Automatic gear shifting control system of motor in electric automobile

A technology of automatic shifting and control system, applied in motor generator control, AC motor acceleration/deceleration control, electric vehicle and other directions, can solve the problems of difficult adjustment of friction torque, short service life of synchronizer, easy damage to friction surface, etc. Guarantee fast response and precise control, good electromagnetic compatibility performance, and ensure the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

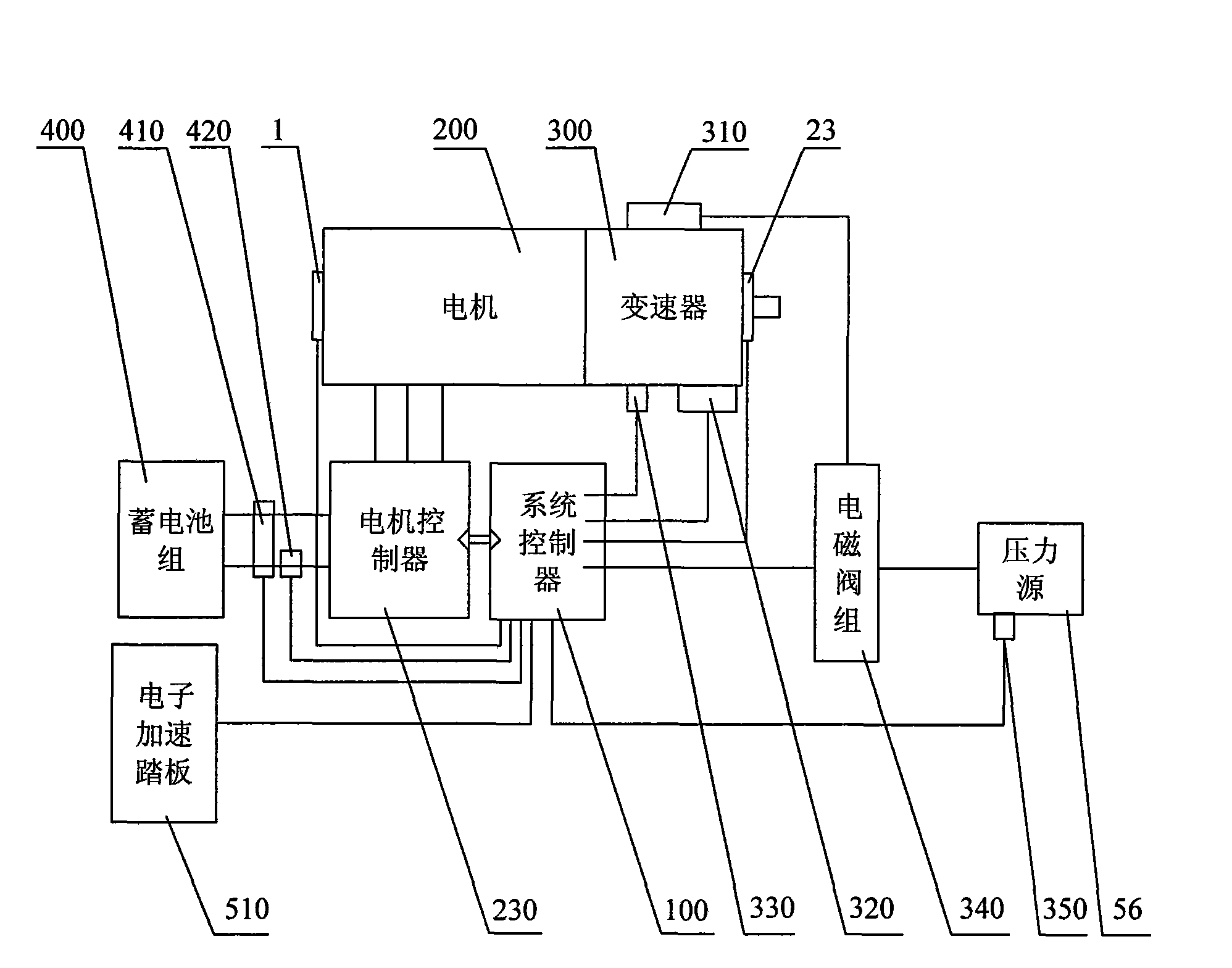

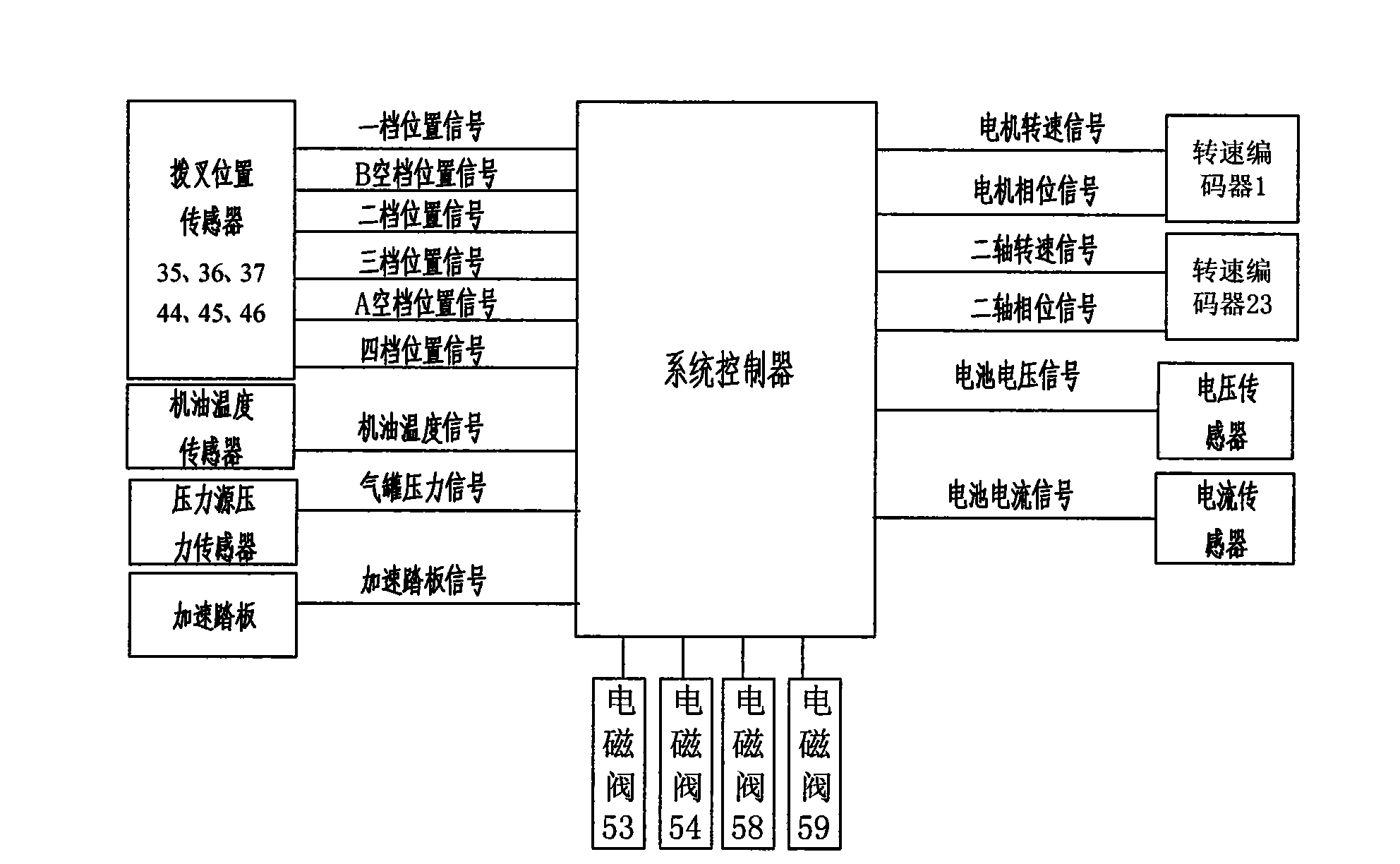

[0023] 1. Control system structure

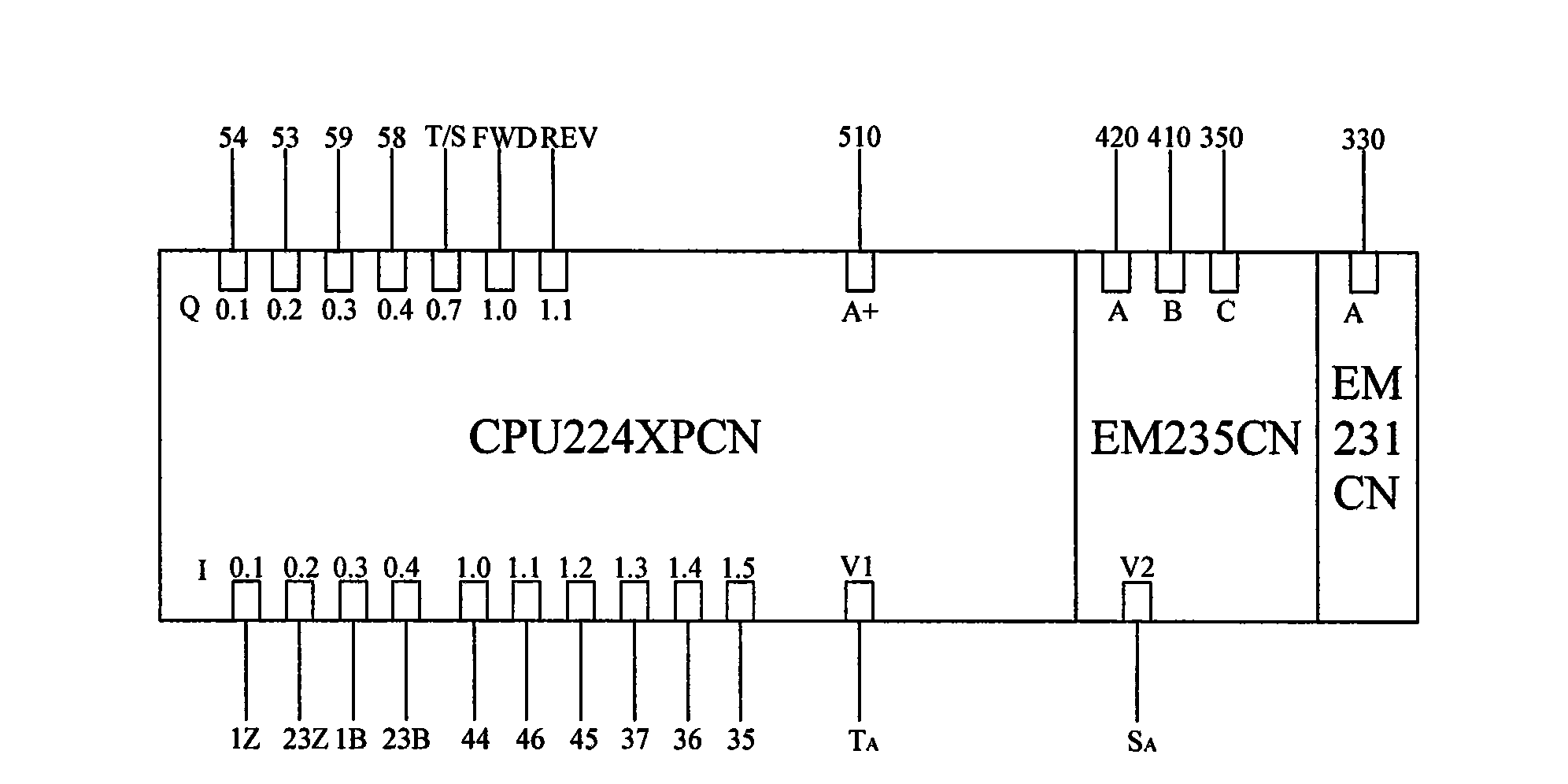

[0024] Such as figure 1 , figure 2 , image 3As shown, the electric vehicle motor automatic variable speed control system includes a motor controller 230, a system controller 100, a battery voltage sensor 410, a battery current sensor 420, a first rotational speed encoder 1, a second rotational speed encoder 23, a fork position Sensor group 320, transmission oil temperature sensor 330, pressure source pressure sensor 350; system controller 100 is composed of microprocessor CPU224XPCN, module EM235CN and module EM231CN to form a modular structure, module EM235CN is located between microprocessor CPU224XPCN and module EM231CN (system Controller 100 is a modular structure, is made up of CPU224XPCN+EM235CN+EM231CN, Siemens); Motor controller 230 is: FRENIC5000VG7S series, Japanese Fuji Electric Company; , corresponding to 2 output terminals) are connected to the 2 output terminals of the battery pack 400, the power output terminals of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com