Method for classifying partial glyceride with low freezing point

A technology with low freezing point and grading method, which is applied in the direction of fat oil/fat separation and fat production. It can solve the problems of harsh equipment and fractionation conditions, unfavorable large-scale industrial application, and high reagent cost. It achieves low freezing point, small investment, and The effect of low raw material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

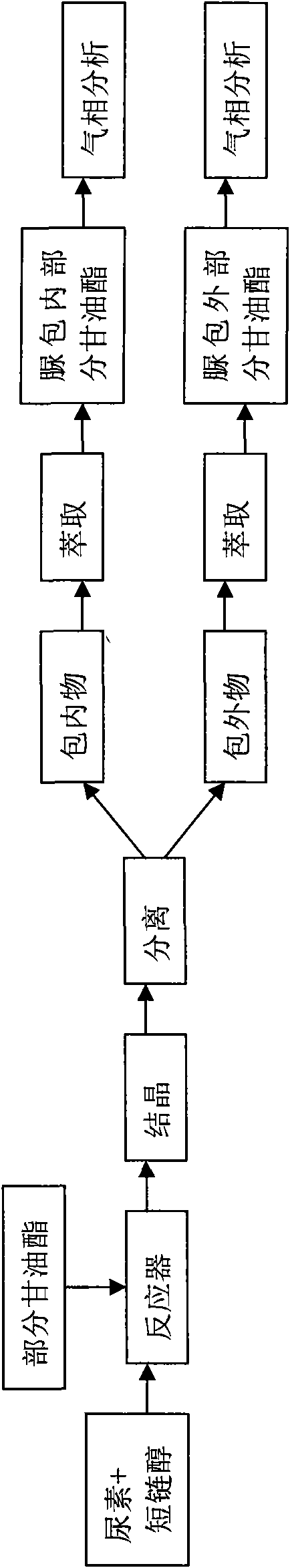

Method used

Image

Examples

Embodiment 1

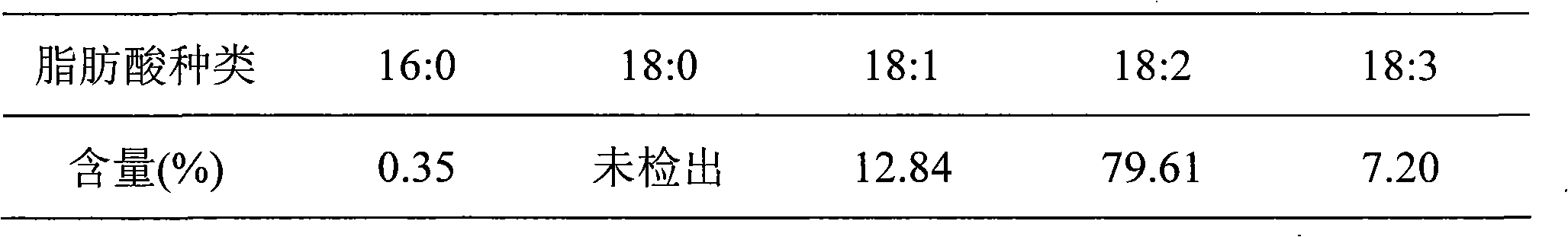

[0021] Weigh 20 g of urea into an Erlenmeyer flask, add 40 mL of 95% ethanol, and heat it under reflux in a constant temperature water bath at 70°C until the urea is completely dissolved. Weigh 10g of monoglyceride and slowly add it to the solution, heat it under reflux at 70℃ for 15min, then put it in a water bath at 25℃ to cool and crystallize for 0.5h, and separate the solid phase and the liquid phase by suction filtration. The monoglycerides were extracted with petroleum ether (solid phase or liquid phase: organic solvent=1:1.5 (m / v); extraction twice), and then the petroleum ether was removed by rotary evaporation (temperature 50°C, vacuum degree 0.096MPa), The separated monoglycerides were analyzed by gas chromatography, and the liquid product analysis results are shown in Table 1. The content of saturated fatty acids in the package is 0.35%, and the content of unsaturated fatty acids is 99.65%. The DSC analysis shows that the liquid monoglyceride has an obvious exothermic p...

Embodiment 2

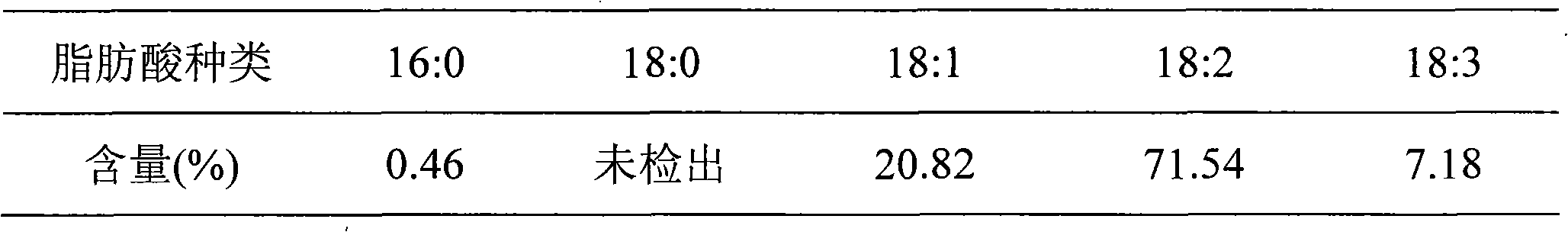

[0025] Weigh 30 g of urea into an Erlenmeyer flask, add 120 mL of methanol, and reflux and heat in a constant temperature water bath at 70° C. until all the urea is dissolved. Weigh 10g of monoglycerides and slowly add them to the solution, heat under reflux at 70°C for 20 minutes, and then place it in a water bath at 20°C to cool and crystallize for 1 hour. The solid phase and the liquid phase are separated by suction filtration, and the glycerin in the solid and liquid phases is separated One ester was extracted with n-hexane (solid phase or liquid phase: organic solvent=1:1.5 (m / v), twice extraction), and then the n-hexane was removed by rotary evaporation (temperature 50℃, vacuum degree 0.096MPa), right The separated monoglycerides were analyzed by gas chromatography. The analysis results of liquid monoglycerides are shown in Table 2. The content of saturated fatty acids in the package is 0.46% and the content of unsaturated fatty acids is 99.54%. It can pass the 0℃ freezing t...

Embodiment 3

[0029]Weigh 40 g of urea into an Erlenmeyer flask, add 80 mL of mixed alcohol (methanol:ethanol=1:1, v / v), and heat it under reflux in a constant temperature water bath at 70°C until all the urea is dissolved. Weigh 10g of monoglyceride and slowly add it to the solution, heat it under reflux at 70°C for 18min, then place it in a water bath at 30°C to cool and crystallize for 2h, separate the solid phase and the liquid phase by suction filtration, and separate the glycerin in the solid phase and the liquid phase. One ester was extracted with ether (solid phase or liquid phase: organic solvent=1:1.5 (m / v); extraction twice), and then the ether was removed by rotary evaporation (temperature 50℃, vacuum degree 0.096MPa), and then separated The monoglycerides were analyzed by gas chromatography. The analysis results of liquid monoglycerides are shown in Table 3. The content of saturated fatty acids in the package is 0.57%, and the content of unsaturated fatty acids is 99.43%. It can pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com