Boiler biomass fuel and preparation method thereof

A biomass fuel, boiler fuel technology, applied in waste fuel, fuel, solid fuel and other directions to avoid pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] In the process of producing penicillin, a pharmaceutical company produces 8,900 tons of mycelium or / and fungal residue raw materials with a water content of 80% per year. In this embodiment, the mycelium and fungal residue are made into boiler biomass fuel. It should be noted that the present invention adopts the waste produced when the enterprise produces antibiotics. The waste can be mycelium or mycelia, or a mixture of mycelium and mycelium, and the mixing ratio of the two is not limited.

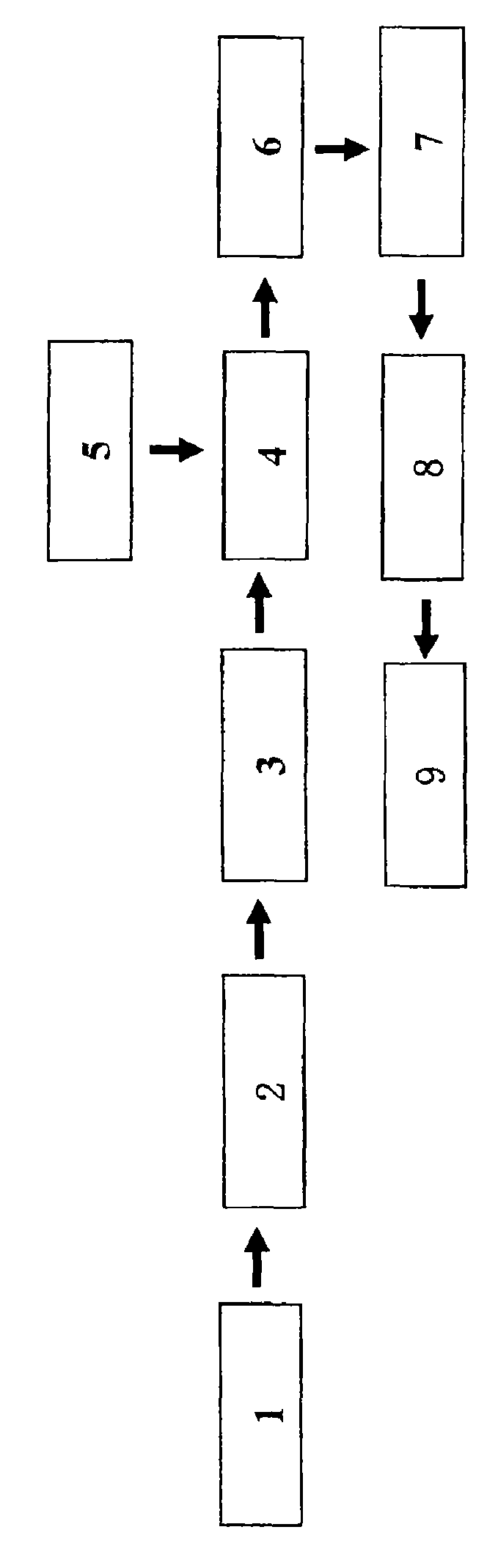

[0023] see figure 1 , is a schematic diagram of the preparation process and application process of the present invention.

[0024] The mycelia or / and the fungus residue raw material 1 are dehydrated, and the dehydration equipment 2 is a known equipment, such as a centrifugal dehydrator and a filter press dehydrator; in this example, a centrifugal dehydrator is used.

[0025] The dehydrated mycelium or / and bacterium slag 1 are dried, and the drying equipment 3 is a known equipment...

Embodiment 2

[0028] On the basis of Example 1, the mycelia or / and the fungus residue 1 are dehydrated, and the dehydration equipment 2 is a known equipment, such as a centrifugal dehydrator and a filter press dehydrator; this example adopts a centrifugal dehydrator.

[0029] The dehydrated mycelium or / and bacterium slag 1 are dried, and the drying equipment 3 is a known equipment. This example adopts a rotary drying furnace, and the heat of this rotary drying furnace utilizes a circulating fluidized bed coal-fired boiler to discharge The hot flue gas is used to dry the mycelium or / and the fungus residue 1 . Dehydration and drying to the moisture content of mycelium or / and bacterium slag 1 is less than or equal to 25% (percentage by weight), adds boiler fuel coal 5 and mixes, and the moisture content of the boiler biomass fuel that makes is less than or equal to 25% (percentage by weight) percentage). The amount of fuel coal added to the boiler is not strictly limited, and it only needs to...

Embodiment 3

[0031] The mycelia or / and fungal slag raw materials with a water content of 60% are added to boiler fuel coal and mixed to obtain boiler biomass fuel, wherein the amount of boiler fuel coal added is such that the water content of the boiler biomass fuel is less than or equal to 25%.

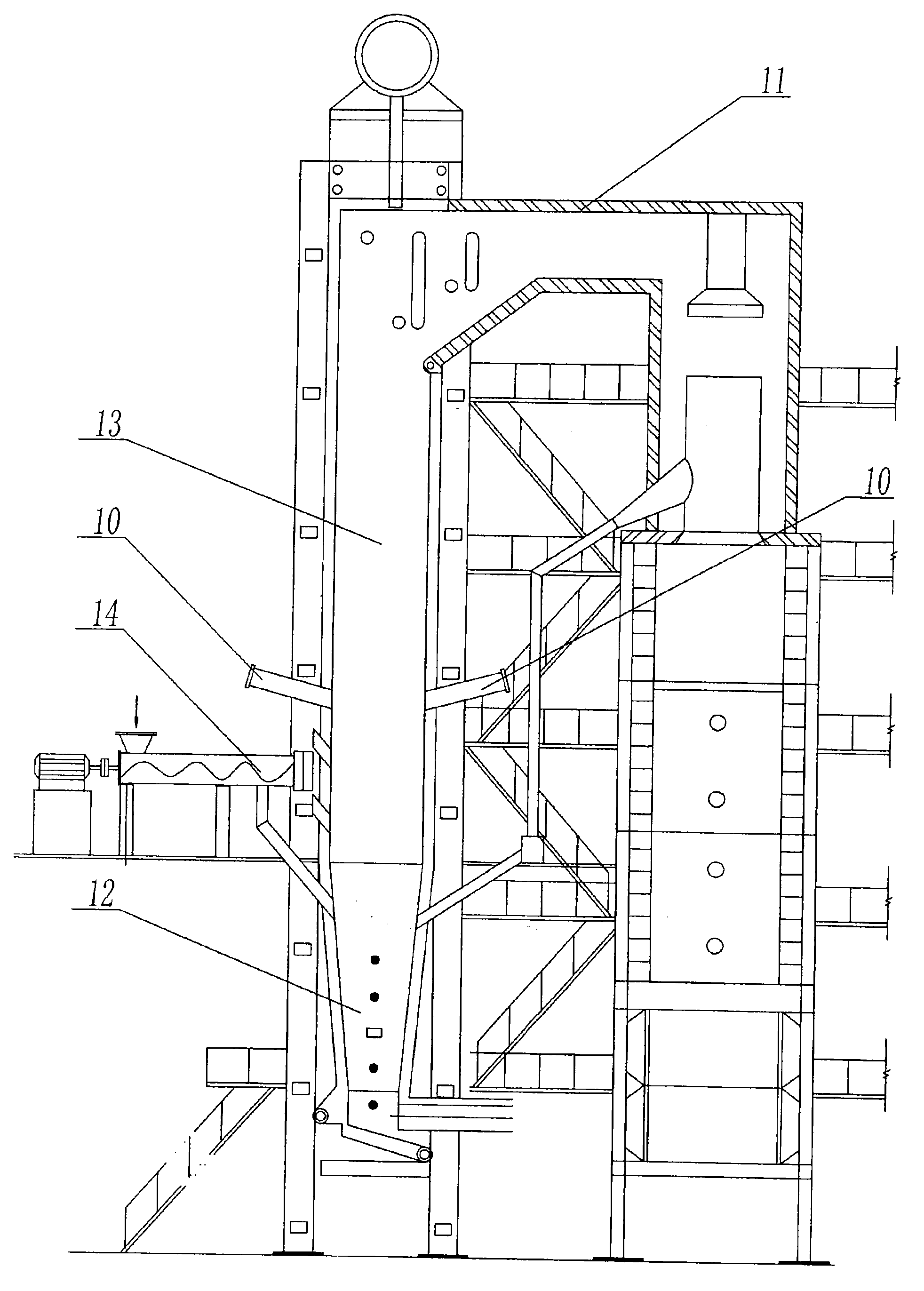

[0032] In order to further illustrate its application process of boiler biomass fuel prepared by the present invention, please combine figure 1 and figure 2 . figure 2 Shown is figure 1 The concrete example of the coal-fired boiler 8 in the present invention, the coal-fired boiler of the present invention is known equipment, can adopt chamber-fired boiler, circulating fluidized bed boiler, layer fired boiler etc., more ideally adopt circulating fluidized bed coal-fired boiler 11 .

[0033] The method of using the boiler biomass fuel 6 in the circulating fluidized bed coal-fired boiler 11 will be briefly described below. It should be noted that there is no strict limitation on the type of bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com