Electron-grade high purity hydrofluoric acid preparation method

A hydrofluoric acid, electronic-grade technology, applied in fluorine/hydrogen fluoride and other directions, can solve the problems of difficult separation of arsenic trifluoride impurities and difficulty in ensuring product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

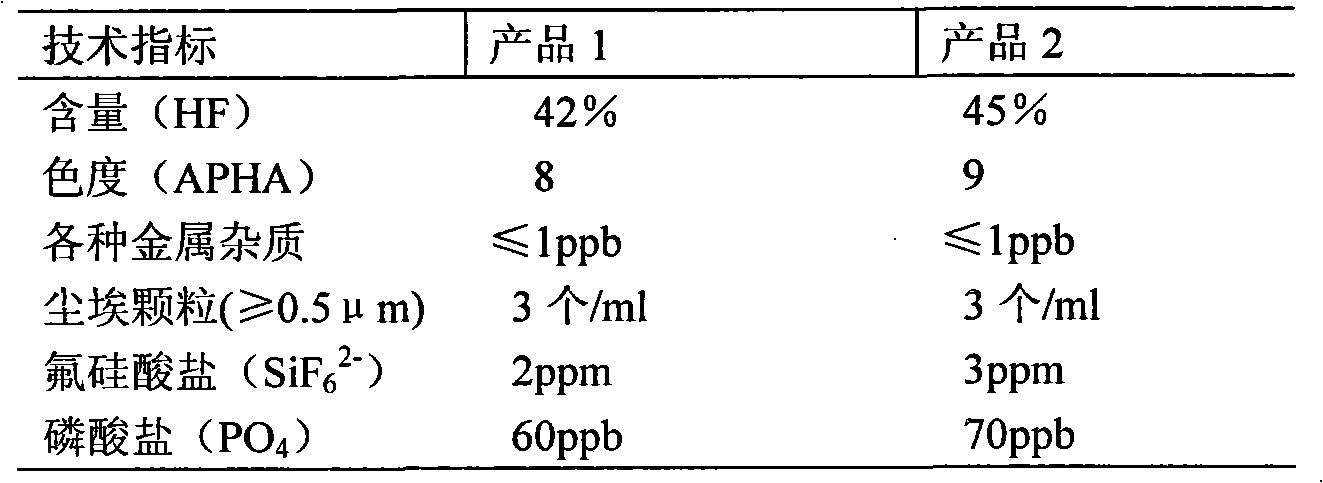

[0022] Place 500kg of liquid anhydrous hydrogen fluoride in a high-position stirring tank, and add KMnO with a mass percent concentration of 3%. 4 Aqueous solution, the addition amount is 10kg; at the same time, add 10kg of NaOH aqueous solution with a concentration of 3% by mass, fully stir and let it stand for 0.5 hours, then put it into a rectification tower, the temperature at the bottom of the tower is 60°C, and the rectification temperature is 30°C Use ultrapure water to rectify and purify hydrogen fluoride gas to absorb again, make hydrofluoric acid semi-finished product, its concentration 42% (w / w), weight 965kg; Bed multi-cycle ion exchange, ultrafiltration membrane separation, to obtain electronic grade high-purity hydrofluoric acid product 1, weighing 948kg, the technical indicators are shown in Table 1.

Embodiment 2

[0024] Place 300kg of liquid anhydrous hydrogen fluoride in a high-position stirring tank, and add KMnO with a mass percentage concentration of 3%. 4 Aqueous solution, the addition amount is 6kg; at the same time, add 6kg of NaOH aqueous solution with a concentration of 3% by mass, fully stir and let it stand for 1 hour, then put it into the rectification tower, the temperature at the bottom of the tower is 65°C, and the rectification temperature is 29°C; Use ultra-pure water to absorb the hydrogen fluoride gas obtained by rectification and purification to make a semi-finished product of hydrofluoric acid, with a concentration of 45% (w / w) and a weight of 515kg; the semi-finished product of hydrofluoric acid is made of polymer chelating adsorbent, mixed bed Multi-cycle ion exchange, ultrafiltration membrane separation, to obtain electronic grade high-purity hydrofluoric acid product 2, weighing 506kg, the technical indicators are shown in Table 1.

[0025] Table 1 Measurement ...

Embodiment 3

[0028] Place 500kg of liquid anhydrous hydrogen fluoride in a high-position stirring tank, and add KMnO with a mass percent concentration of 4%. 4 Aqueous solution, the addition amount is 20kg; at the same time, add 20kg of NaOH aqueous solution with a mass percentage concentration of 5%, fully stir and let it stand for 1 hour, then put it into a rectification tower, the temperature at the bottom of the tower is 65°C, and the rectification temperature is 19°C; Use ultra-pure water to absorb the hydrogen fluoride gas obtained by rectification and purification to make a semi-finished product of hydrofluoric acid, with a concentration of 45% (w / w) and a weight of 965kg; the semi-finished product of hydrofluoric acid is made of polymer chelating adsorbent and mixed bed Multi-cycle ion exchange and ultrafiltration membrane separation to obtain electronic grade high-purity hydrofluoric acid with a weight of 940kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com