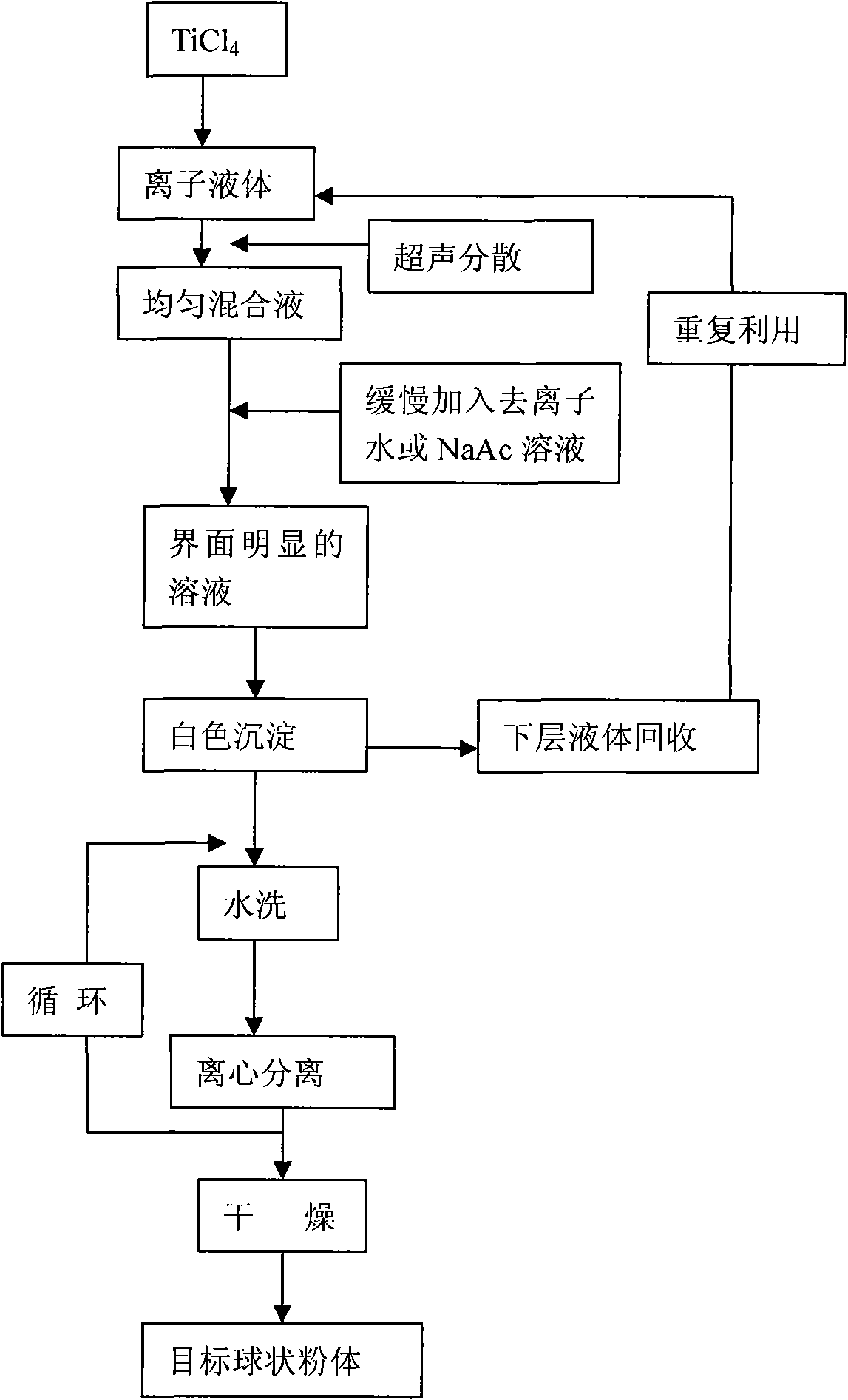

Method for preparing titanium dioxide hollow spherical powder

A hollow spherical, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of uneven particle size, long production cycle, wide distribution, etc., and achieve small environmental pollution, uniform particle size distribution, Wide range of adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

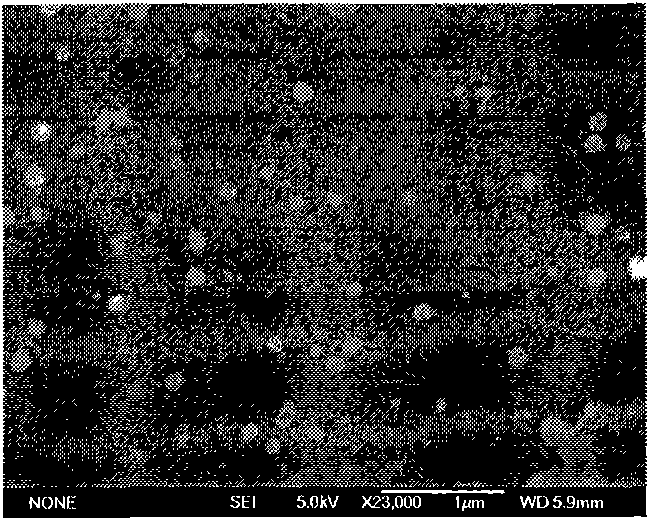

[0037] Prepare TiCl according to the molar concentration of 0.1M 4 The 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid solution was ultrasonically dispersed to form a brownish-red solution; 6ml of TiCl was measured at a volume ratio of 2:3 4 solution and 9ml deionized water. TiCl with higher density 4 The ionic liquid solution was added to a 25ml sample bottle, and then deionized water was slowly added, and there was an obvious interface between the two liquids. The temperature was kept at 288K. After 2 hours, white turbidity was formed, and the precipitate gradually penetrated into the ionic liquid layer. After 24 hours, the liquid still separated after the precipitate settled. Take out the upper layer colorless solution and the lower layer light red solution respectively. The measured pH value of the upper layer solution is less than 1, and the imidazolium salt content of the lower layer solution is relatively high, and the measured pH value is about 1. The lo...

Embodiment 2

[0039] Prepare TiCl according to the molar concentration of 0.5M 4 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid solution, ultrasonically dispersed to form a brownish-red solution; 9ml of TiCl was measured at a volume ratio of 3:2 4 solution and 6ml deionized water. TiCl with higher density 4The ionic liquid solution was added to a 25ml sample bottle, and then deionized water was slowly added, and there was an obvious interface between the two liquids. The temperature was kept at 288K, white turbidity was formed after 2 hours, and the precipitate gradually penetrated into the ionic liquid layer. After 34 hours, the hydrolysis was complete. After the precipitation settled, the upper layer of colorless solution and the lower layer of light red solution were taken out, and the lower layer solution was left for recycling. The white precipitate was separated by centrifugation and washed with water until AgNO 3 Detection without Cl - , washed with alcohol for the la...

Embodiment 3

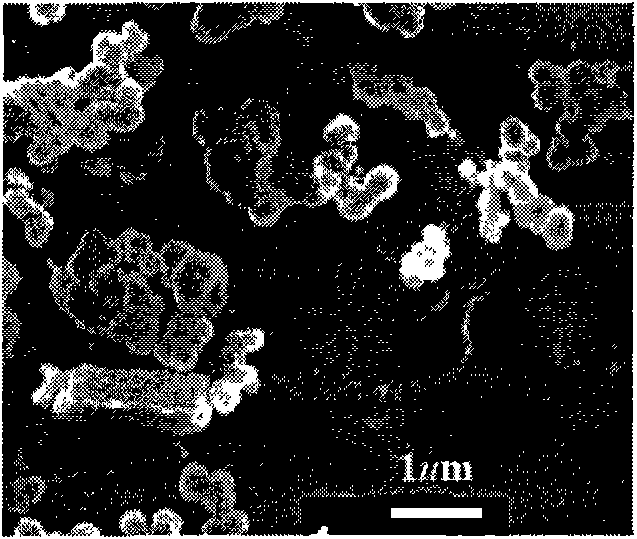

[0041] Prepare TiCl according to the molar concentration of 1.0M 4 1-butyl-3-methylimidazolium tetrafluoroborate ionic liquid solution, ultrasonically dispersed to form a brownish-red solution; 9ml of TiCl was measured at a volume ratio of 3:2 4 solution and 6ml deionized water. TiCl with higher density 4 The ionic liquid solution was added to a 25ml sample bottle, and then deionized water was slowly added, and there was an obvious interface between the two liquids. The temperature was kept at 288K, and the hydrolysis was complete after 46 hours. After the precipitation settled, the upper layer of colorless solution and the lower layer of light red solution were taken out respectively, and the lower layer solution was left for recycling. The white precipitate was separated by centrifugation and washed with water until AgNO 3 Detection without Cl - , washed with alcohol for the last time, and then the precipitate was dried in an oven at a temperature of 325K for a holding t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com