Method for preparing iodobenzene diacetate

A technology of iodobenzene diacetate and iodobenzene, which is applied in the field of preparation of oxidant iodobenzene diacetate, which can solve problems affecting the environment, pollution, hidden dangers, etc., and achieve the effects of simple operation, reasonable process and safe production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

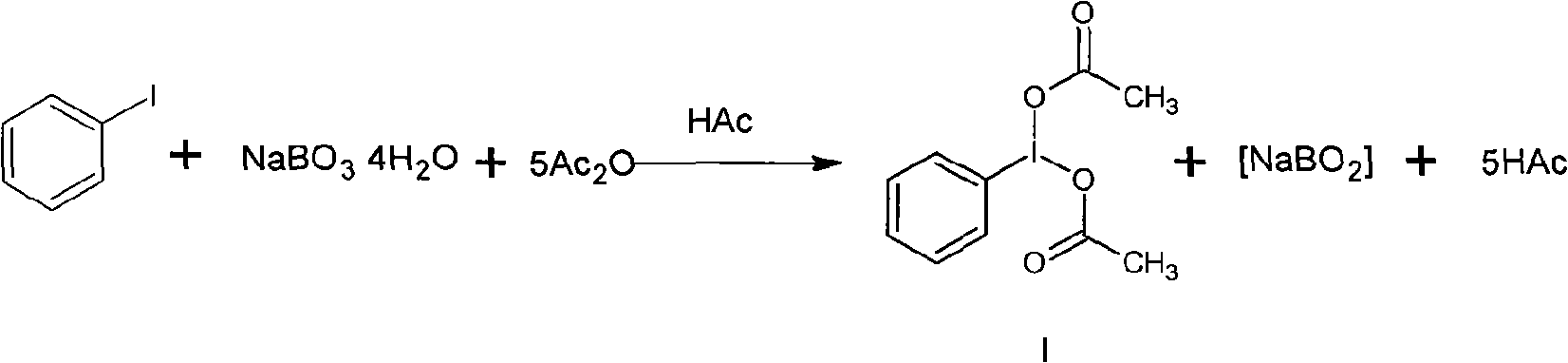

[0021] A method for preparing iodobenzene diacetate, the method may further comprise the steps:

[0022] Add 40.8 grams (0.2mol) of iodobenzene to 250 milliliters of glacial acetic acid and 250 milliliters of acetic anhydride, heat to 35-40 degrees, then add 184.8 grams (1.2mol) of sodium perborate tetrahydrate in batches within 30 minutes, and the reaction temperature is maintained at 40-45 degrees, then keep warm at 40-45 degrees and react for 12 hours, then cool to room temperature, add 1500 ml of ice water, precipitate iodobenzene diacetate crude product, recrystallize with glacial acetic acid / petroleum ether to obtain 46 grams, yield 71.4% . Melting point: 158-160°C, content 100.7%.

Embodiment 2

[0024] A method for preparing iodobenzene diacetate on a large scale, the method may further comprise the steps:

[0025] Add 600 grams (2.94mol) of iodobenzene to 4 liters of glacial acetic acid and 2 liters of acetic anhydride, heat to 35-40 degrees, then add 1400 grams (9.1mol) of sodium perborate tetrahydrate in batches within 40-60 minutes, the reaction temperature Maintain at 40-45 degrees, then keep warm at 40-45 degrees and react for 6 hours, then cool to room temperature, add 12 liters of ice water, precipitate iodobenzene diacetate crude product, recrystallize with glacial acetic acid / petroleum ether to obtain 635 grams, yield 66.8%. Melting point: 160-164°C, content 99.2%.

Embodiment 3

[0027] A kind of preparation method of iodobenzene diacetate, this method takes sodium perborate tetrahydrate as raw material, is made into acylation reagent with glacial acetic acid / acetic anhydride mixed solution, the volume of glacial acetic acid and acetic anhydride in glacial acetic acid / acetic anhydride mixed solution Ratio is 2: 1, sodium perborate tetrahydrate is fed in batches within 15 minutes, and acylation reaction occurs with iodobenzene, wherein the mol ratio of sodium perborate tetrahydrate and iodobenzene is 3: 1, and the reaction temperature is 30°C, The reaction time was 4 hours. After the reaction was completed, ice water with 16 times the volume of iodobenzene was added to obtain the crude product of iodobenzene diacetate, which was then recrystallized by glacial acetic acid / petroleum ether to obtain iodobenzene diacetate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com