Method for multilevel vacuum distilling and separating tin-lead alloy

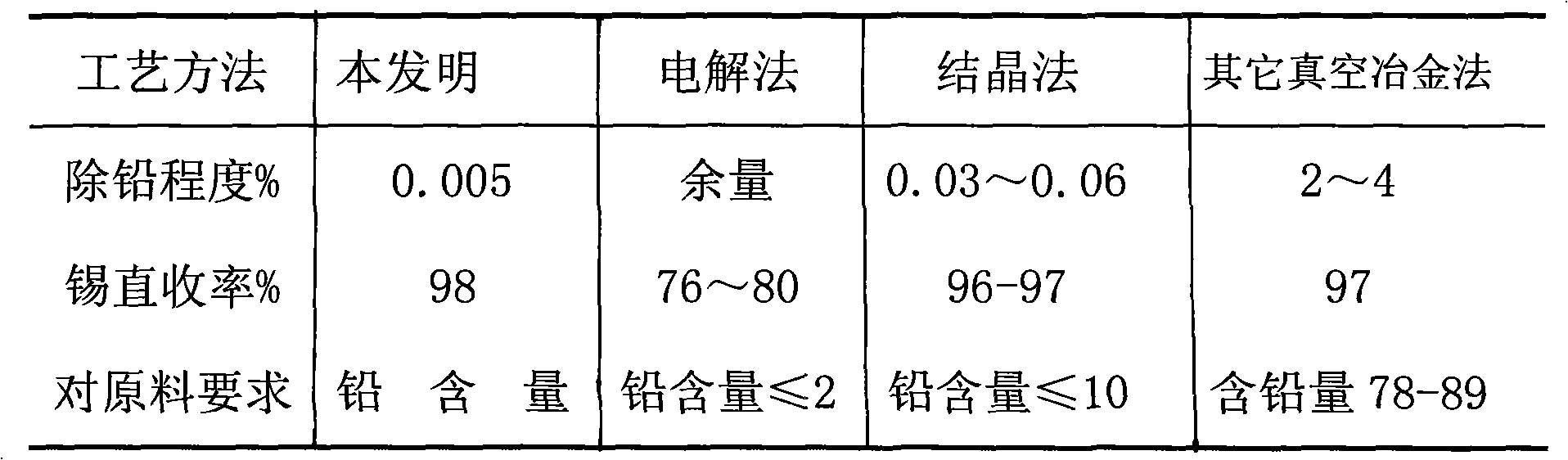

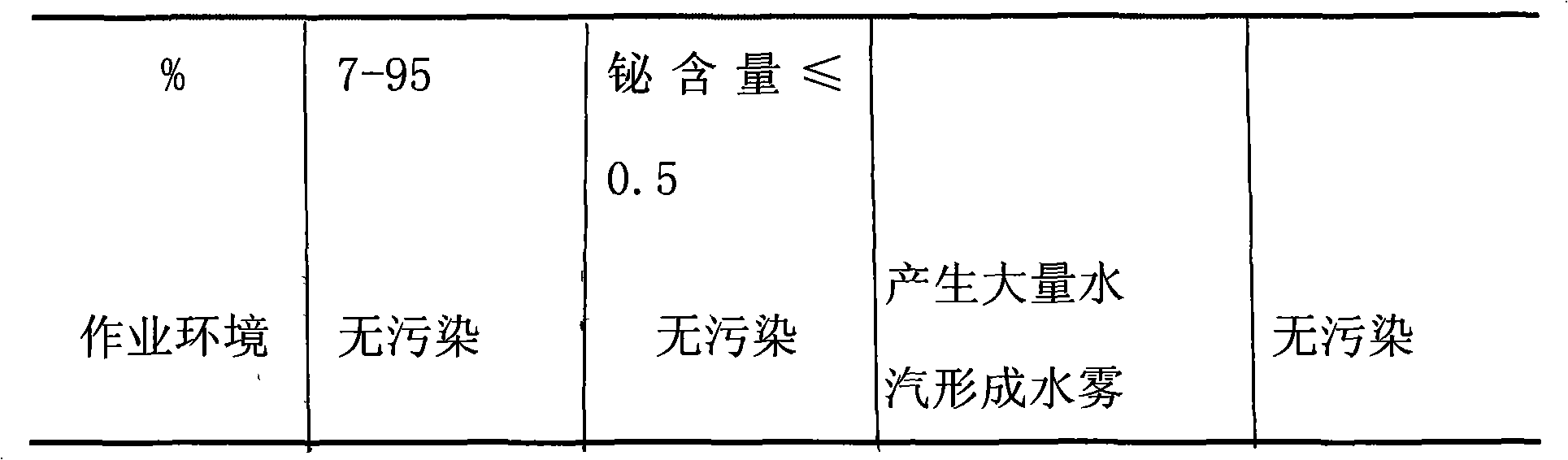

A distillation separation, lead-tin technology, applied in the direction of improving process efficiency, etc., can solve the problems of low metal tin direct recovery rate, low tin direct recovery rate, poor process environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

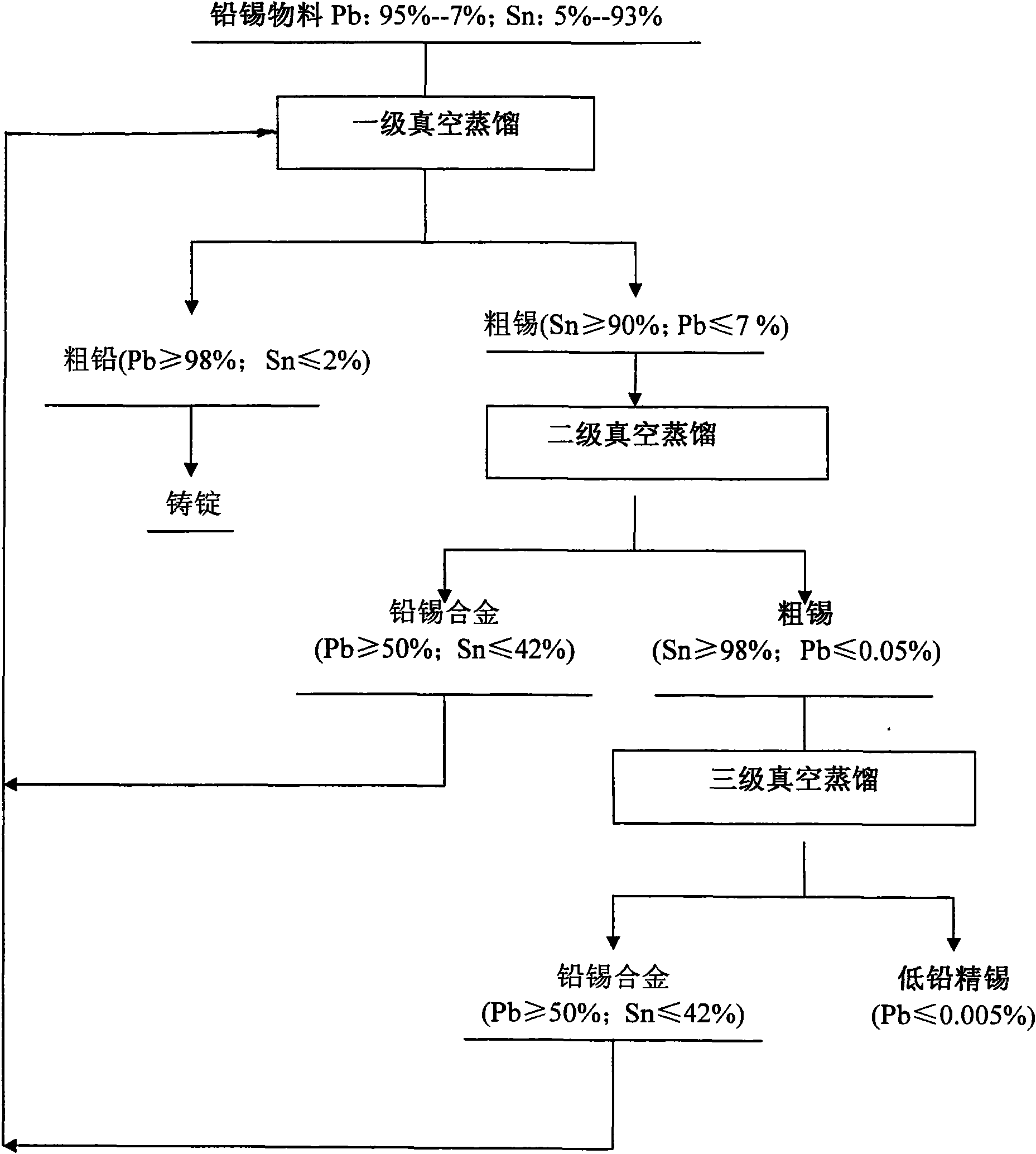

Method used

Image

Examples

Embodiment 1

[0019] Material composition: Sn=85.68 mass%, Pb=12.21 mass%, others 2.11 mass%. The molten material is put into a vacuum furnace for primary distillation, the vacuum degree is controlled at 0.1Pa, the distillation temperature is 900°C, the distillation time is 20 minutes, the processing capacity is 240Kg / h, and a total of 9650Kg is processed. 8455Kg of primary crude tin was produced, accounting for 87.6% of the total processing capacity, with lead content of 0.96% and other 2.32%; crude lead output of 1104Kg, accounting for 11.4% of the total processing capacity, tin content of 1.94%, and other 0.52%; The output scum was 79.8Kg, accounting for 0.83% of the total treatment capacity, and the loss was 11.2Kg, accounting for 0.12% of the total treatment capacity. The average power consumption is 342KWh / h.

[0020] The primary crude tin enters the secondary vacuum distillation, the vacuum degree is controlled at 0.3Pa, the distillation temperature is 1200°C, the distillation time ...

Embodiment 2

[0023] Material composition: Sn=21.84 mass%, Pb=77.99 mass%, others 0.17 mass%. The material is put into a vacuum furnace for primary distillation, and the vacuum degree is controlled to 0.1Pa; the distillation temperature is 1050°C, the distillation time is 20 minutes, and the processing capacity is 260Kg / h, with a total of 9500Kg processed. The primary crude tin output is 2185Kg; the primary crude tin enters the secondary vacuum distillation, the vacuum degree is controlled at 0.1Pa, the distillation temperature is 1150°C, the distillation time is 15 minutes, the processing capacity is 150Kg / h, and a total of 8455Kg is processed. The output of the secondary crude tin is 8290Kg; the secondary crude tin enters the tertiary vacuum distillation, and the vacuum degree is controlled to 0.5Pa; the distillation temperature is 1250°C, the distillation time is 10 minutes, the processing capacity is 150Kg / h, and the total processing is 8290Kg. The output of refined tin is 8260Kg, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com