Method for preparing carbon nanofiber

A technology of carbon nanofibers and direct current electric field, which is applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve the problems of enlarged diameter distribution range, limited applicability and effectiveness, and difficulty in accurately controlling the diameter of CNFs , to achieve the effect of uniform size, strong applicability and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

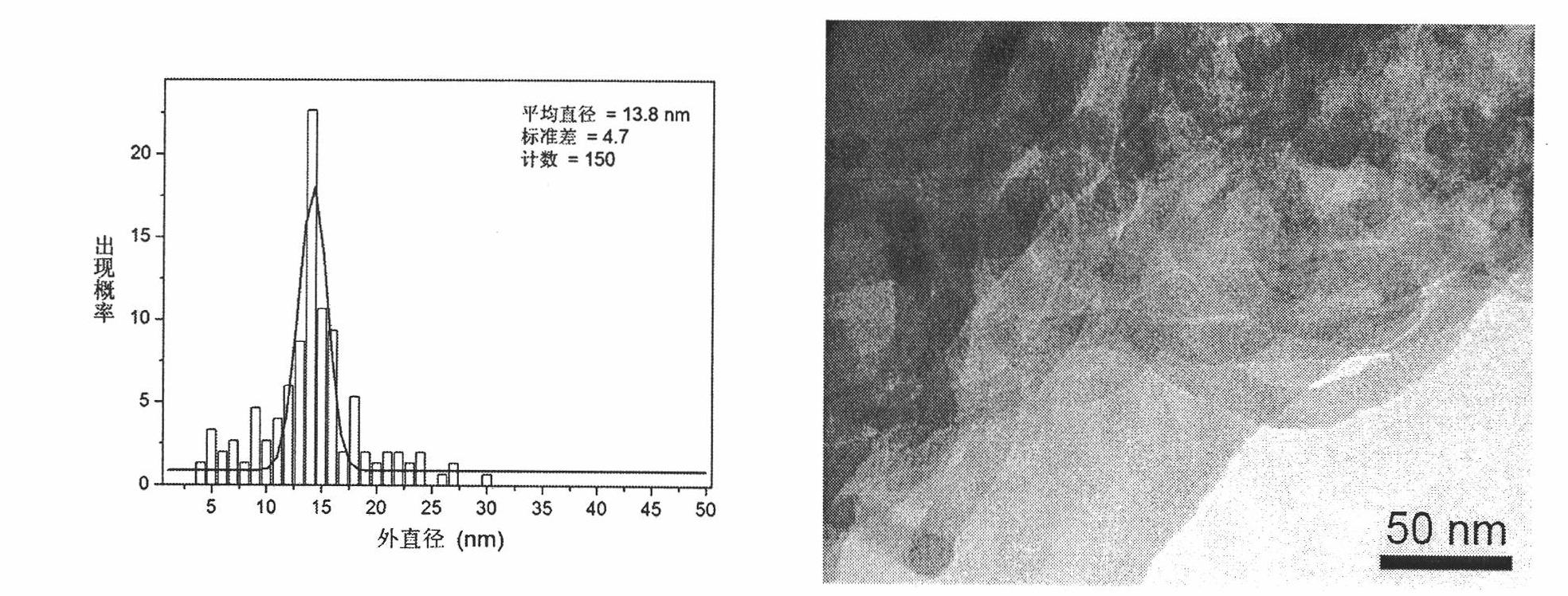

[0025] Example 1: After the deposited substrate numbered M2 was placed in the CVD uniform temperature zone, the furnace chamber was closed, and Ar gas was introduced at a flow rate of 200 sccm, and heated to 600° C. after 40 minutes. At this time, an external electric field is introduced, and the substrate is connected to the negative electrode of the electric field, and the electric field intensity is kept constant at 25000V / m. Inject C at a flow rate of 30 sccm 2 h 2 Gas, the reaction starts and lasts for 3 minutes; after the reaction is completed, turn off the C 2 h 2 Remove the external electric field from the gas valve, and take it out after cooling to room temperature under the protection of Ar gas. The obtained carbon nanofiber transmission electron microscope (TEM) picture and diameter distribution figure are shown in figure 2 ,Such as figure 2 As shown, the average diameter is 13.8nm, and the standard error is 4.7nm.

Embodiment 2

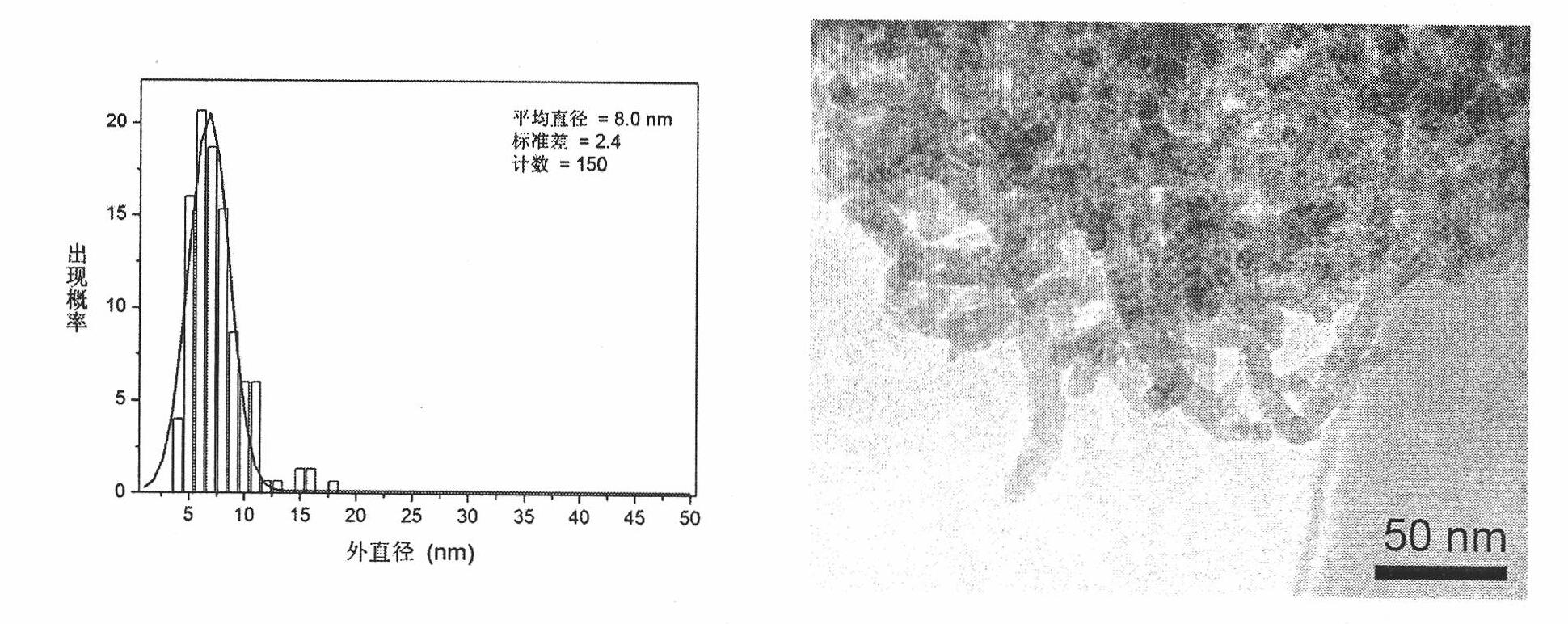

[0026] Example 2: Apply an electric field of 50000 V / m to the deposited substrate numbered M3 (other experimental conditions are the same as in Example 1). The obtained carbon nanofiber transmission electron microscope (TEM) picture and diameter distribution figure are shown in image 3 ,Such as image 3 As shown, the average diameter is 8.0 nm, and the standard error is 2.4 nm.

Embodiment 3

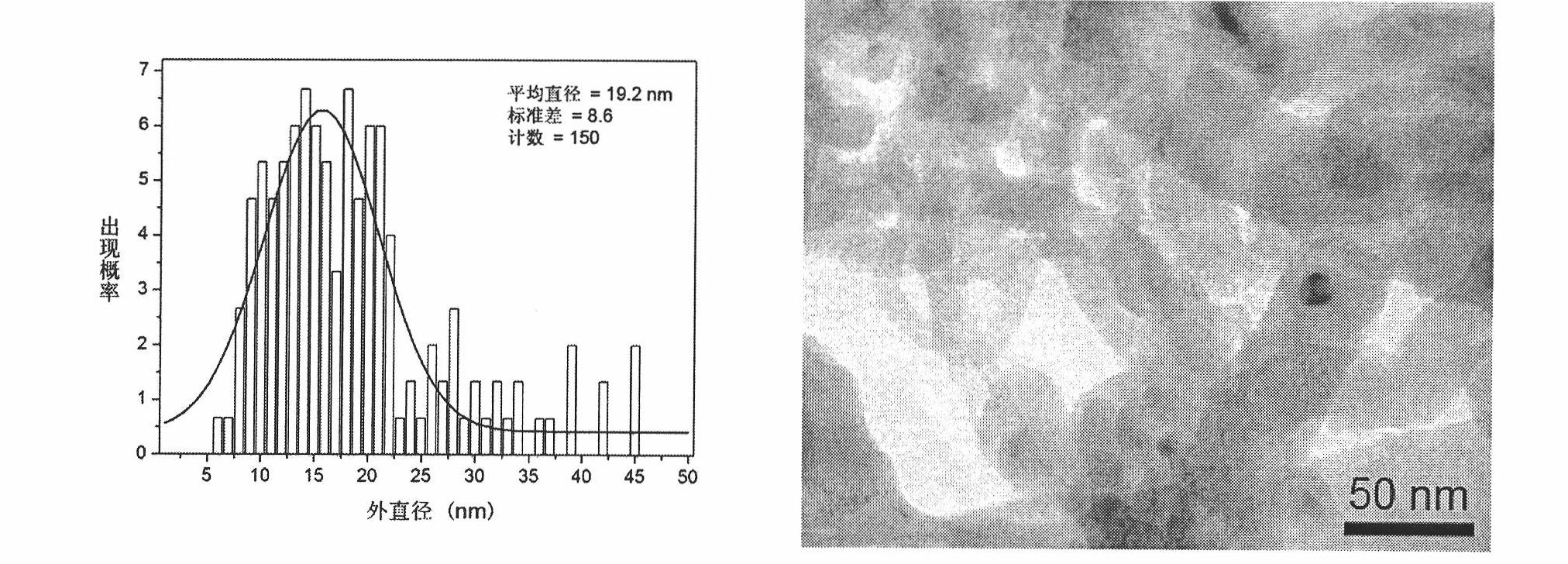

[0027] Example 3: As a comparison, the deposited substrate numbered M1 was also put into CVD, and the experimental conditions were the same as in Example 1, but no electric field was added during the preparation process. The obtained carbon nanofiber transmission electron microscope (TEM) picture and diameter distribution figure are shown in figure 1 ,Such as figure 1 As shown, the average diameter is 19.2 nm, and the standard error is 8.6 nm.

[0028] It can be seen from the above that with the increase of the applied electric field, the average diameter of CNFs and the diameter distribution range are gradually reduced, that is, the purpose of controlling the diameter of CNFs is achieved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com