Method for measuring organic carbon content in sodium aluminate serosity

A determination method and technology of sodium aluminate are applied in the direction of chemical analysis by titration, analysis of materials, instruments, etc., which can solve the problems of increased impurity content of finished alumina, difficulty in solid-liquid separation, and reduced dissolution rate, etc. Simple and effective method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

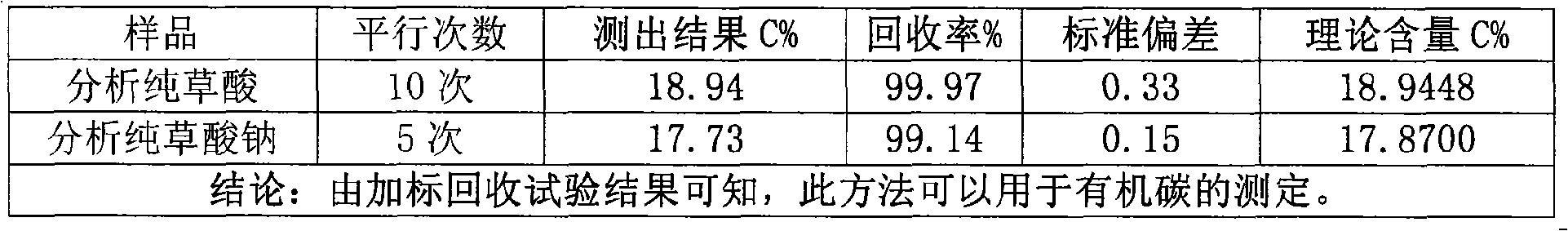

Examples

Embodiment

[0012] 1. Take the sodium aluminate slurry sample into the porcelain boat, adopt the combustion method, use pickled asbestos as the covering, first dry at low temperature for 30-50 minutes, gradually raise the temperature to 900°C, and burn it under the condition of oxygen Burn for 2 minutes, absorb the generated CO with potassium hydroxide 2 , measure the total carbon content in the material with the gas volumetric method (specific operation and testing device are as follows): the total carbon content in organic carbon and sodium carbonate potassium carbonate.

[0013] Check the air tightness: before working, check whether there is any air leakage in the carbon measuring instrument section by section.

[0014] 1) Turn the piston to make the absorption bottle communicate with the measuring gas tube, and use the level bottle to adjust the absorption liquid to the top of the buoy, close the piston, and the absorption liquid level should not drop at this time, otherwise the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com