Matrix-embedded compositions having organic acids and fatty acids

A technology of composition and fatty acid, which is applied in the direction of organic active ingredients, molding or processing of animal feed, medical preparations containing active ingredients, etc., and can solve problems such as protective coating defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] II. Preparation process of matrix-embedded composition

[0069] Another aspect of the invention relates to a process for the preparation of a matrix-embedded composition. Several suitable methods of preparing matrices comprising organic and fatty acids are available. In general, the methods of the present invention include heating a substrate, mixing the heated substrate with an organic acid and a fatty acid to form a solution, and curing the solution to form a matrix-embedded composition. Any of the organic acids, fatty acids and substrates described above may be used. In some contexts, a lipid matrix (eg, a source of fat) is used.

[0070] By way of non-limiting example, the preparation process may be initiated by heating the fat source in a container for a time sufficient to completely liquefy the fat source. The fat source is heated to a temperature of about 50-80°C under continuous agitation. The container can be any suitable container that includes heating and...

Embodiment 1

[0101] Embodiment 1: composition preparation method

[0102] A series of storage tanks containing pellets of different organic acids were placed and connected to the main mixing tank. Heat vegetable oil in a blender until liquefied. Then, solid material (acid) is added to start the mixing process. After the mixture has reached the desired pressure and temperature it is pumped (in a continuous flow) into the top of the spray tower. The mixture is passed through nozzles that spray the mixture through a column of cooling air, causing the mixture to crystallize into fat globules. These fat globules fall to the bottom of the spray tower due to gravity. The sphere will cool while falling. At the bottom of the spray tower are three layers of independent screens of different sizes. The screen separates spheres based on particle size; only intermediate particle size product is retained. The other two particle sizes are sent back to the preparation process again to avoid wasting m...

Embodiment 2

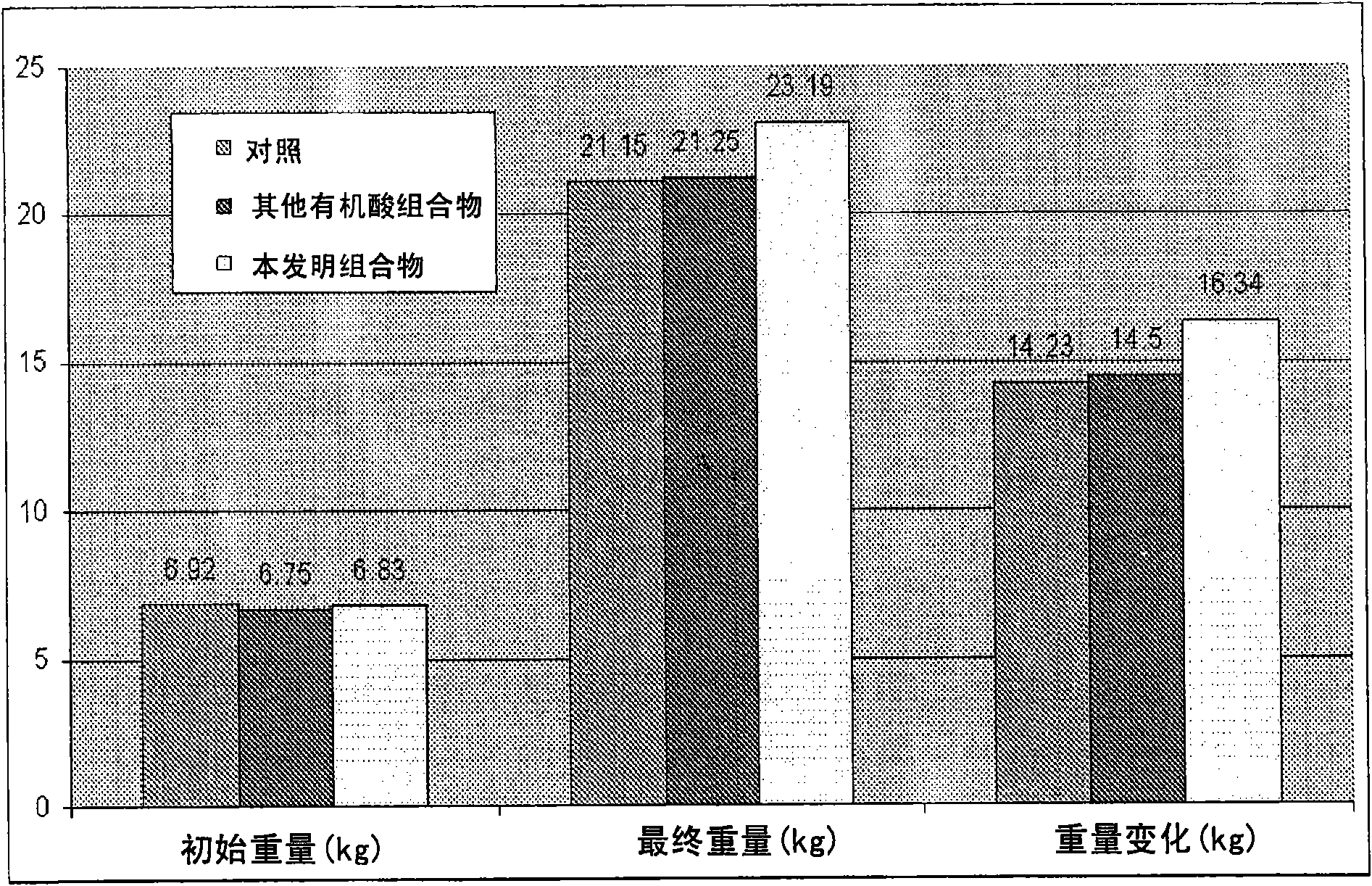

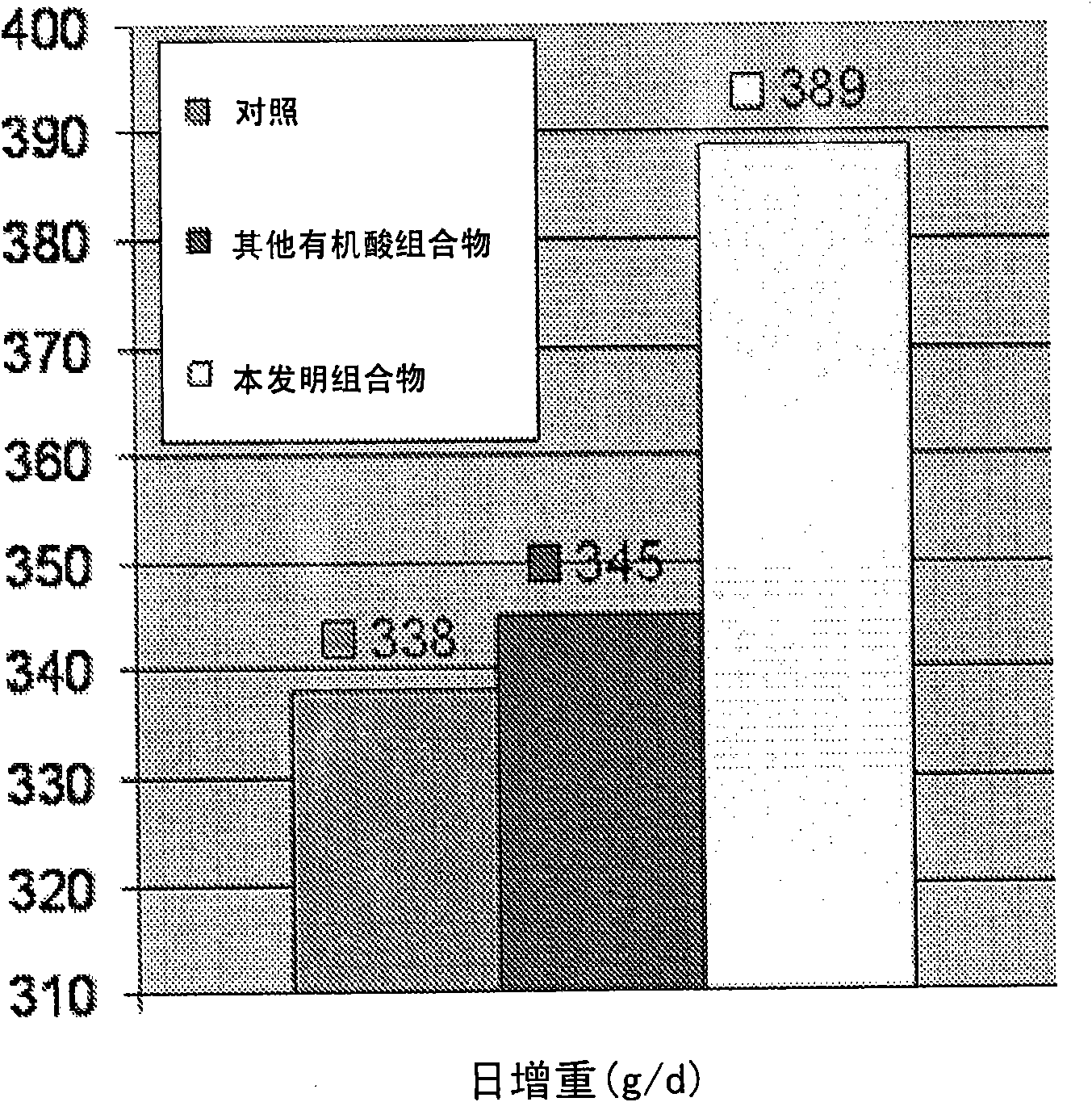

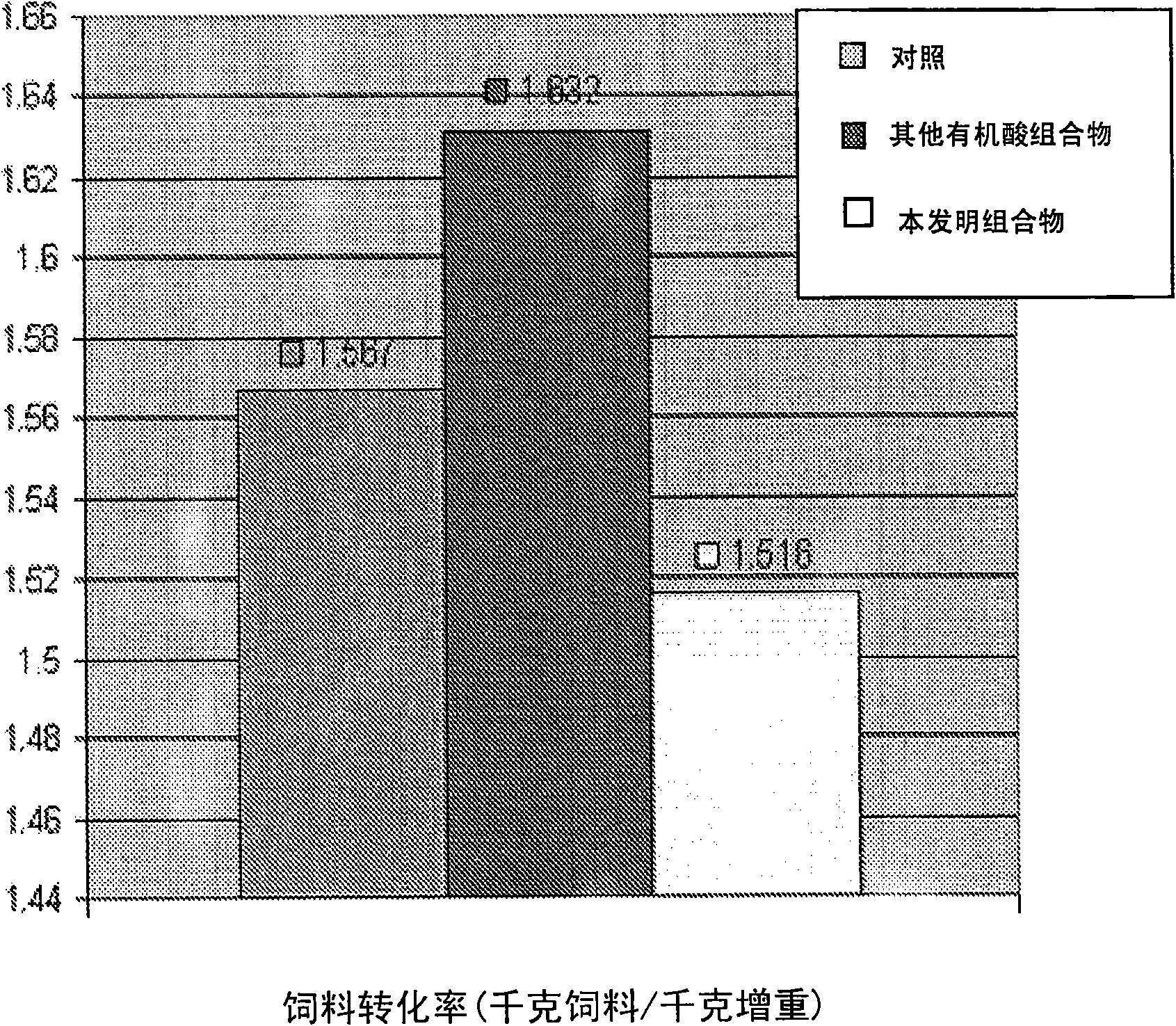

[0103] Example 2: Efficacy of the composition

[0104] Compositions of the invention were administered to weaned piglets as part of a control program trial. The procedure was designed to test whether pigs maintained high health status and daily weight gain when receiving moderate feed. The experiments were carried out at the Research and Demonstration Station of St. Wendelin, Bingen Institute, Germany. 104 male / female crossbred piglets were reared for 21 days with one of three different treatments. A total of 8 groups, 13 piglets in each group. Piglets were given 0.3% (dry matter) of the embedded composition of the invention, another organic acid composition or a control diet. The embedding composition of the present invention contains calcium formate, benzoic acid, sorbic acid, caprylic acid, capric acid and a base comprising palm oil. The organic acid composition contains calcium formate, benzoic acid, sorbic acid and a base comprising palm oil. The control diet contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com