Emulsified ink for porous printing

A technology of emulsified ink and stencil printing, which is applied in the fields of ink, application, household appliances, etc. It can solve the problems of insufficient fixability and drying speed of colorants, slow drying speed of ink, etc., and achieve excellent fixability and prevent ink from curing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0156] Although the present invention will be described more specifically based on examples, the present invention is not limited to the following examples.

[0157] In the following examples and comparative examples, "the iodine value of the drying oil" and "the weight average molecular weight of the resin" were measured according to the following methods.

[0158]

[0159] The iodine value was measured according to JIS K 0070.

[0160]

[0161] The weight-average molecular weight of the resin was measured by gel permeation chromatography and converted to polystyrene to obtain it.

Embodiment A-1~A-19 and comparative example A-1~A-10

[0163] -Preparation of emulsified ink for stencil printing-

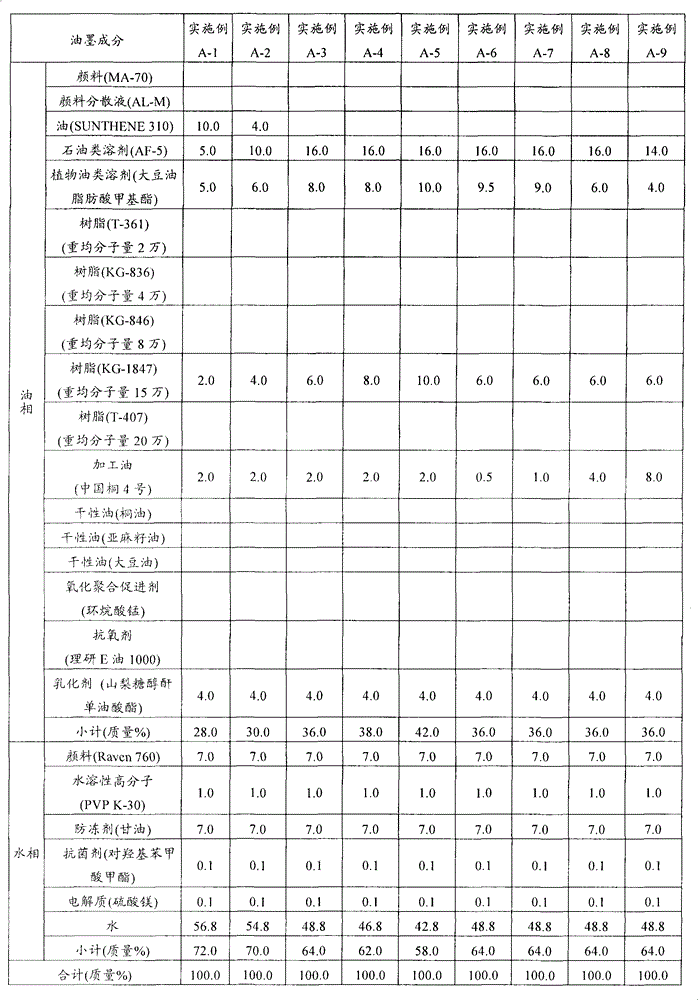

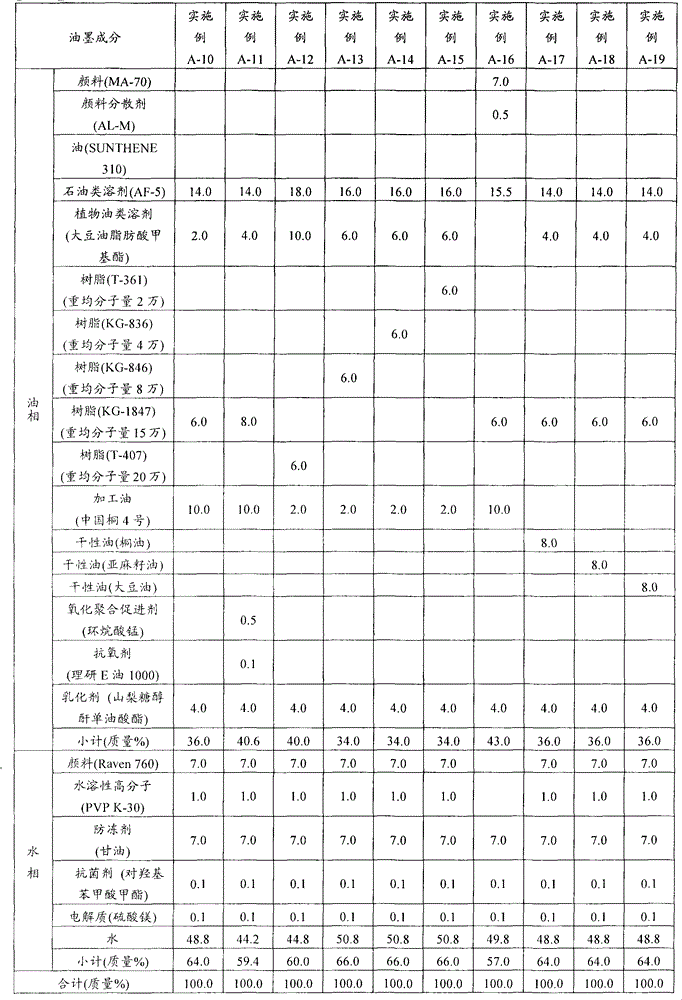

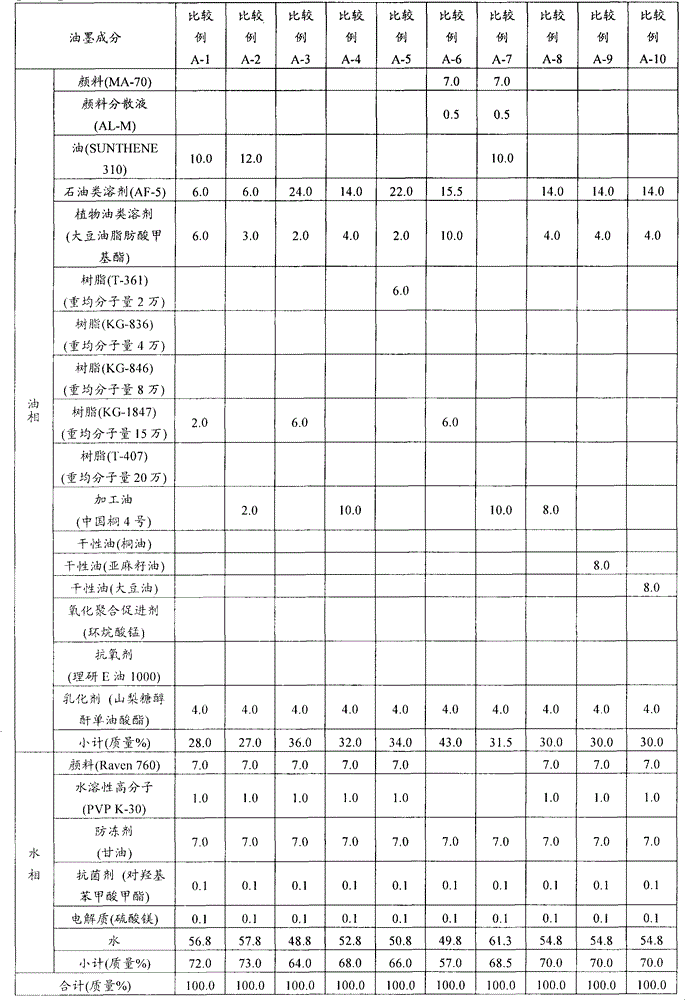

[0164]Utilize the same method as preparing traditional emulsified ink to prepare oil phase and water phase according to the ink formulation (unit is mass %) shown in Table 1~Table 3, make two-phase emulsification in known emulsifying machine, thereby make embodiment A Emulsion inks for stencil printing of -1 to A-19 and Comparative Examples A-1 to A-10.

[0165] The specific operation is as follows: in embodiment A-16 and comparative examples A-6 and A-7, the colorant, oil and insoluble colorant dispersant are ground by a three-roll machine to prepare the insoluble colorant dispersion, and the insoluble colorant A colorant dispersion (hereinafter referred to as insoluble colorant dispersion) is added to an emulsifying surfactant, oil, drying oil (or processing oil) and varnish such as a resin to form an oil phase, and water is added to the oil phase. , antifreeze, antibacterial agent, electrolyte or water-soluble r...

Embodiment B-1

[0240]After adding and premixing the following components, they were dispersed using a bead mill to obtain an aqueous phase, wherein the premixed components were as follows: 7.0 parts by mass of Raven 760 (manufactured by Columbian) as a pigment, 1.0 parts by mass PVP K-30 (manufactured by BASF Corporation) as a water-soluble polymer, 7.0 parts by mass of glycerin (manufactured by Kao Corporation) as an antifreeze agent, 0.1 parts by mass of methylparaben (manufactured by Kanto Chemical Co., Ltd.) as an antibacterial agent, 0.1 parts by mass of magnesium sulfate (manufactured by Kanto Chemical Co., Ltd.) and 56.8 parts by mass of ion-exchanged water as electrolytes. Further, the water phase is stirred and mixed into the pre-prepared oil phase for emulsification, thereby obtaining an emulsified ink for stencil printing. Among them, the oil phase contains the following components: 10.0 parts by mass of SUNTHENE 310 (manufactured by SUNOIL Corporation) as an oil, 5.0 parts by mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| minimum film forming temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com