Oxidation ditch sewage treatment system for pre-biochemical oxidation treatment

A sewage treatment system and biochemical oxidation technology, applied in the field of comprehensive sewage treatment systems and sewage treatment systems, can solve the problems of low sewage concentration, unsuitable for high concentration sewage purification, etc., and achieve the effect of reducing the content of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

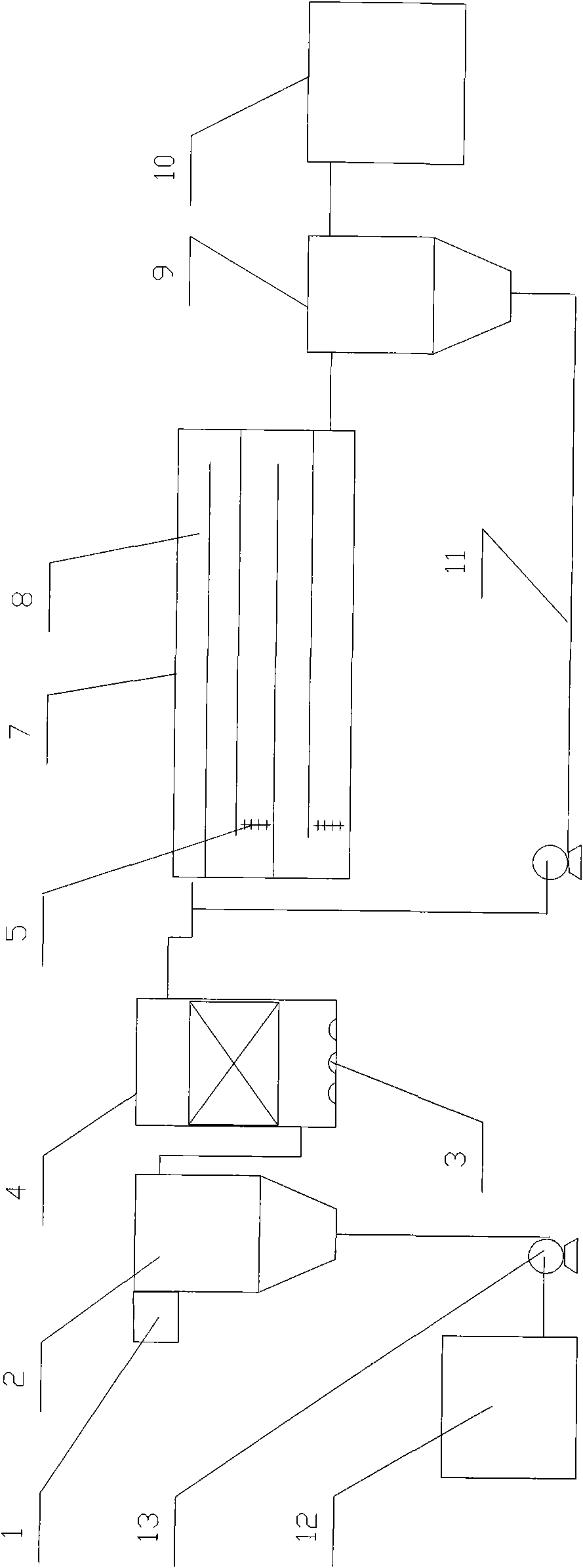

[0009] see figure 1 , The present invention provides an oxidation ditch sewage treatment system for pre-biochemical oxidation treatment, comprising a grid 1, a water collection sedimentation tank 2, a contact oxidation tank 4 and an oxidation ditch 7 connected in sequence.

[0010] The sewage first enters the water collection and sedimentation tank through the grille, and the water collection and primary sedimentation are combined into one, which can simplify the overall structure of the equipment and save investment.

[0011] The grille is provided at the inlet of the water collection and sedimentation tank.

[0012] The grid is preferably a mechanical grid, and is provided with a bulky material outlet, so that the bulky material in the water can be separated and processed separately, so as to avoid hindrance to the subsequent process.

[0013] The lower part of the water collection and sedimentation tank is in the shape of an inverted truncated cone, and the bottom is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com