Hydrogen selective catalytic reduction device and control method thereof

A control method and selective technology, applied in the direction of electronic control of exhaust treatment devices, exhaust devices, noise reduction devices, etc., can solve the problems of three-way catalytic converter failure, application difficulties, heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

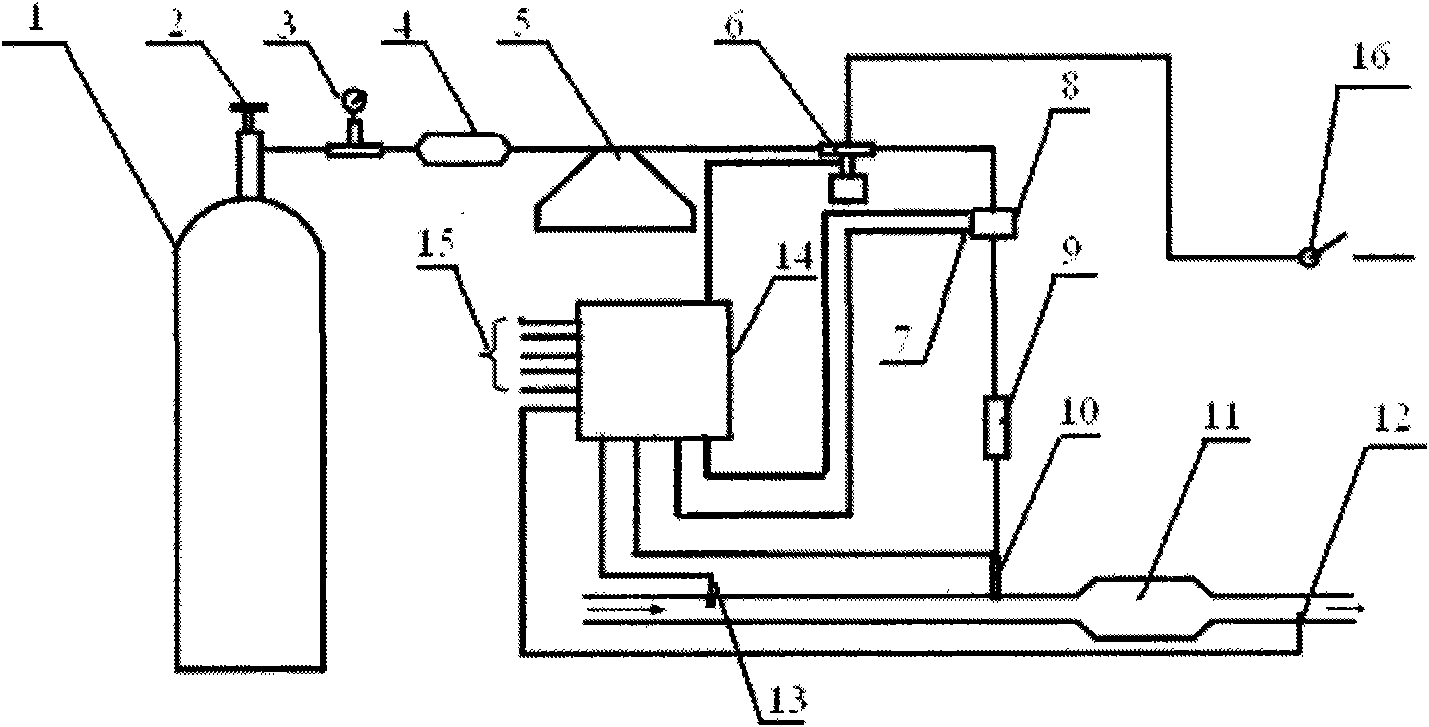

[0009] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0010] a H 2 -SCR system consists of high-pressure gas cylinder 1, manual valve 2, pressure gauge 3, gas filter 4, hydrogen flow meter 5, high-pressure solenoid valve 6, gas temperature and pressure sensor 7, pressure reducer 8, and tempering controller 9. A hydrogen gas injection valve 10, a post-catalysis processor 11, a post-catalysis NOx concentration sensor 12, a pre-catalysis NOx concentration sensor 13 and an electronic control unit 14. Hydrogen is stored in the high-pressure hydrogen cylinder 1 at a pressure of 20 MPa. During the calibration test, firstly open the manual valve 2 to supply air to the system, open the key door 16 to start the engine, and simultaneously open the high-pressure solenoid valve 6 to supply air to the H 2 - The electronic control unit 14 of the SCR system supplies power, and the electronic control unit 14 determines the working s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com