Method for preparing mulberry cigarette flavor

A technology of spices and mulberries used in cigarettes, which is applied in the field of tobacco in the cigarette industry, can solve the problems of difficult removal of pectin carbohydrates, affect the sensory quality of cigarettes, and increase the stimulation of cigarette smoke, so as to facilitate production transformation, improve cigarette quality, Overcomes residual and irritating effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

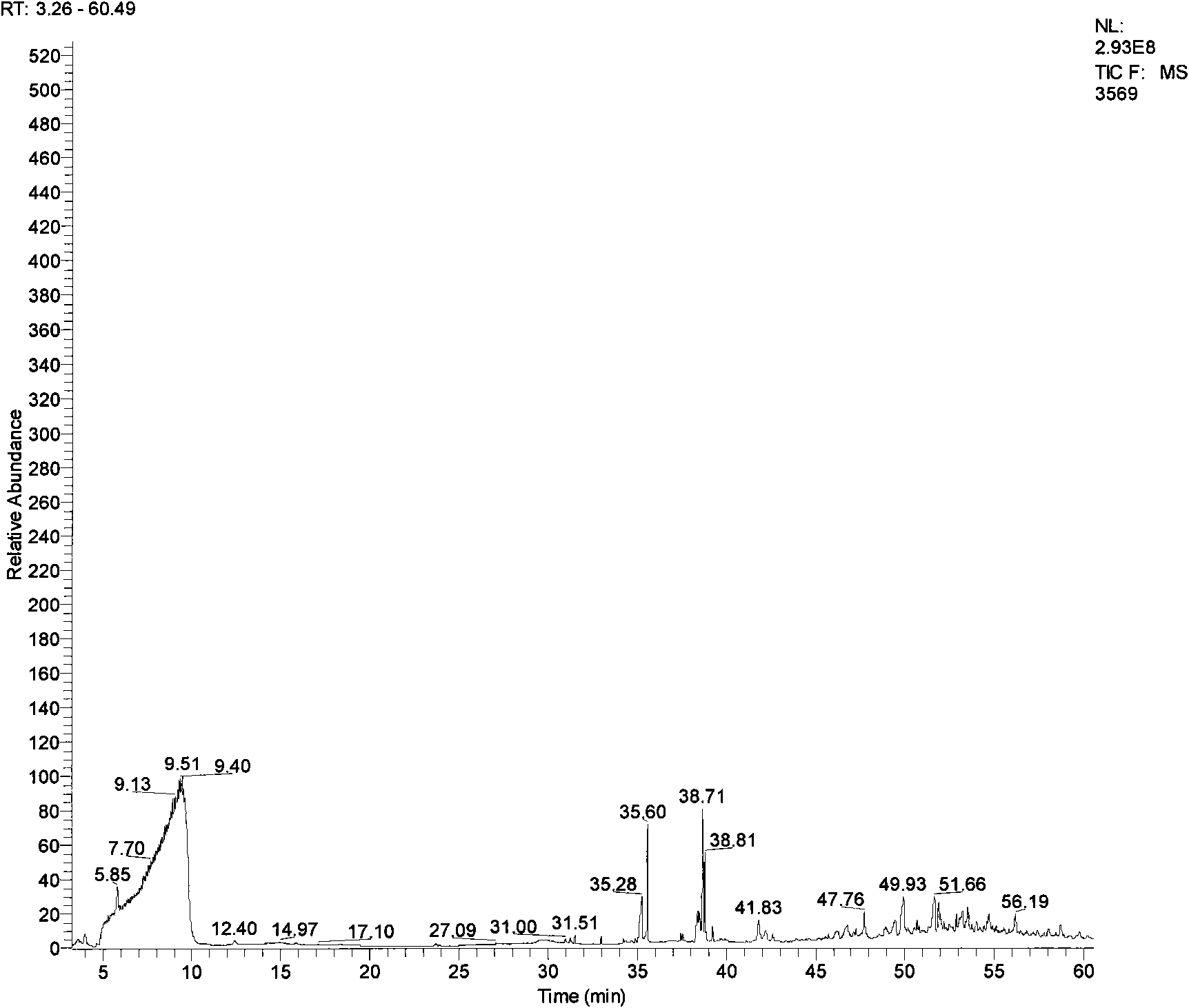

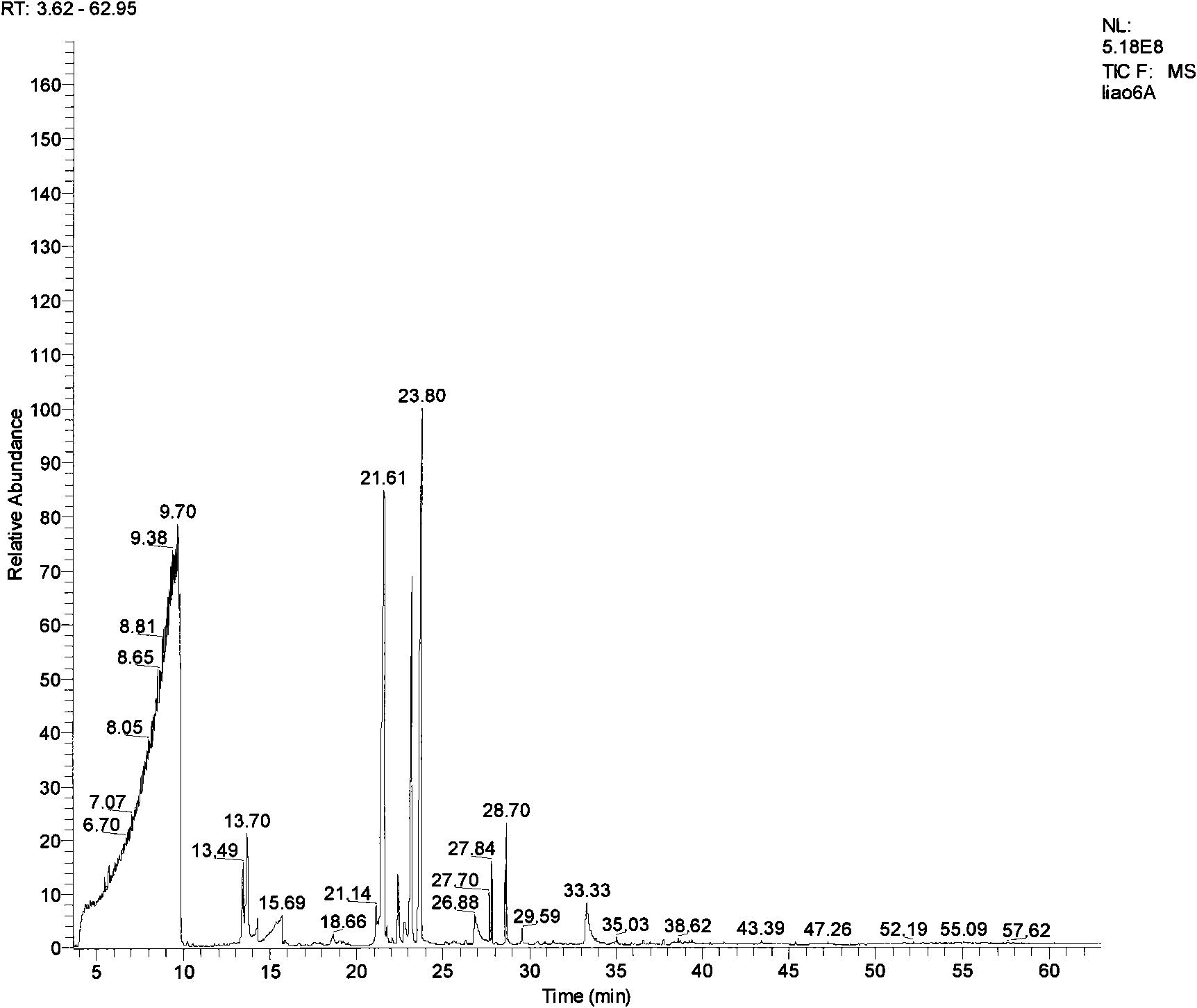

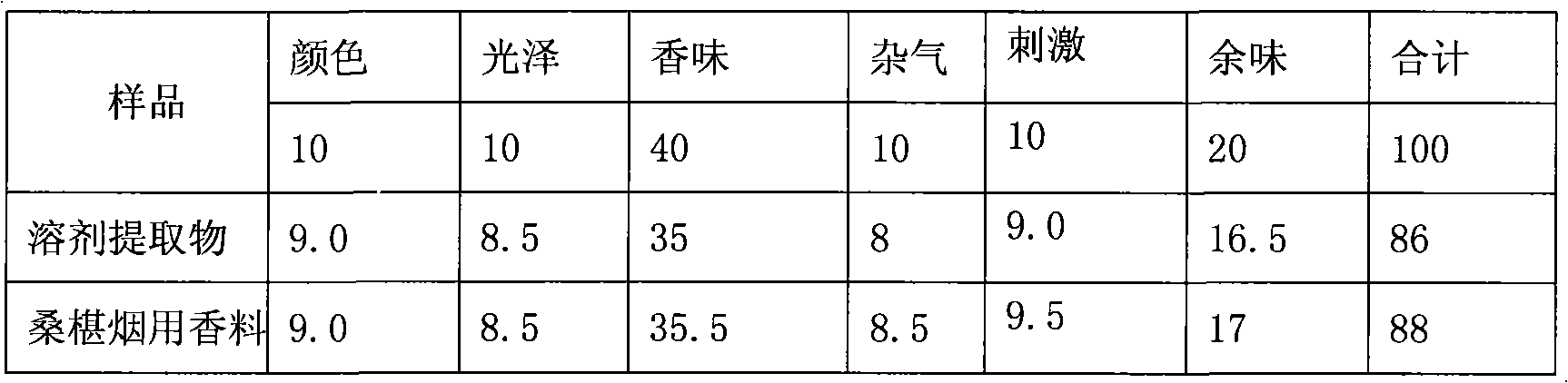

Image

Examples

Embodiment 1

[0036] Embodiment 1. Get the dried fruit of mulberry fruit, rinse thoroughly by flotation, put into oven after constant temperature (60 ℃) dry 8h (moisture control is at about 5%), pulverize and cross 20 mesh sieves. Weigh 100g, add 400g of 75% edible alcohol to soak overnight, distill and extract twice, each time for 4h, the extraction temperature is 85°C. Combine the extracts, let stand, settle naturally for 2 days, add 1 times the amount of petroleum ether for extraction, remove the petroleum ether phase (to basically no residue), concentrate into mulberry water extract, and pass the mulberry water extract through the pretreated macropores Resin D101, rinse with 70% alcohol to obtain mulberry eluate, add 10% propylene glycol in the mulberry eluent, then concentrate it to a bomm degree of 20 to obtain mulberry extract, combine mulberry extract with alcohol solvent After mixing at a ratio of 1:9, the mulberry tobacco flavor is obtained.

Embodiment 2

[0037] Embodiment 2. Get the dried mulberry fruit, rinse it with tap water, put it into an oven at a constant temperature (60° C.) and dry it for 8 hours (moisture is controlled at about 5%), and pulverize through a 20-mesh sieve. Weigh 100g, add 500g of 75% edible alcohol to soak overnight, distill and extract twice, the first time is 4h, the second time is 3h, the extraction temperature is 85°C. Combine the extracts, let stand and settle for 3 days, add 1 times the amount of n-hexane for extraction, remove the n-hexane phase (to basically no residue), concentrate into mulberry water extract, pass the mulberry water extract through the pretreated macroporous resin D140, Rinse with 65% alcohol to obtain the mulberry eluate, add 10% propylene glycol to the mulberry eluate, then concentrate it to a bomm degree of 20 to obtain the mulberry extract, and mix the mulberry extract and the alcohol solvent in a ratio of 1:9 After mixing in the ratio of mulberry tobacco flavoring is obt...

Embodiment 3

[0038] Embodiment 3. Get the dried fruit of mulberry fruit, rinse it with tap water, put it into an oven at a constant temperature (60° C.) and dry it for 8 hours (moisture is controlled at about 5%), and pulverize through a 20 mesh sieve. Weigh 100g, add 400g of 70% edible alcohol to soak overnight, distill and extract twice, each 4h, extraction temperature 85°C. Combine the extracts, let stand for 2 days, add 1 times the amount of pentane for extraction, remove the pentane phase (to basically no residue), concentrate into mulberry water extract, pass the mulberry water extract through the pretreated macroporous resin D101, Rinse with 65% alcohol to obtain the mulberry eluate, add 10% propylene glycol in the mulberry eluent, then concentrate to 20 bomidoness to obtain the mulberry extract, the mulberry extract and the alcohol solvent in a ratio of 1:9 After mixing in proportion, the mulberry tobacco flavor is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com