System for measuring surface bidirectional reflectance distribution

A technology for bidirectional reflection distribution and surface measurement. It is used in measurement devices, optical radiation measurement, photometry, etc. It can solve the problem of inconvenient online measurement and measurement of large target surfaces, inability to measure bidirectional reflection distribution on surfaces, and large repeatability errors. problems, to facilitate online measurement and large target surface measurement, to avoid the interference of retroreflected light, and to achieve the effect of small repeatability error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

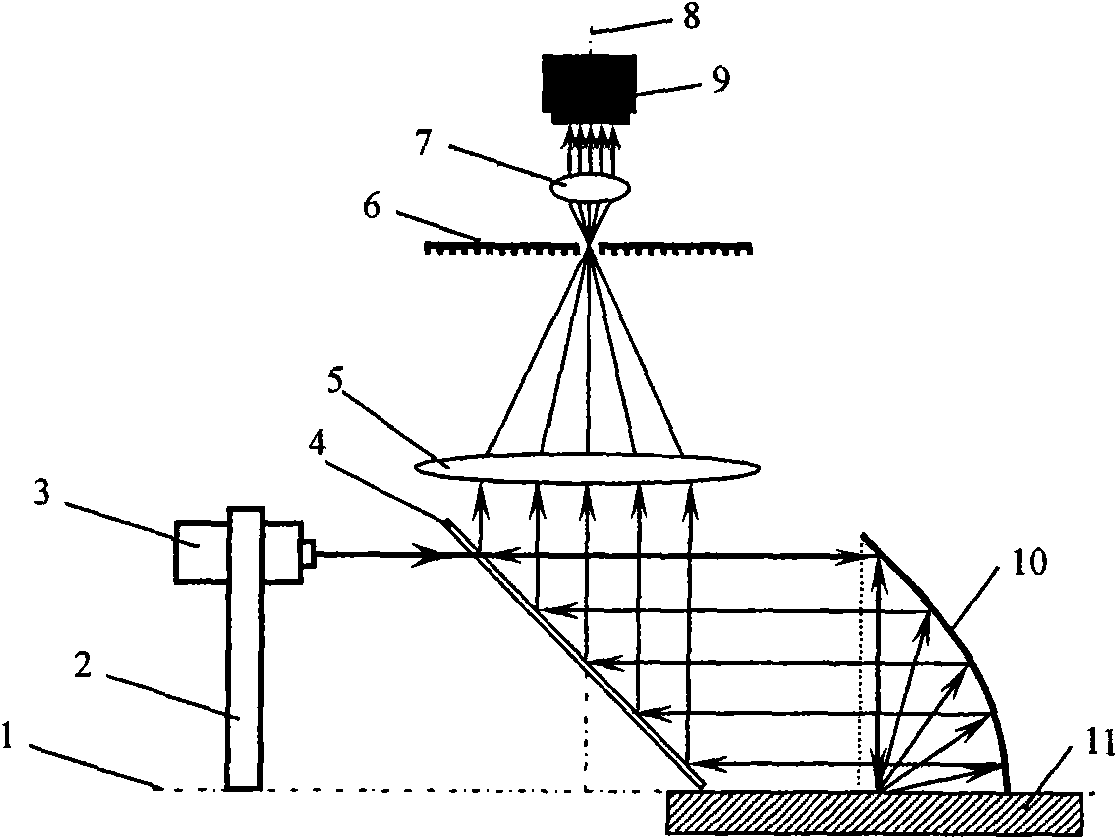

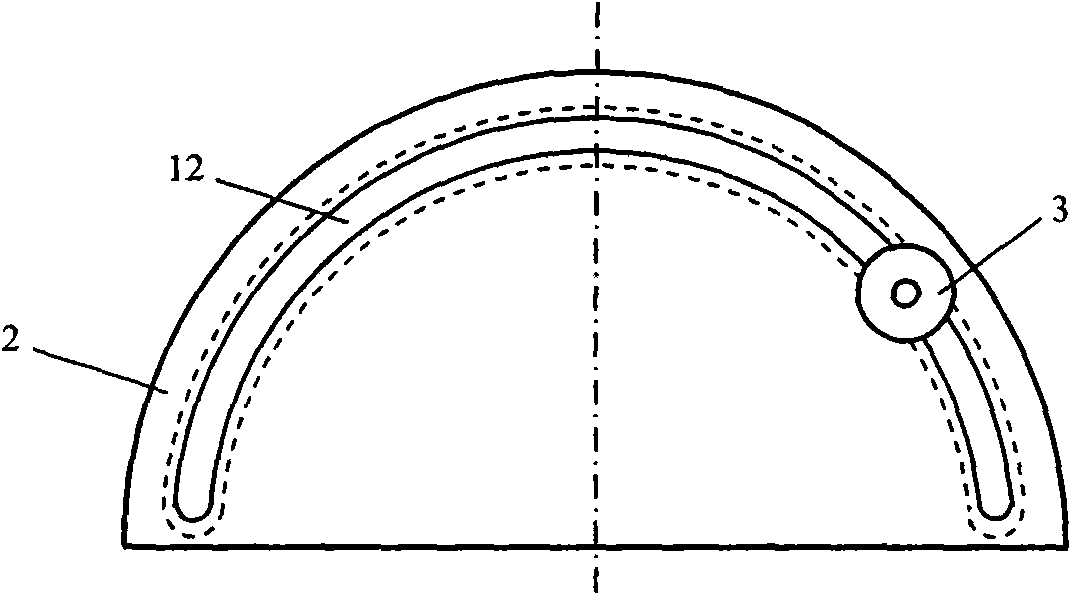

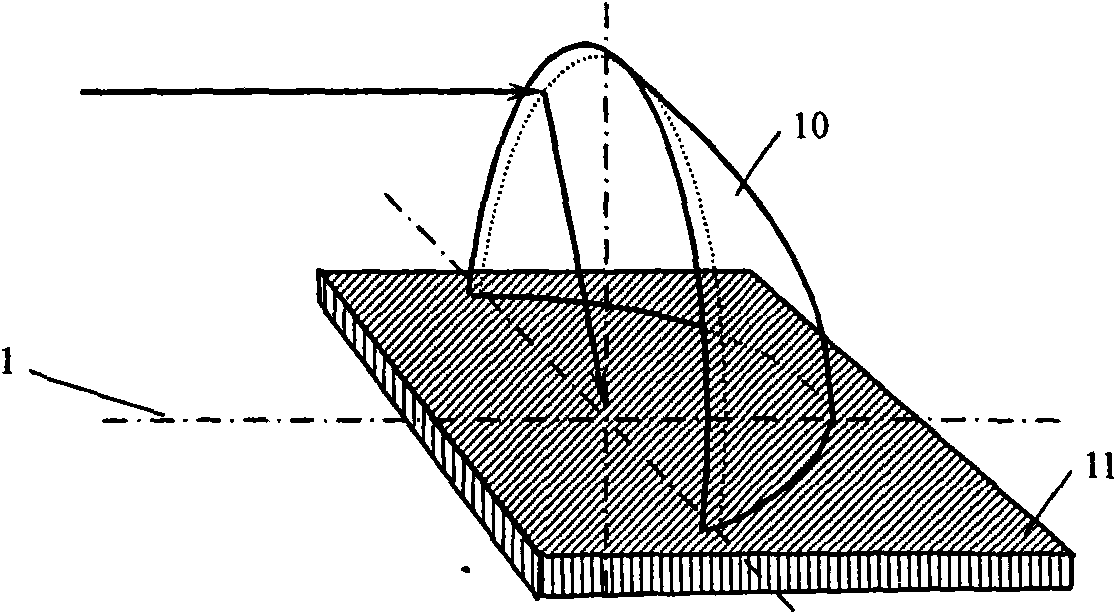

[0031] Such as figure 1 The shown object bidirectional reflection distribution measurement device includes a beam splitter 4, a semi-parabolic mirror 10, a light source system and an imaging system. The beam splitter 4 is fixed between the light source 3 and the parabolic mirror 10, and its normal line forms an angle of 45 degrees with the main axis of the device. The optical axis of the light source 3 is parallel to the main shaft 1 of the device, and the light source 3 is assembled on a semicircular arc slide rail perpendicular to the main shaft 1 of the device, and can rotate around the main shaft 1 of the device. The light source 3 can be a semiconductor laser or other collimated white light source. The light beam emitted by the light source 3 passes through the beam splitter 4, is reflected by the semi-parabolic mirror 10, and converges at its focal point. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com