Rapid preparation method of magnesium diboride bulk

A magnesium diboride, rapid technology, applied in the field of rapid preparation of magnesium diboride superconducting bulk materials, can solve the problems of increasing or unfavorable critical current density of magnesium diboride, so as to simplify the process flow and increase the critical current density , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

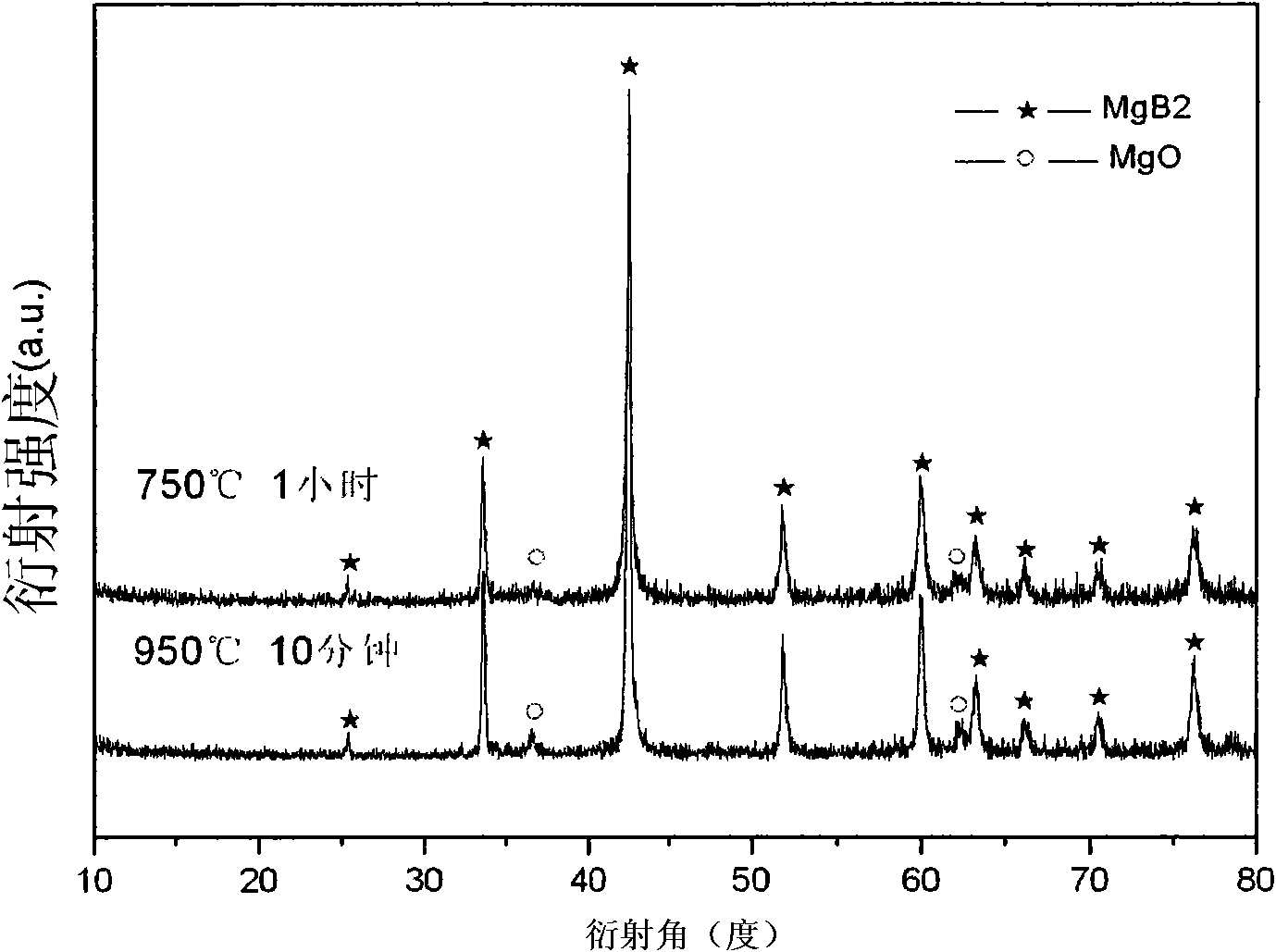

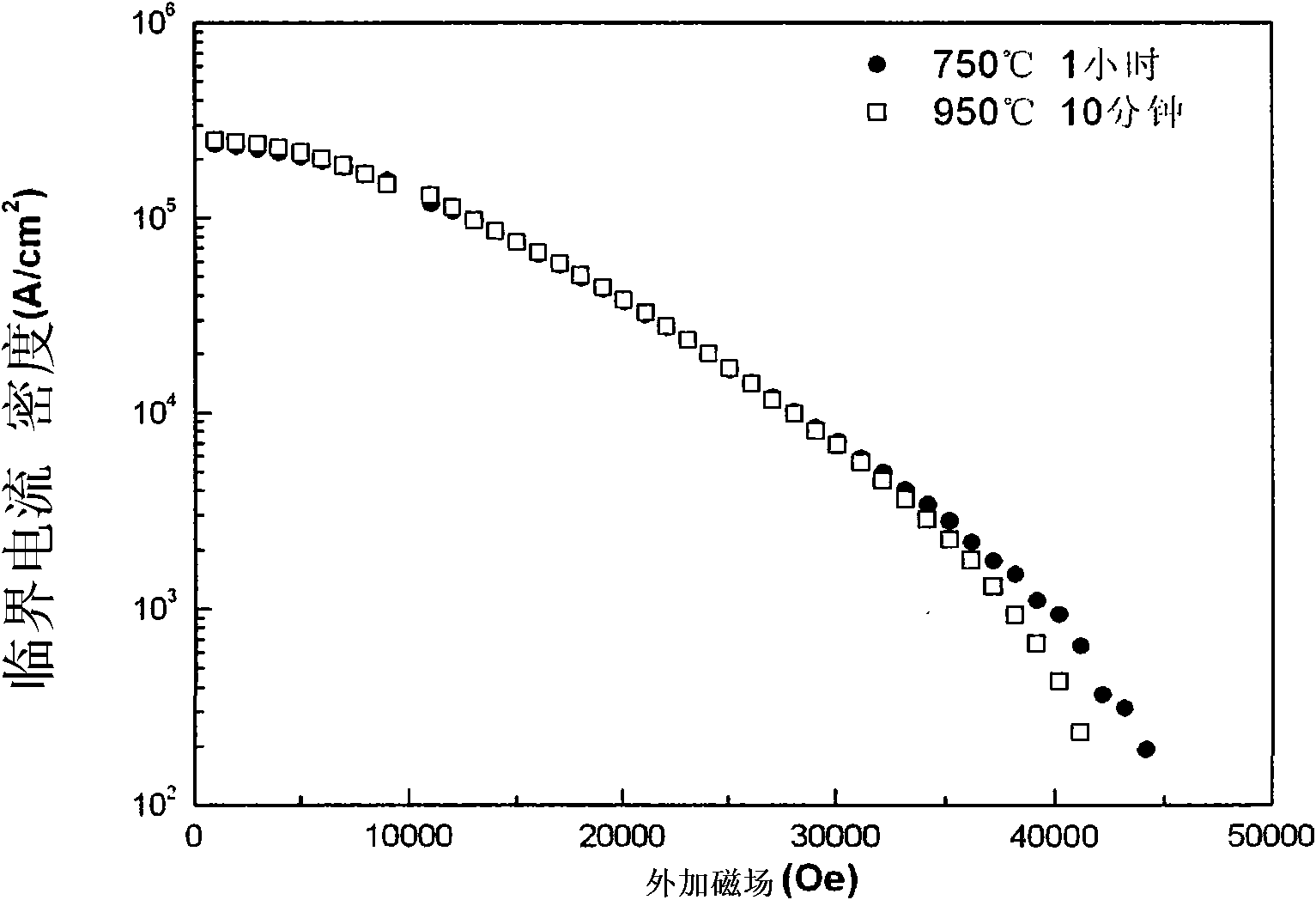

Embodiment 1

[0034] The magnesium powder and the boron powder with a purity of 99.8% and a particle size of 325 mesh are uniformly mixed according to the atomic ratio of magnesium and boron of 1:2, and are uniformly mixed by ball milling, manual grinding or ultrasonic dispersion. Fill the fully mixed powder into a stainless steel pipe (SUS304), compact and fill the mixed powder, press both ends of the steel pipe with a press, and seal it with argon arc welding. Put the packaged steel pipe into the tube sintering furnace. The temperature of the tube furnace is preset at 950°C, and the sample reaches the preset temperature within 70 seconds. After 10 minutes, the sample is taken out of the furnace and cooled to room temperature naturally to obtain a pure magnesium diboride superconductor prepared by the PIT method. blocks. The sample has a self-field Jc of 2×10 5 A / cm 2 , the irreversible field is greater than 4 Tesla.

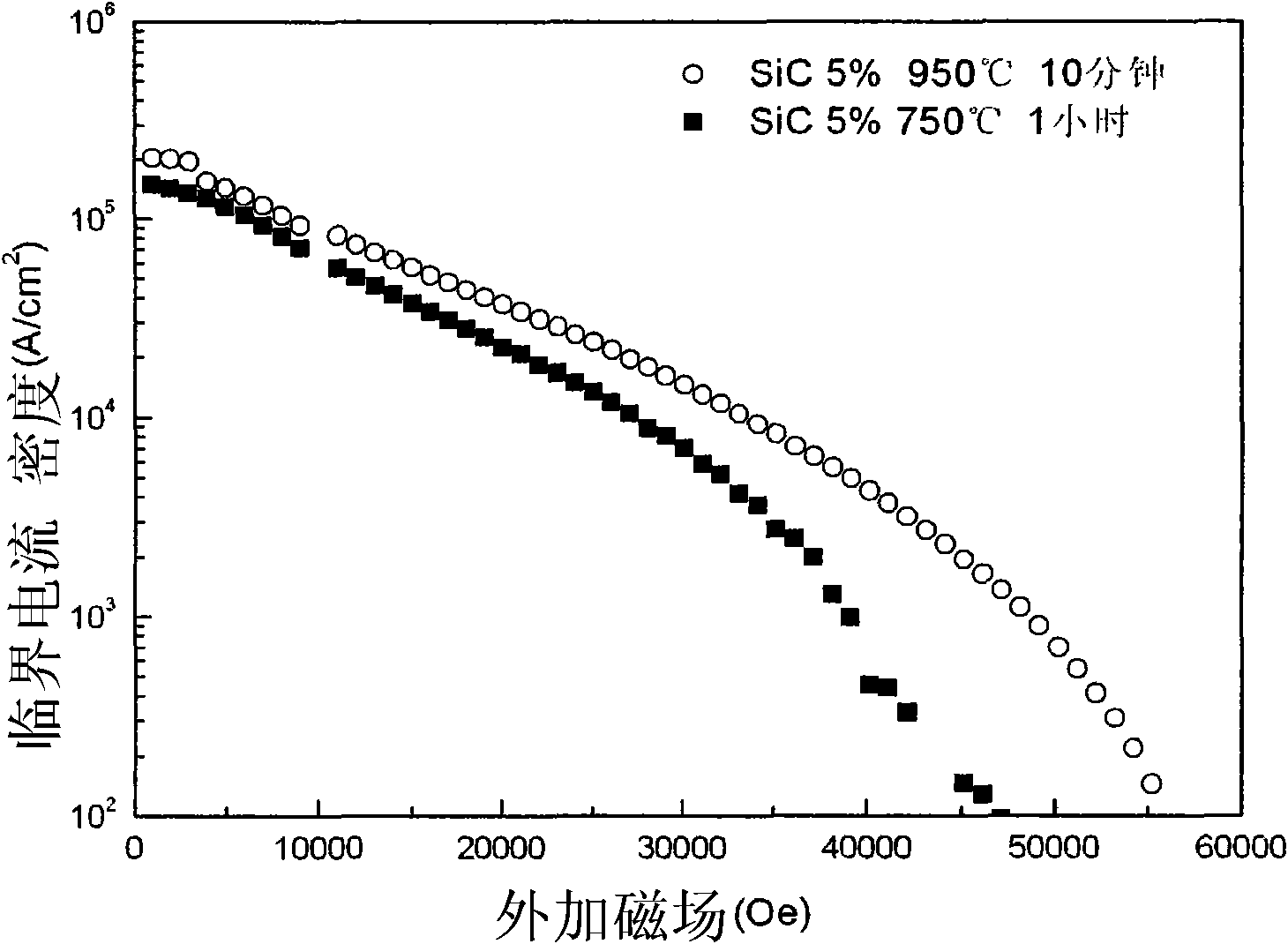

Embodiment 2

[0036]Mix the magnesium powder and boron powder with a purity of 99.8% and a particle size of 325 mesh according to the atomic ratio of magnesium and boron of 1:2, and add 5% by mass ratio of nano-silicon carbide, and use ball milling, manual grinding or ultrasonic dispersion to mix evenly . Fill the fully mixed powder into a stainless steel pipe (SUS304), compact and fill the mixed powder, press both ends of the steel pipe with a press, and seal it with argon arc welding. Put the packaged steel pipe into the tube sintering furnace. The temperature of the tube furnace is preset at 950°C, and the sample reaches the preset temperature within 70 seconds. After 10 minutes, the sample is taken out of the furnace and cooled to room temperature naturally to obtain the doped silicon carbide diboride prepared by the PIT method. Magnesium superconducting bulk. The sample has a self-field Jc of 2×10 5 A / cm 2 , the irreversible field is about 5.5 Tesla.

Embodiment 3

[0038] Mix the magnesium powder and boron powder with a purity of 99.8% and a particle size of 325 mesh according to the atomic ratio of magnesium and boron of 1:2, and add 8% by mass ratio of nano-silicon carbide, and use ball milling, manual grinding or ultrasonic dispersion to mix evenly . Put the fully mixed powder into a stainless steel mold for tabletting, wrap and seal the green compact with a tantalum sheet, and put it into a sample boat. The sample boat was then placed into a tube furnace. The temperature of the tube furnace was preset at 830°C, and the sample reached the preset temperature within 70 seconds. After 15 minutes, the sample was taken out of the furnace and cooled naturally to room temperature to obtain a pure magnesium diboride superconducting block. The sample has a self-field Jc of 1.5×10 5 A / cm 2 , the irreversible field is about 6 Tesla.

[0039] Use the existing method to prepare magnesium diboride block material as a comparison, and the specifi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com