Semiconductor side pumping module

A side pumping and semiconductor technology, which is applied to laser components, the structure/shape of the active medium, electrical components, etc., can solve the problems of cylindrical lens loss of pump light, low absorption efficiency, and large energy loss, etc., to improve the beam Quality, improvement of absorption efficiency, and effect of reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

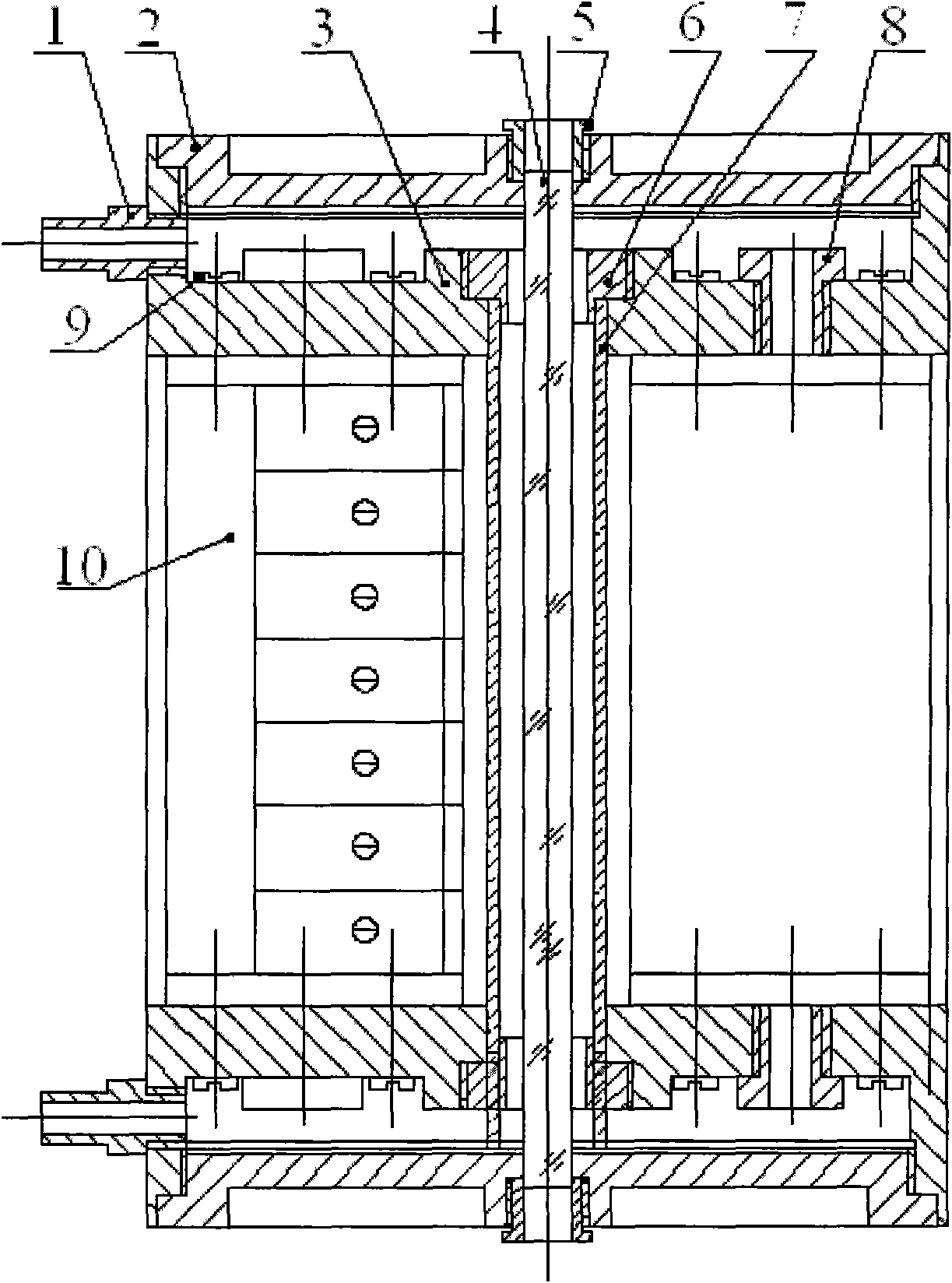

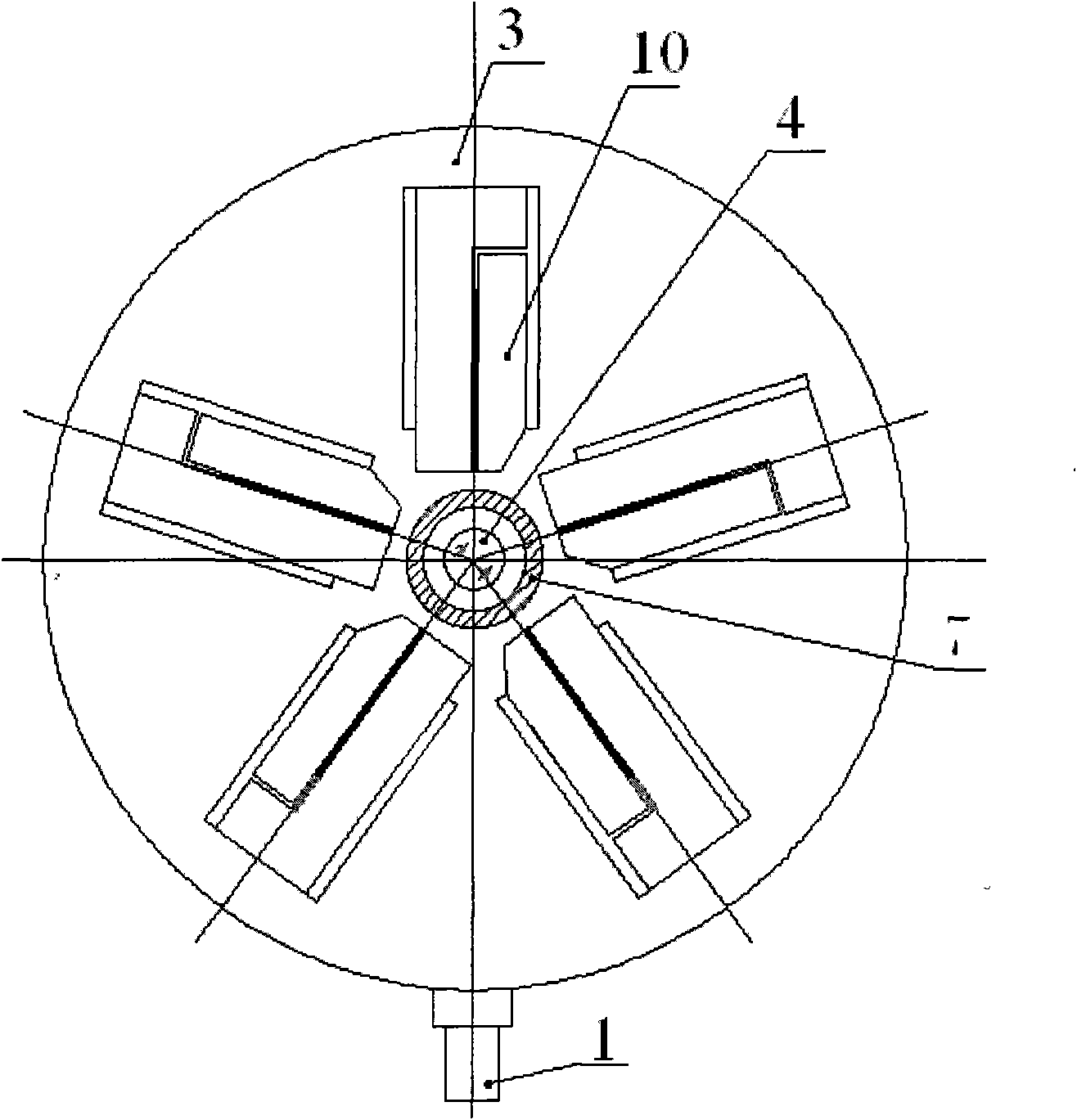

[0020] Example 1 as figure 1 and figure 2 As shown, a semiconductor side pump module of the present invention includes a water connector 1, an outer end cover 2, an inner end cover 3, a laser crystal 4, a gland 5, a retaining ring 6, a quartz tube 7, a flow guide tube 8, a fixed Composed of screws 9 and a semiconductor laser horizontal array 10;

[0021] The water joint 1 and the inner end cover 3 are connected by threads, and the water cooling channel in the water joint 1, retaining ring 6, quartz tube 7, guide tube 8 and semiconductor laser horizontal array 10 constitutes a cooling water circulation channel, located in a The two ends of the semi-conductor side pump module conduct the internal waste heat out through water circulation;

[0022] The inner end cover 3 is a hollow annular body, which is connected with the semiconductor laser horizontal array 10 by fixing screws 9 to realize fixing the semiconductor laser horizontal array 10, and is connected with the outer end...

Embodiment 2

[0031] Example 2 as figure 1 and figure 2 As shown, the number of semiconductor laser horizontal arrays 10 is three, which are evenly distributed around the quartz tube 7, and the others are the same as in Embodiment 1.

Embodiment 3

[0032] Example 3 as figure 1 and figure 2As shown, the number of semiconductor laser horizontal arrays 10 is 7, which are evenly distributed around the quartz tube 7, and the others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com