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com