Large-doping-amount fly ash cement and preparation method thereof

A high-volume fly ash cement technology is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc. It can solve the problems of large discharge of fly ash and red mud, and achieve a simple and efficient production process. Low cost and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

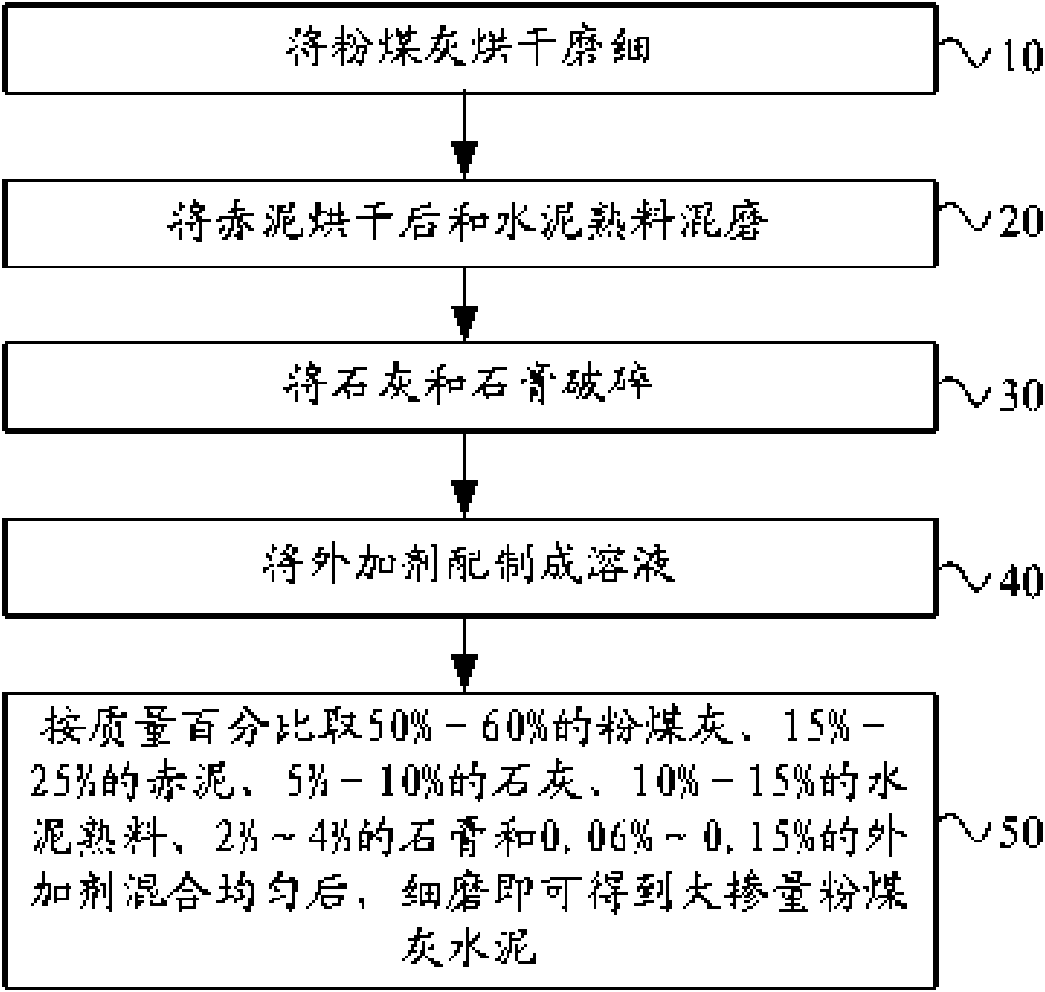

[0026] figure 1 It is a schematic flow chart of the method for preparing large-volume fly ash cement of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0027] Step 10, drying and grinding the fly ash.

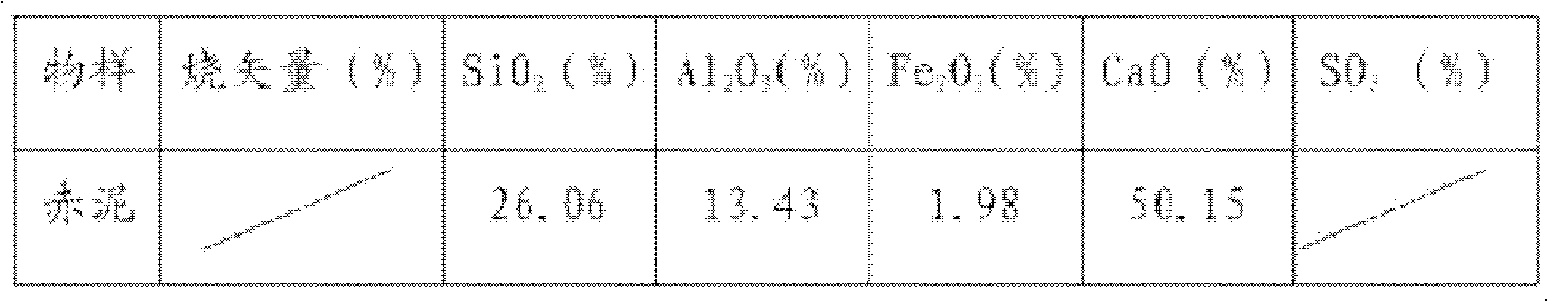

[0028] Dry the fly ash until the water content is less than 2%, and finely grind it until the particle size is 0.08 mm and the residue on the square hole sieve is 2% to 3%. The fly ash of the present invention adopts the fly ash discharged from Zhungeer Guohua Power Plant, and its chemical composition is as shown in Table 1.

[0029] Table 1 Chemical composition of fly ash discharged from Zhungeer Guohua Power Plant

[0030] object

Burn vector (%)

...

PUM

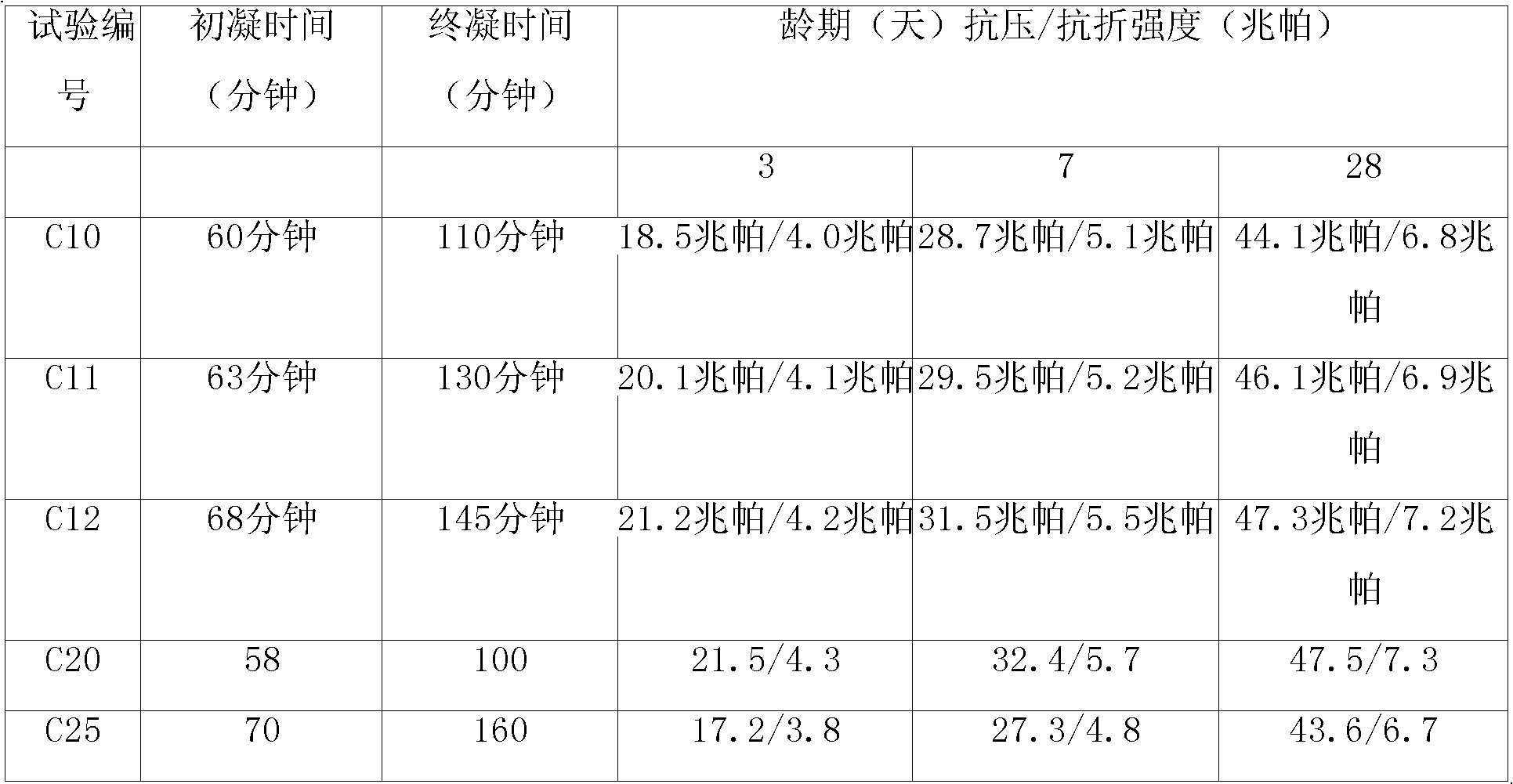

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com