Reactive acid yellow dye for nylon and preparation method thereof

A acid yellow and reactive technology, applied in reactive dyes, dyeing methods, azo dyes, etc., can solve the problems of dye shedding, poor fastness, fading and discoloration, etc., and achieve good fastness performance, good wet fastness, The effect of strong binding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

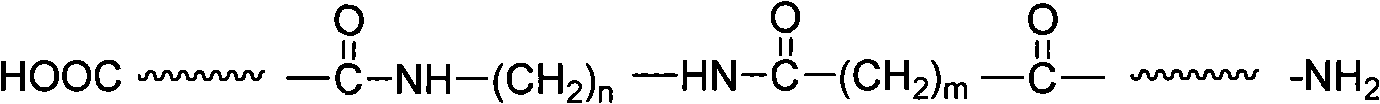

Method used

Image

Examples

Embodiment Construction

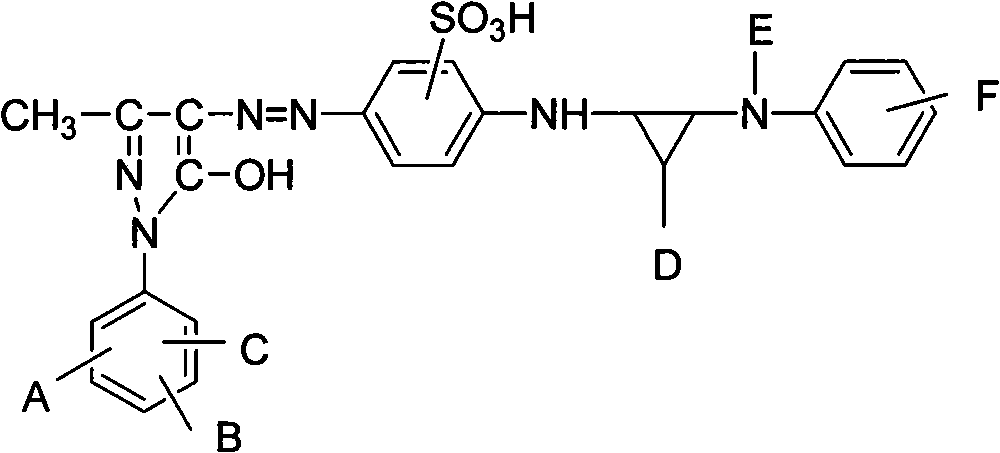

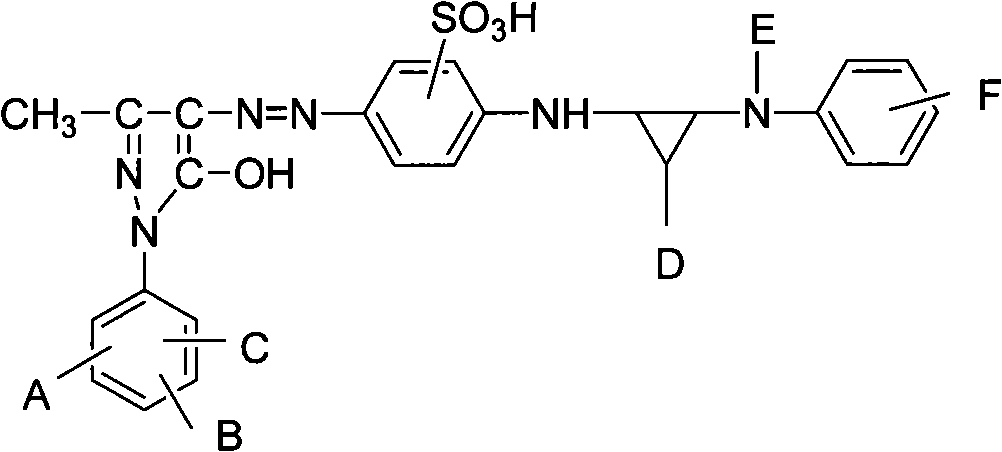

[0069] Reactive acid yellow dye, its molecular structure is as follows:

[0070]

[0071] in:

[0072] A=Cl

[0073] B=Cl

[0074] C=SO 3 h

[0075] D=Cl

[0076] E=H

[0077] F=SO 2 CH 2 CH 2 OSO 3 H, called a; or F=SO 2 CH=CH 2 , called b;

[0078] The acid yellow dye is a mixture when F is a and b; a:b=1:0.6-0.05; preparation method:

[0079] (1) condensation

[0080] Add water and an appropriate amount of ice into the reaction kettle, add cyanuric chloride, stir and beat at 0-5°C, then add m-phenylenediamine sulfonic acid, and react at 0-3°C for 1-3 hours; cyanuric chloride, The ratio of the amount of m-phenylenediamine sulfonic acid is 1:1 (mol / mol).

[0081] (2), diazotization

[0082] Use alkali solution to adjust pH=6.5~7.0, immediately add hydrochloric acid (m-phenylenediaminesulfonic acid: hydrochloric acid: sodium nitrite=1:2.5:1.01 (mol / mol), add ice, slowly add sodium nitrite solution, in 8~10℃, pH=1~2, under the conditions of excessive sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com