Modification method for preparing highly-hydrophilic real silk fiber spunlace non-woven material

A non-woven material, hydrophilic modification technology, used in fiber processing, animal fibers, textiles and papermaking, etc., can solve the problems that silk fibers are not easily entangled with each other, affect the quality of the spunlace process, and affect the quality of products. Soft texture, increased moisture content, and increased moisture regain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

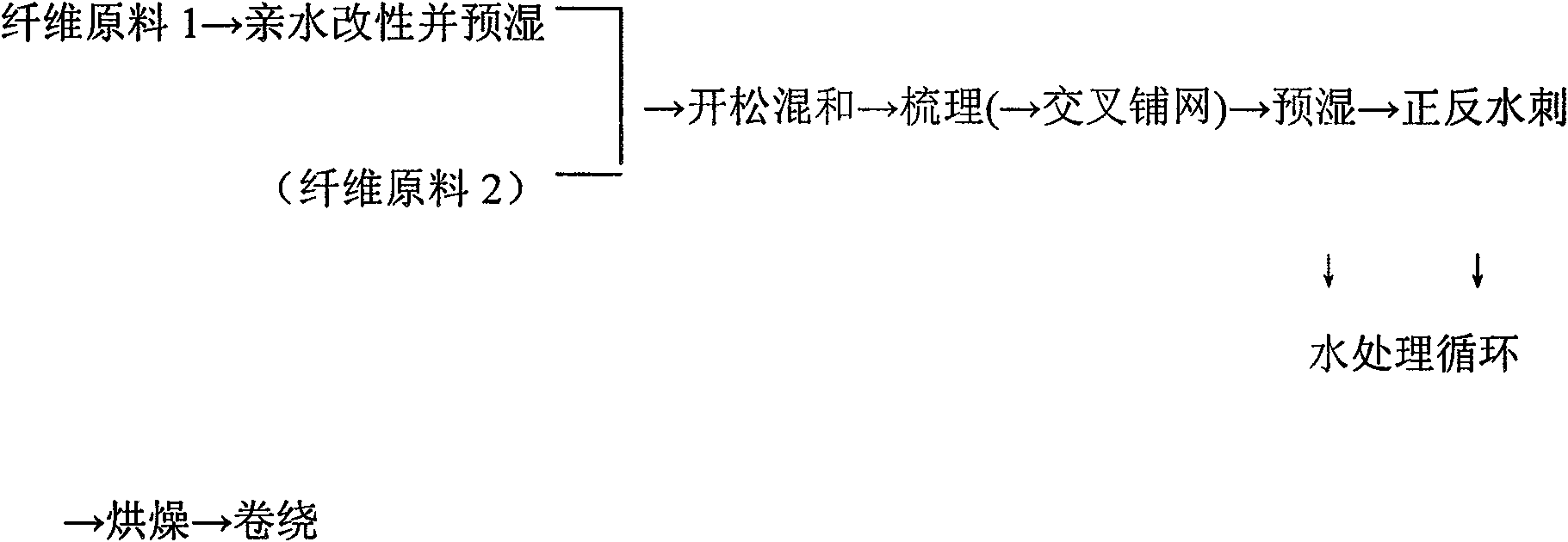

Method used

Image

Examples

example 1

[0020] (1) Raw materials: No. II cotton sheet purchased from the market.

[0021] (2) Hydrophilic modification:

[0022] Reagent formula: DELION Nw-269 and DELION Nw-344 hydrophilic reagents from Japan Take Corporation, the mass ratio is 20:80; the water used for preparing the solution is distilled water, ph=7; the reagent mixing temperature is 75°C; the solution concentration: 0.3%;

[0023] Process conditions: soaking time 8 minutes, bath ratio 1:20, dehydration time 5 minutes, drying temperature 80 ° C, drying time 3 hours; (3) cutting, pre-wetting: mechanical cutting length is 38 mm; the quality of spraying on silk fibers is dry Tap water with a weight of 17%, even if its moisture regain reaches 17%, let it stand for 24 hours;

[0024] (4) Carding: carding machine line speed 50m / min

[0025] (5) Spunlace pressure: the first 40bar; the second 50bar; the third 60bar; the fourth 70bar;

[0026] (6) Drying temperature: the temperature of the first group of dryers is 100°C, ...

Embodiment 1

[0028] The performance test of the highly hydrophilic silk spunlace nonwoven material of embodiment 1 is as follows:

[0029] Gram weight: 30g / m 2

[0030] Thickness: 0.52mm

[0031] Tensile breaking strength: longitudinal 77.3N / 5cm, transverse 18.1N / 5cm

[0032] Longitudinal / transverse fracture strength ratio: 4.3

[0033] Water Absorption: 923.7%

[0034] Liquid penetration time: 17s

[0035] Liquid return moisture content: 2.35g

[0036] Liquid sliding volume: 1.94g

example 2

[0038] (1) Raw materials: No. II cotton sheet purchased from the market, 1.56dtex×38mm polyester staple fiber for spunlace;

[0039] (2) Hydrophilic modification:

[0040] Reagent formula: DELION Nw-269 and DELION Nw-344 hydrophilic reagents from Take Corporation, Japan, with a mass ratio of 10:90; the water used to prepare the solution is distilled water, ph=7; the mixing temperature of the reagents is 75°C; the concentration of the solution: 0.2%;

[0041] Process conditions: soaking time 8 minutes, bath ratio 1:20, dehydration time 5 minutes, drying temperature 80 ° C, drying time 3 hours; (3) cutting, pre-wetting: mechanical cutting length is 38 mm; the quality of spraying on silk fibers is dry Tap water with a weight of 17%, even if its moisture regain reaches 17%, let it stand for 24 hours;

[0042] (4) Mixing: Put the modified silk and polyester into the opener according to the mass ratio of 50:50, and then open and mix through the cleaning and carding unit;

[0043] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Tensile breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com