Novel parallel composite yarns

A yarn and untwisted yarn technology, which is applied in the direction of yarn, textiles, papermaking, adhesives, etc., can solve the problems of large internal stress of untwisted fibers and skeleton yarns, and achieve the effect of good comfort and improved flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

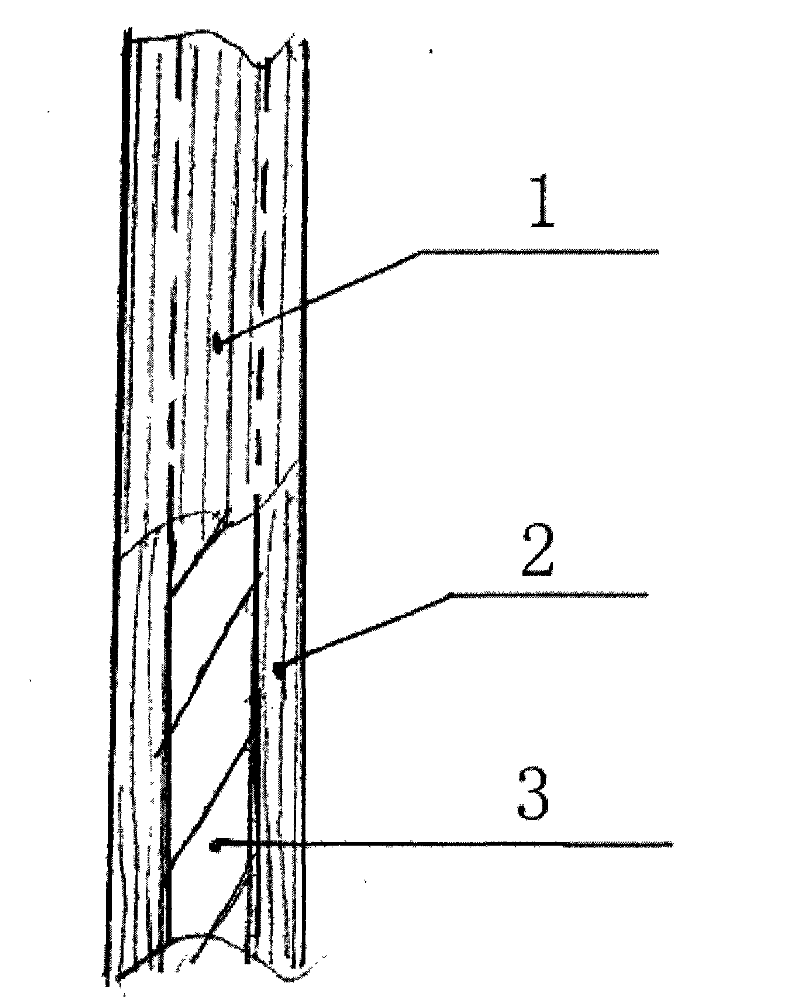

[0037] Embodiment 1: Novel ramie / polyester-cotton side-by-side composite woven fabric yarn

[0038] 1. Yarn count: 76 public counts × 2 single side-by-side composite yarns (see figure 1 Middle 5. Single side-by-side composite yarn)

[0039] 2. Raw material ratio: ramie (long spinning) 63%, polyester (short fiber) 24%, cotton 13%

[0040] 3. Process design:

[0041] (1) Quantitative roving (ramie): 4.00 g / 10 meters, feed 1 roving / each spinning position;

[0042] (2) Skeleton yarn count (polyester / cotton): 60 British count ring spinning single yarn, feeding 1 roving / each spinning position.

[0043] (3) Spinning draft ratio: 24 times

[0044] (4) Front roller speed: 150 m / min

[0045] (5) No twisting after yarn forming

Embodiment 2

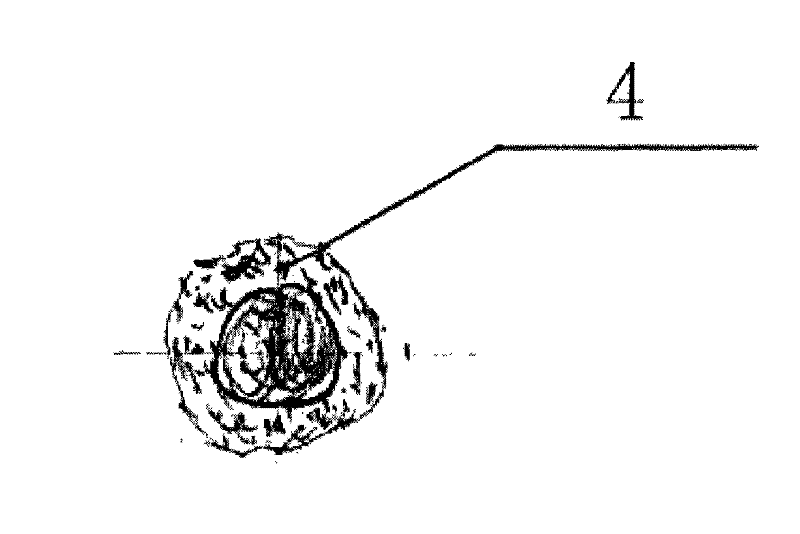

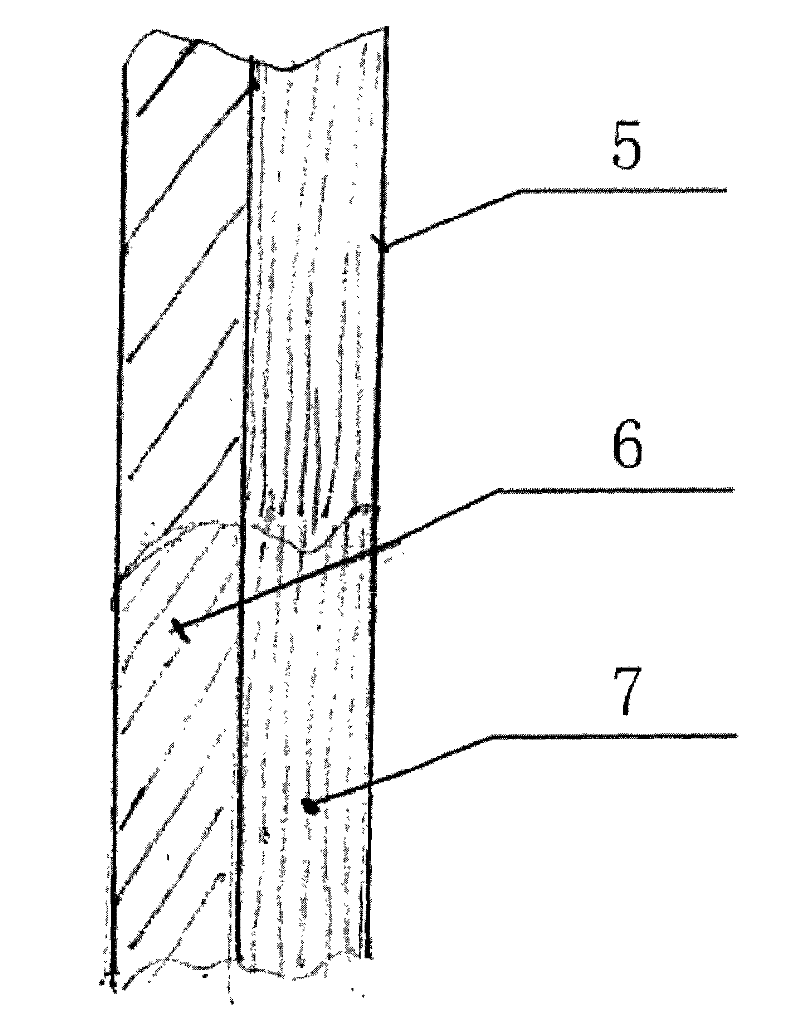

[0046] Embodiment 2: Novel modal / wool side-by-side composite large circular knitting machine fabric yarn

[0047] 1. Yarn count: 100 public counts x 2 single twisted parallel composite yarns (see figure 2 Middle 9. Single twisted parallel composite yarn)

[0048] 2. Raw material ratio: Modal 50%, worsted mercerized wool yarn 50%

[0049] 3. Process design:

[0050] (1) Roving weight (modal): 3.04g / 10m, feeding 1 roving / each spinning position

[0051] (2) Skeleton yarn count (pure wool): 100 public count ring spun single yarn, feed 1 skeleton yarn / each spinning position

[0052] (3) Spinning draft ratio: 31.25 times

[0053] (4) Front roller speed: 150 m / min

[0054] (5) Add S twist after yarn forming, the twist is 29 twists / 10cm

Embodiment 3

[0055] Embodiment 3: Novel silk / polyester side by side composite woven fabric yarn

[0056] 1. Yarn count: 170 public counts × 2 single twisted parallel composite yarns (see figure 2 Middle 9. Single twisted parallel composite yarn)

[0057] 2. Raw material ratio: silk 55%, polyester 45%

[0058] 3. Process design:

[0059] (1) Roving weight (modal): 2.03g / 10m, feed 1 roving / each spinning position

[0060] (2) Skeleton yarn fineness (polyester): 55dtex, polyester filament, plus Z twist 110 twist / 10cm

[0061] (3) Spinning draft ratio: 31.25 times

[0062] (4) Front roller speed: 150 m / min

[0063] (5) Add S twist after yarn forming, the twist is 38 twists / 10cm

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com