Method for manufacturing conductive pattern on flexible substrate and protective printing oil thereof

A conductive pattern and ink protection technology, which is applied to inks, chemical/electrolytic methods to remove conductive materials, household appliances, etc., can solve problems such as unsuitable printing of fine lines, complicated equipment, and expensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

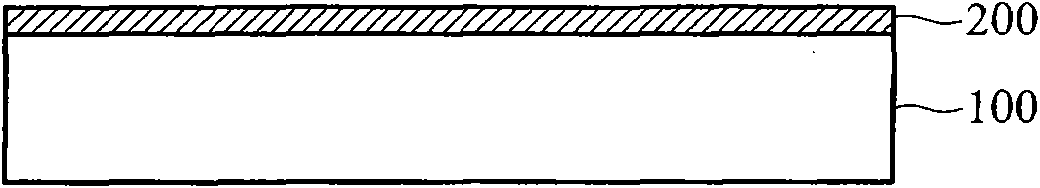

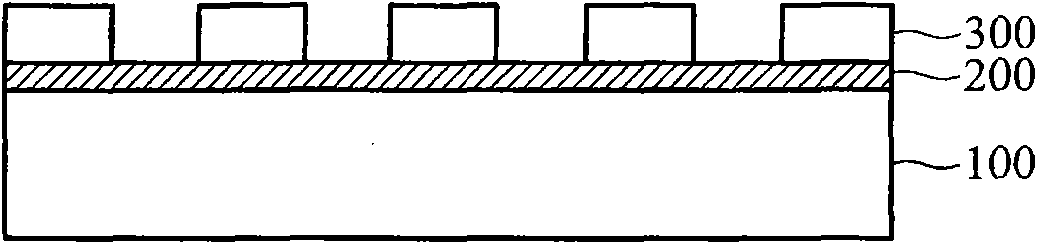

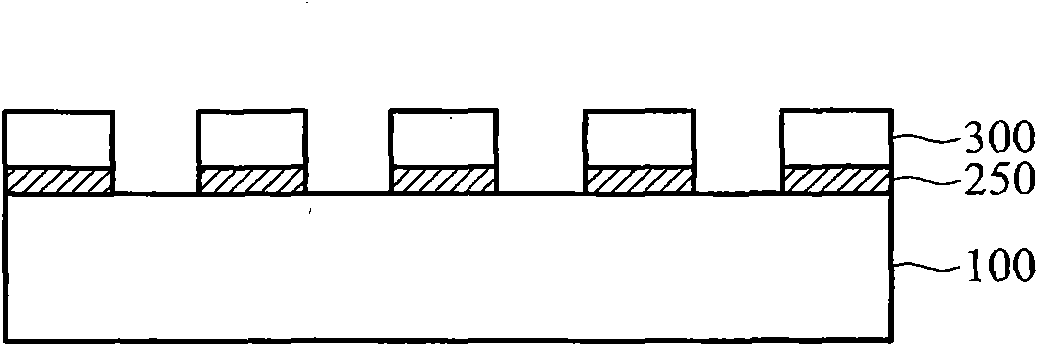

Method used

Image

Examples

Embodiment 1

[0031] [Example 1: Protecting Screen Printing Ink A]

[0032] First prepare the epoxy resin solution: 15 parts by weight of bisphenol A epoxy resin (BE-188; Changchun Company), 11.6 parts by weight of epoxy resin (BE325; Changchun Company), and 37.3 parts by weight of bisphenol A type containing -OH Base epoxy resin (BE500; Changchun Company) was dissolved in 126 parts by weight of propylene glycol monomethyl ether (Propylene glycol monomethyl ether; PGME) and mixed and stirred for reaction. The reaction temperature was 125°C and stirred for four hours under nitrogen. Begin to cool down to 80°C, then add 9.7 parts by weight of 4,4-diaminodiphenylsulfone (4,4-Diamino Diphenyl Sulfone; DDS) (Jingming Chemical Industry), and then react for 120 minutes, then continue to reduce the reaction temperature to Serve as epoxy resin solution at room temperature.

[0033] Preparation of protective ink: the epoxy resin solution (91.4 parts by weight) prepared above, anti-adhesion agent (LY...

Embodiment 2

[0036] [Example 2: Protecting Screen Printing Ink B]

[0037] Add 15 parts by weight of vinyl chloride-vinyl acetate-maleic acid ternary copolymer resin (VMCH) to 81.3 parts by weight of ethylene glycol butyl ether acetate (Ethylene Glycol Monobutyl Ethyl Acetate; EGMEA) and put it into a tank and stir to dissolve at 90°C It is a solution, and transferred into 0.2 parts by weight of thickener (BYK410; BYK company), 1.5 parts by weight of (BYK344; BYK company) leveling agent and 1 part by weight of colorant (Material Chemical Institute) is the protective ink B, solid content 16.4%.

[0038] Table 2. Composition of protective ink B

[0039] VMCH copolymer resin

Embodiment 3

[0040] [Example 3: Protecting screen printing ink C]

[0041] 1 part by weight of blue pigment is mixed into 20 parts by weight of thermoplastic polyurethane elastomer resin (Estane5715; thermoplastic polyurethane elastomer, TPU) and 78.4 parts by weight of diethylene glycol monomethyl ether acetate (Carbitol Acetate)) solvent, and Adding 0.6 parts by weight (BYK344; BYK Company) leveling agent is the protective screen printing ink C.

[0042] Table 3. Composition of protective screen printing ink C

[0043] Estane 5715

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com