Levetiracetam tablet and preparation method

A technology of tablets and disintegrants, applied in the field of levetiracetam tablets and its preparation, can solve the problems of poor mechanical compressibility and difficulty in tablet compression, and achieve stable quality and easy industrial promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

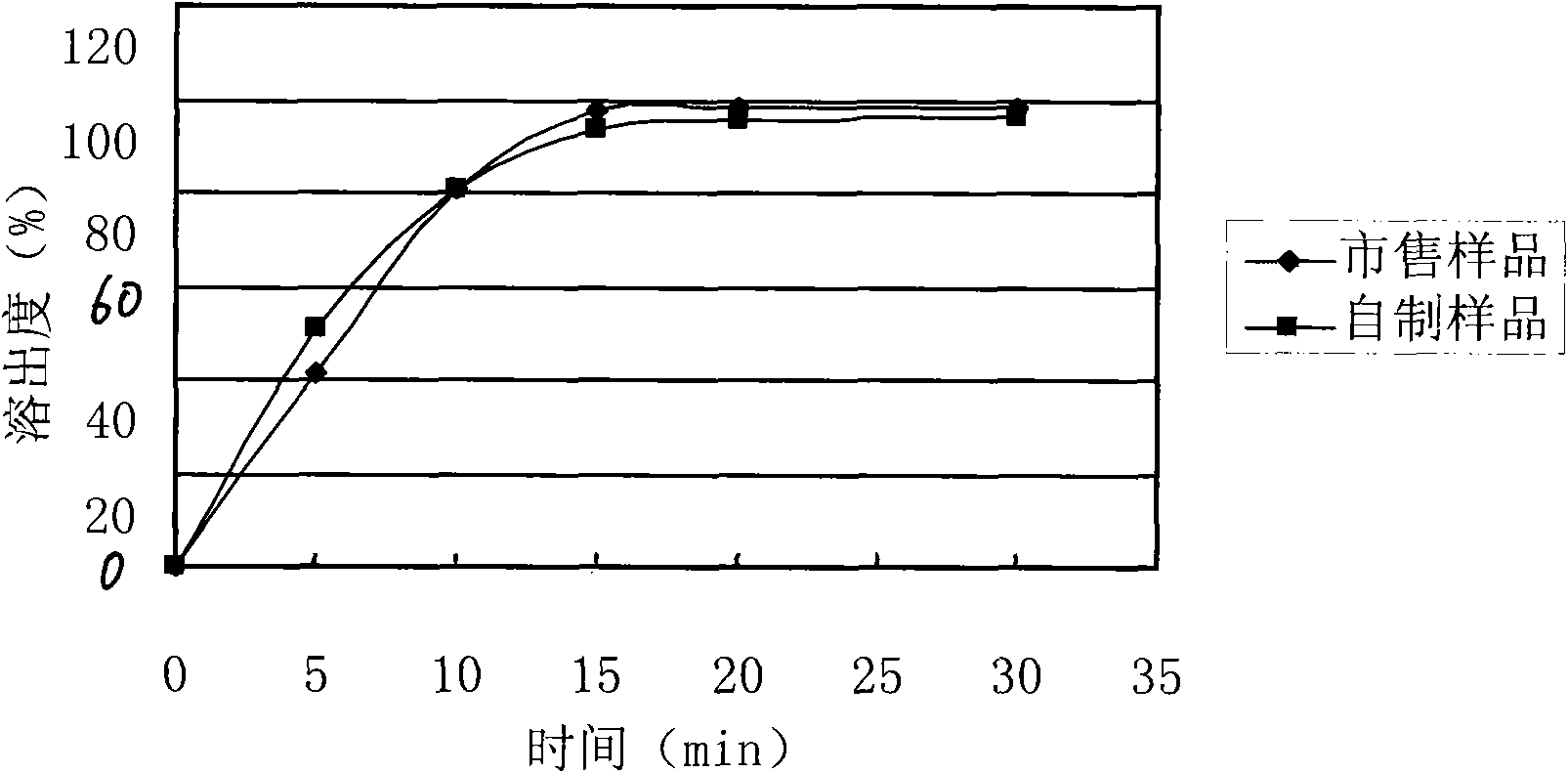

Embodiment 1

[0022] Prescription composition (dosage per 1000 tablets, specification 250mg)

[0023]

[0024] Mix levetiracetam with polyethylene glycol 4000, microcrystalline cellulose, pregelatinized starch, and croscarmellose sodium, and add 5% hypromellose aqueous solution for granulation. Dry, add additional part of microcrystalline cellulose, pregelatinized starch, croscarmellose sodium and precipitated silicon dioxide, magnesium stearate, mix, compress with conventional tablet machine, use Opadry (Opadry) ) 85G60729 for coating.

Embodiment 2

[0026] Prescription composition (dosage per 1000 tablets, specification 250mg)

[0027]

[0028] Mix levetiracetam with polyethylene glycol 4000, microcrystalline cellulose, starch, and croscarmellose sodium, and add 2% hypromellose aqueous solution to granulate, dry, add Add part of microcrystalline cellulose, pregelatinized starch, croscarmellose sodium, precipitated silicon dioxide, and magnesium stearate, mix, and compress with a conventional tablet machine, using Opadry 85G60729 Coated and ready to serve.

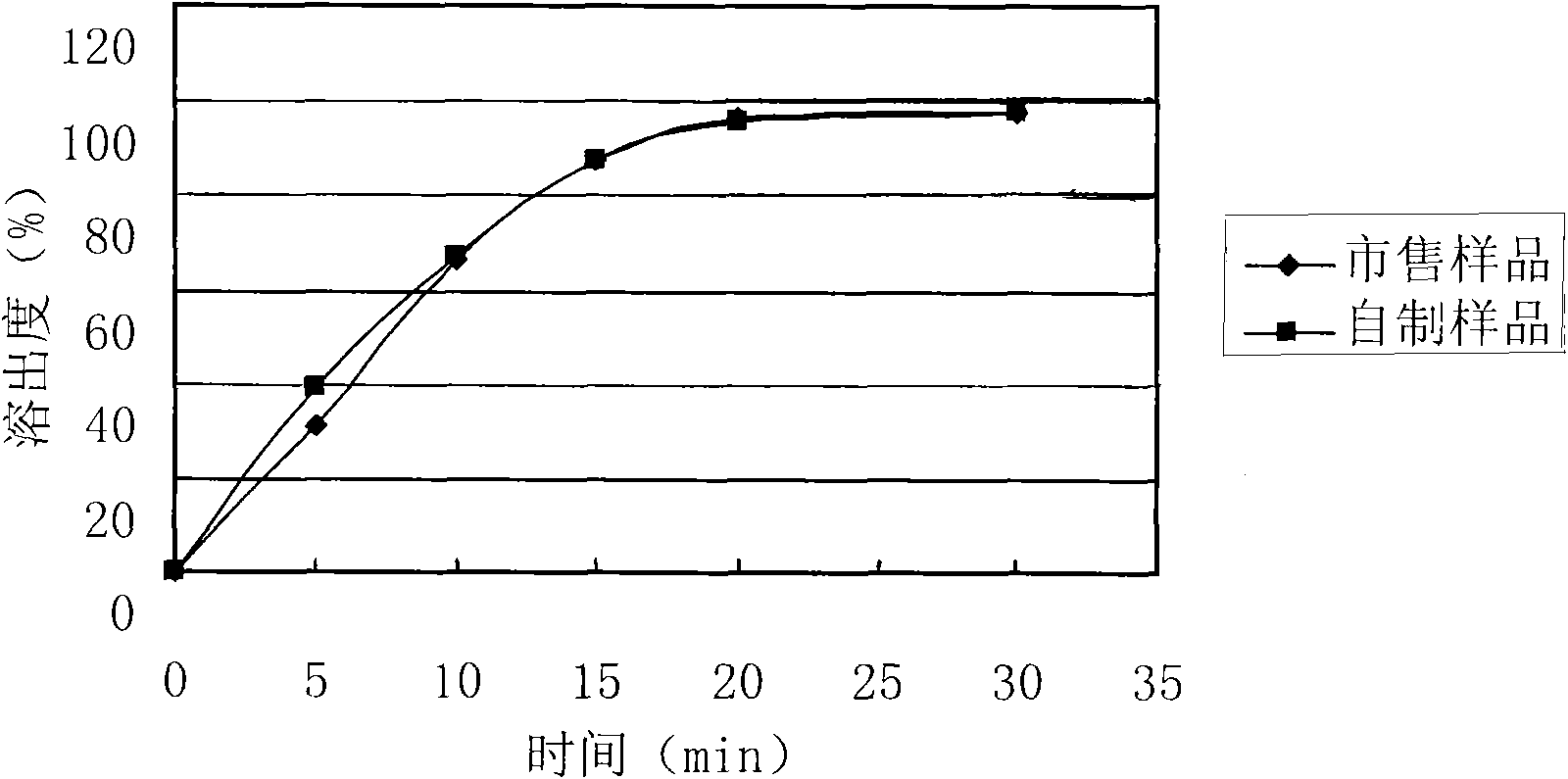

Embodiment 3

[0030] Prescription composition (dosage per 1000 tablets, specification 500mg)

[0031]

[0032] Mix levetiracetam with polyethylene glycol 4000, microcrystalline cellulose, pregelatinized starch, and croscarmellose sodium, and add 3% hypromellose aqueous solution for granulation. Dry, add additional part of microcrystalline cellulose, pregelatinized starch, croscarmellose sodium and precipitated silicon dioxide, magnesium stearate, mix, compress with conventional tablet machine, use Opadry (Opadry) ) 85G62984 for coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com