Welding rod for welding hard alloy and steel parts and welding method thereof

A technology of hard alloy and welding rod, applied in the direction of welding medium, welding accessories, welding/cutting medium/material, etc., can solve the problems of increased risk and low efficiency, and achieve the effect of stable arc, beautiful shape and good welding process performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

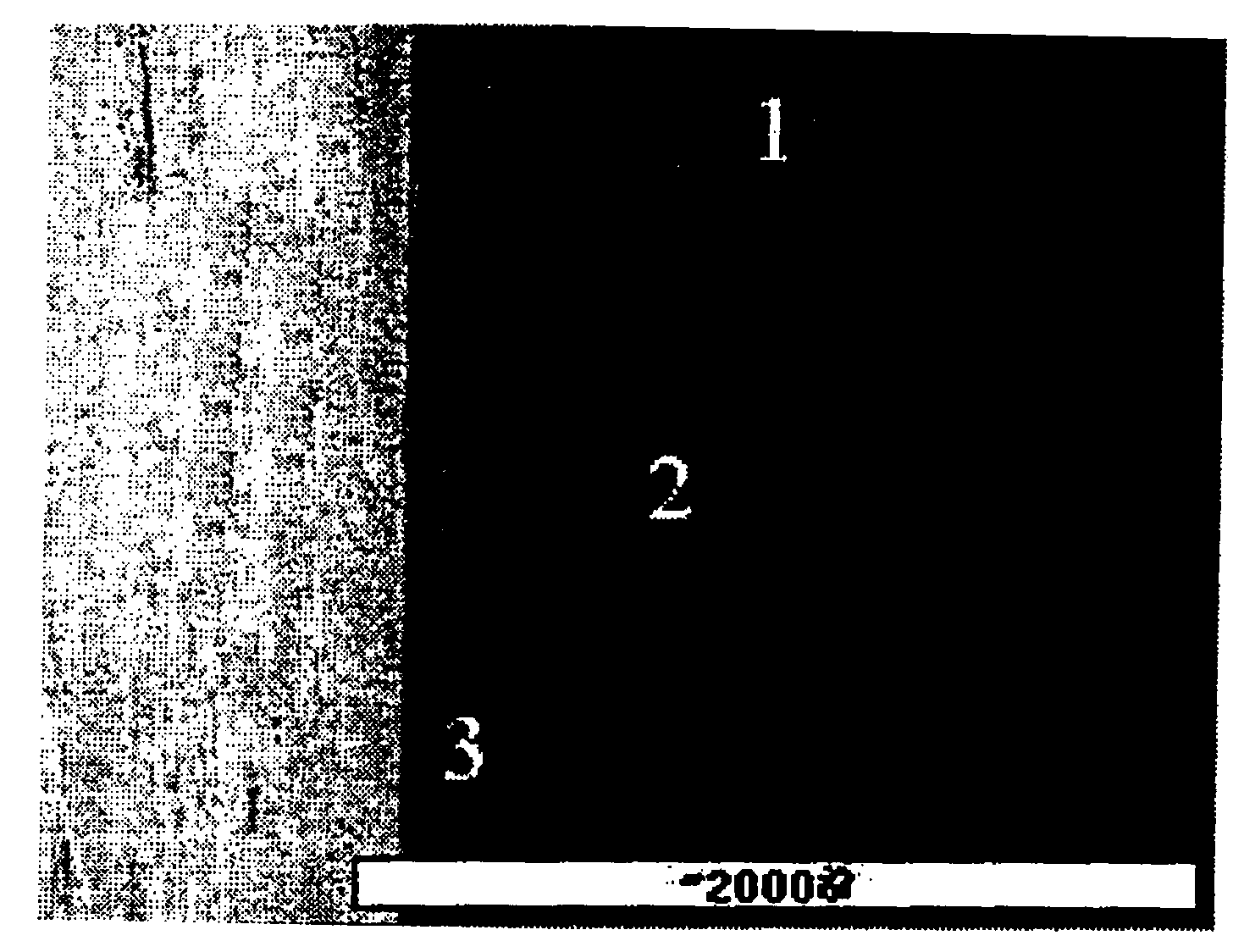

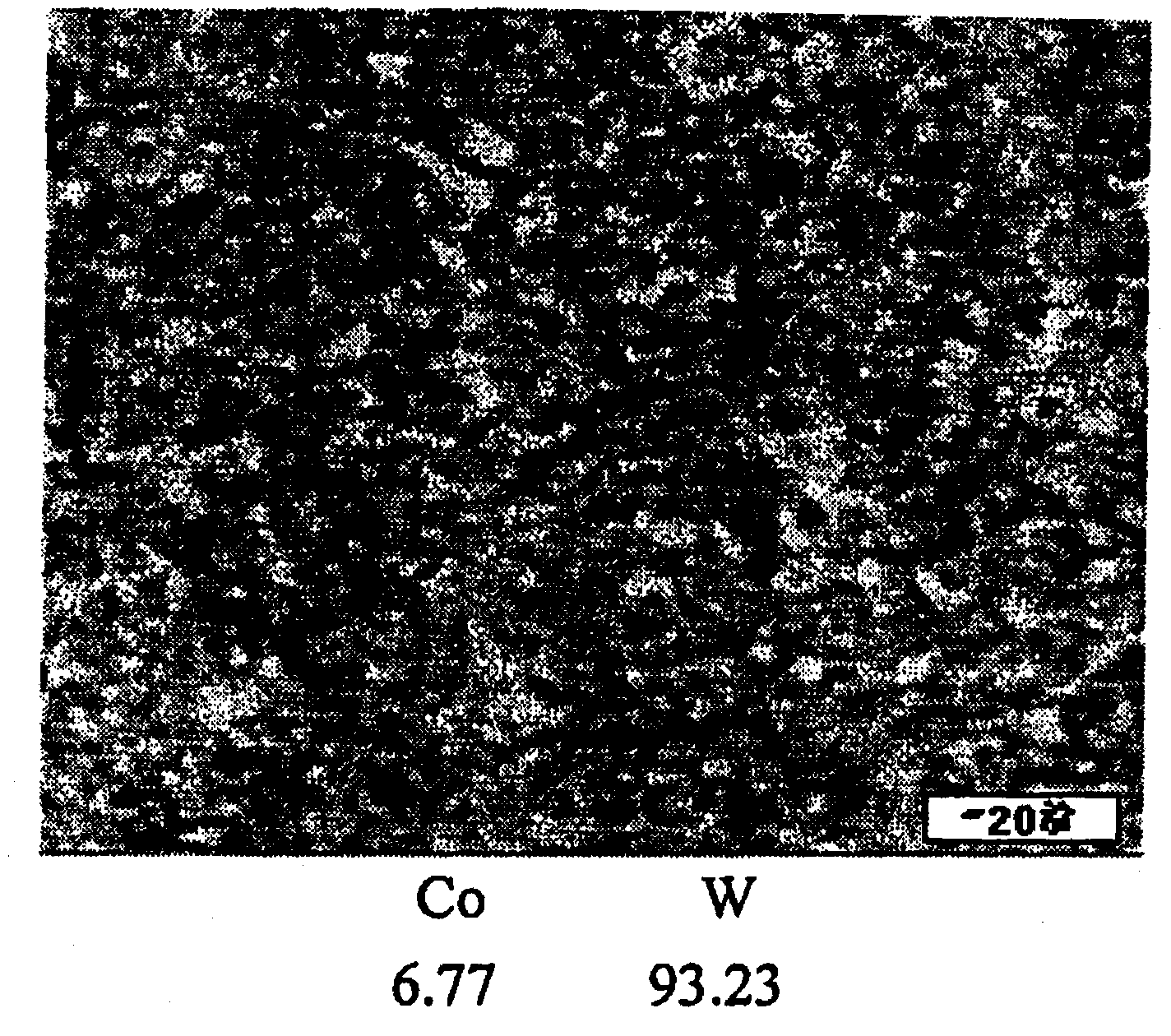

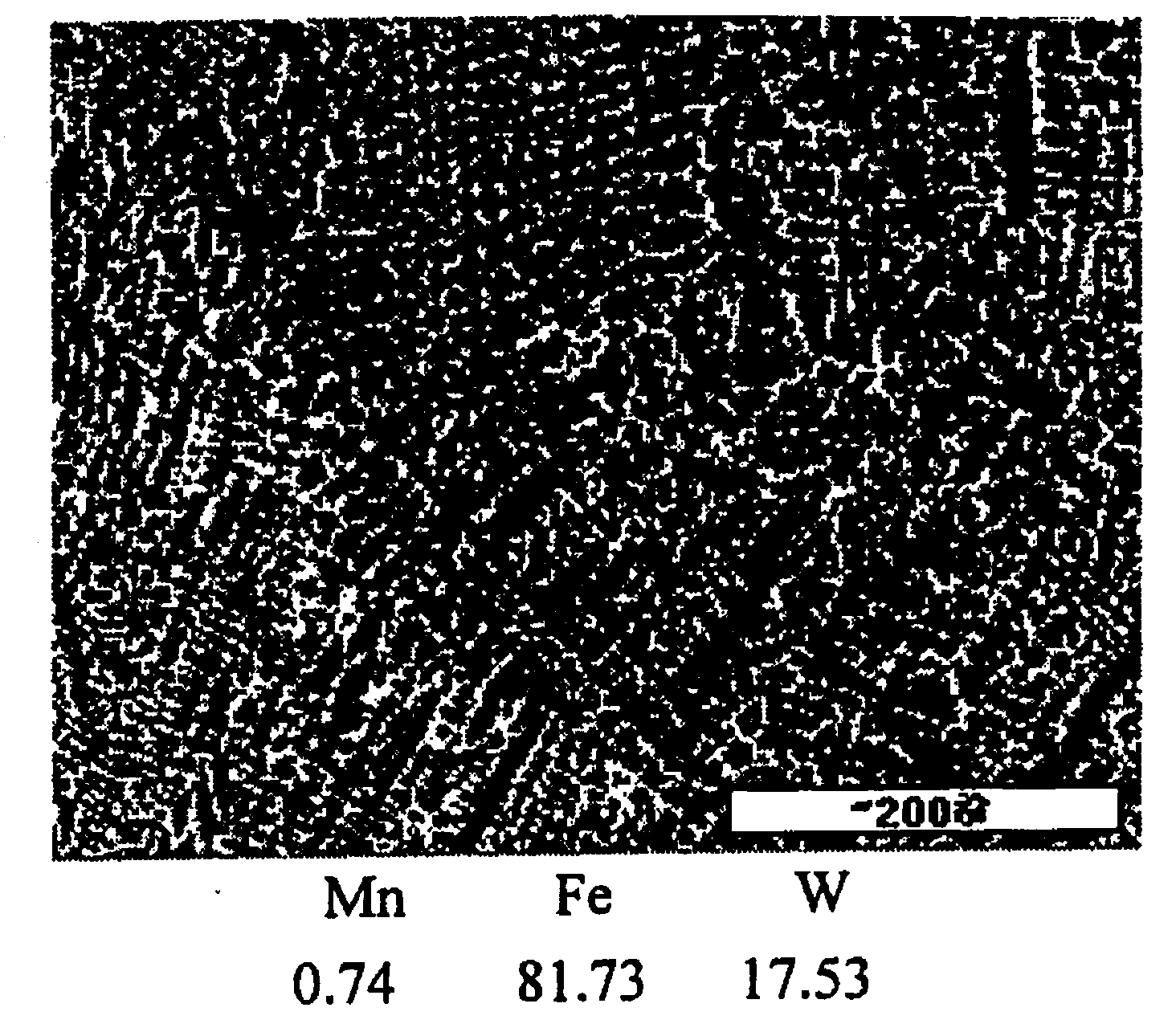

[0022] According to the composition range of the coating of the present invention, the welding rod is prepared, and the specific formula by weight is: W: 51, C: 3, CaCO 3 : 24, CaF 2 : 11, SiO 2 : 3, TiO 2 : 3, rare earth: 1.5, iron powder: 3.5. By welding the 40SiMn cast steel drill body and the cemented carbide sheet, the cemented carbide sheet and the cast steel drill body are welded. The microscopic morphology of the weld after welding is shown in Fig. Figure 1 to Figure 5 .

Embodiment 2

[0024] According to the composition range of the coating of the present invention, the welding rod is prepared, and the specific formula by weight is: W: 52, C: 2, CaCO 3 : 27, CaF 2 : 9, SiO 2 : 4, TiO 2 : 3, rare earth: 1.5, iron powder: 1.5.

Embodiment 3

[0026] Weld the above welding rod on the 40SiMn cast steel drill bit body and the hard alloy sheet. The welding method is to preheat the steel parts in a box-type heating furnace to 400°C-450°C before welding, and heat the hard alloy sheet 15 minutes before welding. Put it in the furnace and preheat it to 250°C-300°C, use an ordinary DC welding machine, and the welding current is: 120A~140A. Immediately after welding, place the welded piece in an incubator at about 300°C, and use the waste heat of the workpiece to keep it warm , the workpiece is naturally cooled in the incubator until it is taken out at room temperature. It can weld the cemented carbide sheet with the cast steel drill bit body. The machining requirements for the drill trouser body (cutter body) are not high during welding. The welding part can even be cast and formed at one time. The welding metal temperature is 500-600 °C It has red hardness and resistance under high temperature, and the welding process perfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com