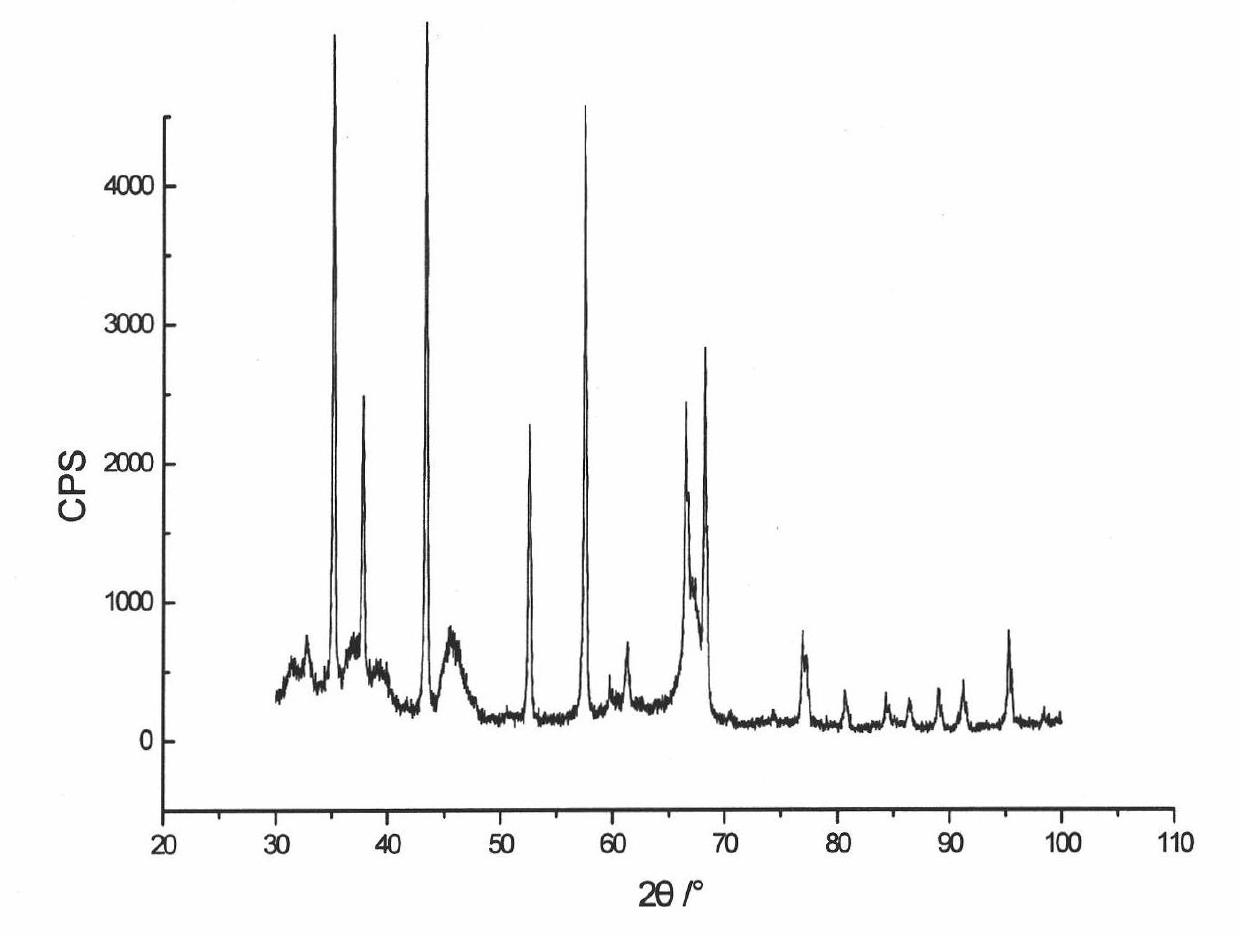

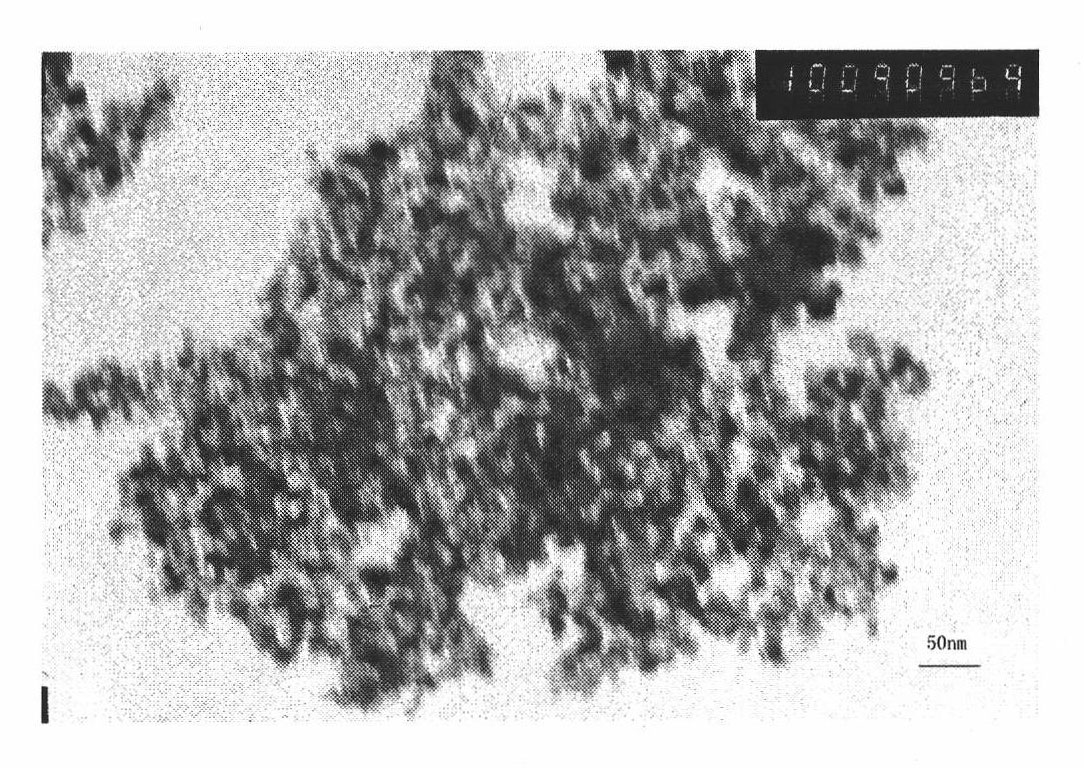

Preparation method of nanometer zinc powder based on reducing atmosphere produced by methanol catalytic pyrolysis

A technology of catalytic cracking and nano-zinc powder, applied in the field of preparation of nano-zinc powder, can solve the problems of difficulty in industrialized production, easy deformation of crystal grains, uneven control and distribution, etc., and achieves no three-waste pollution, small particle size, and easy use. handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The methanol catalytic cracking reducing atmosphere in this example is produced by a JCL-I methanol catalytic cracking machine produced by the Institute of Applied Chemistry, North China University (formerly North China Institute of Technology).

[0026] Open all the valves on the gas path connecting the methanol catalytic cracker and the reduction furnace, start the methanol catalytic cracker, open the valve of the methanol storage tank and the condensate water valve, set the temperature of the vaporization chamber to 220°C, and the temperature of the reactor to 100°C, and open the vaporization chamber and reactor heating switch to heat up.

[0027] When the temperature of the vaporization chamber rose to 150° C., the liquid feed regulating valve was opened, the flow rate of methanol was set at 60 ml / min, and methanol was introduced into the vaporization chamber.

[0028] After feeding for 15 minutes, the temperature of the reactor was adjusted to 350° C., and the temp...

Embodiment 2

[0038] Open all the valves on the gas path connecting the methanol catalytic cracker and the reduction furnace, start the methanol catalytic cracker, open the valve of the methanol storage tank and the condensate water valve, set the temperature of the vaporization chamber to 220°C, and the temperature of the reactor to 100°C, and open the vaporization chamber and reactor heating switch to heat up.

[0039] When the temperature of the vaporization chamber rises to 150° C., open the liquid feed regulating valve, set the flow rate of methanol to 50 ml / min, and feed methanol into the vaporization chamber.

[0040] After feeding for 15 minutes, the temperature of the reactor was adjusted to 300° C., and the temperature continued to rise.

[0041] Take by weighing 10g nano-zinc oxide with balance, be placed on medicine tray and pave, put into reduction furnace, seal.

[0042] Set the temperature of the reduction furnace to 360°C. After the methanol cracking reduction atmosphere re...

Embodiment 3

[0047] Open all the valves on the gas path connecting the methanol catalytic cracker and the reduction furnace, start the methanol catalytic cracker, open the valve of the methanol storage tank and the condensate water valve, set the temperature of the vaporization chamber to 220°C, and the temperature of the reactor to 100°C, and open the vaporization chamber and reactor heating switch to heat up.

[0048] When the temperature of the vaporization chamber rose to 150° C., the liquid feed regulating valve was opened, the flow rate of methanol was set to 70 ml / min, and methanol was introduced into the vaporization chamber.

[0049] After feeding for 15 minutes, the temperature of the reactor was adjusted to 350° C., and the temperature continued to rise.

[0050] Take 50g nano-zinc oxide with a balance, put it on the medicine tray and pave it, put it into the reduction furnace, and seal it.

[0051] Set the temperature of the reduction furnace to 400°C. After the methanol crack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com