Method for removing total nitrogen in household garbage leachate

A technology for domestic waste and leachate, applied in the field of environmental protection, can solve the problems of high denitrification cost, high treatment cost and high water quality requirements, and achieve the effect of improving denitrification efficiency and improving the degree of denitrification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

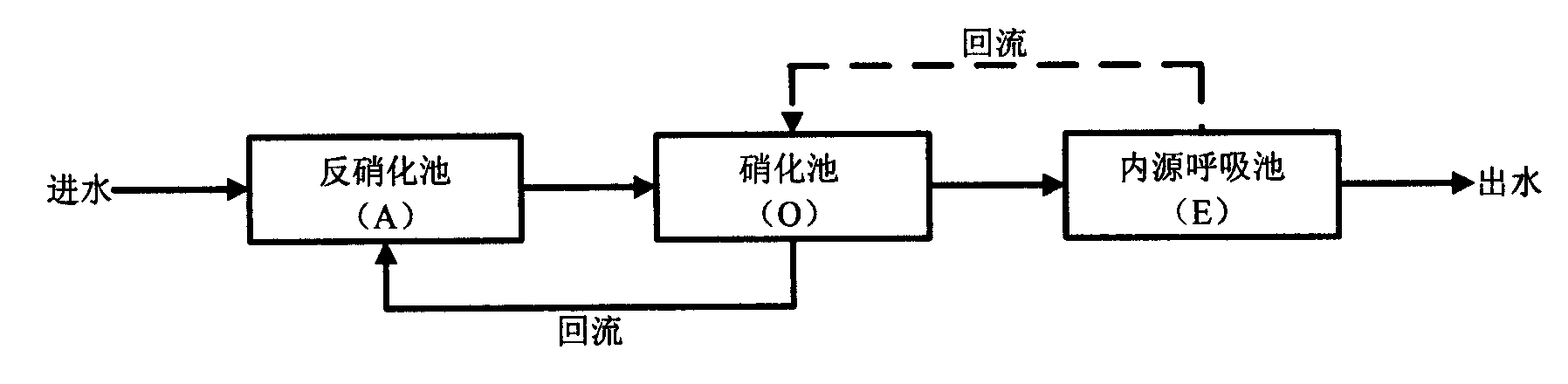

[0025] A method for removing total nitrogen in domestic waste leachate, including denitrification treatment, nitrification treatment and endogenous respiration treatment, the temperature of denitrification treatment, nitrification treatment and endogenous respiration treatment is 30 ° C, and the C / N in denitrification treatment 3:1, the reflux ratio from nitrification to denitrification is 500%, and the reflux ratio from endogenous respiration to nitrification is 200%. The time of denitrification treatment is 2 hours, the time of nitrification treatment is 4 hours, and the time of endogenous respiration treatment is 4 hours. The removal rate of ammonia nitrogen in the effluent is 98%, and the removal rate of total nitrogen reaches 92%.

Embodiment 2

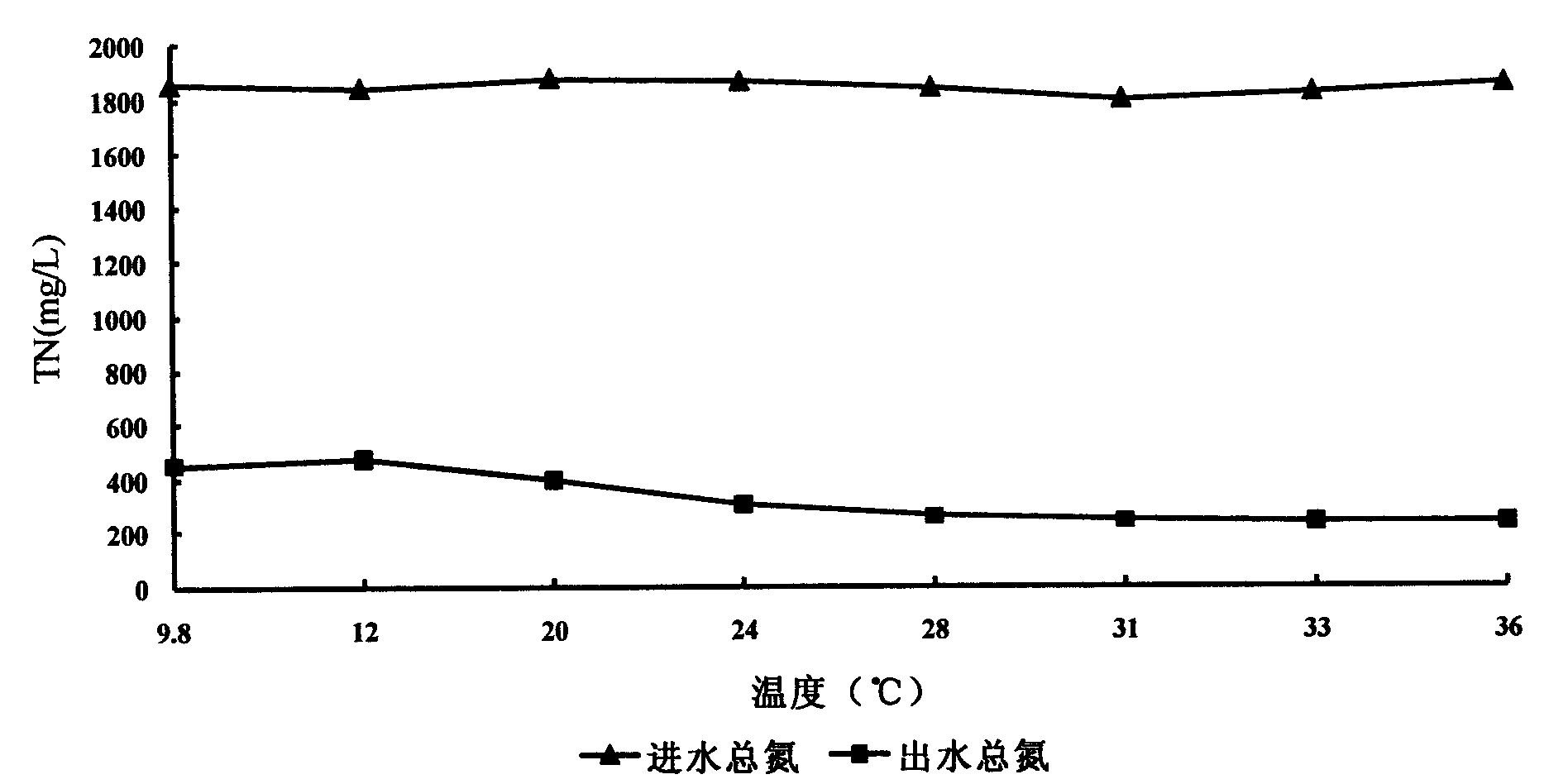

[0027] The effect of temperature on nitrification and denitrification speed is directly related to the type of reaction equipment and process conditions. Generally, the optimum temperature for nitrifying and denitrifying bacteria is 30°C. From figure 2 It can be seen that the removal rate of total nitrogen increases gradually with the increase of temperature, and there is no significant change in the removal of total nitrogen after 30 °C. The whole process can run stably without external heat source.

Embodiment 3

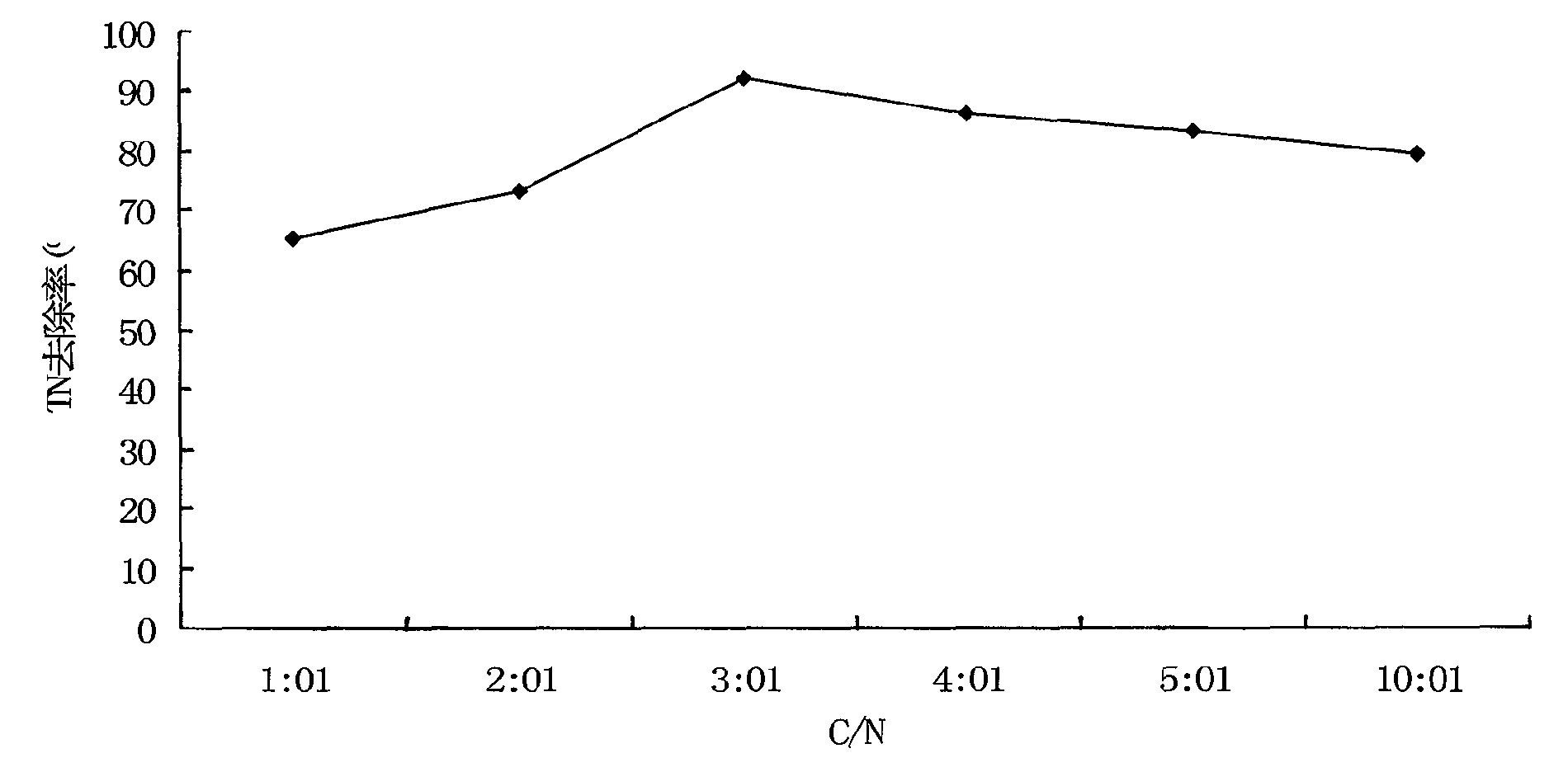

[0029] In the denitrification process, C / N will affect the proportion of nitrifying bacteria in activated sludge. Because nitrifying bacteria are autotrophic microorganisms, in the process of metabolism

[0030] No organic matter is needed, so the smaller the COD / TKN in the sewage, the easier the nitrification reaction will be. But the denitrification process is a process that requires a carbon source. Therefore, an appropriate carbon-nitrogen ratio is the key to determine the stable operation of the process. From image 3 It can be seen that when the carbon-nitrogen ratio is maintained at 3:1, the removal rate of the system can reach more than 92%. It can be seen that compared with the traditional denitrification process, the carbon-nitrogen ratio is relatively low, which can fully meet the low carbon-nitrogen ratio of landfill leachate. The status quo, without the need for additional carbon sources.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com