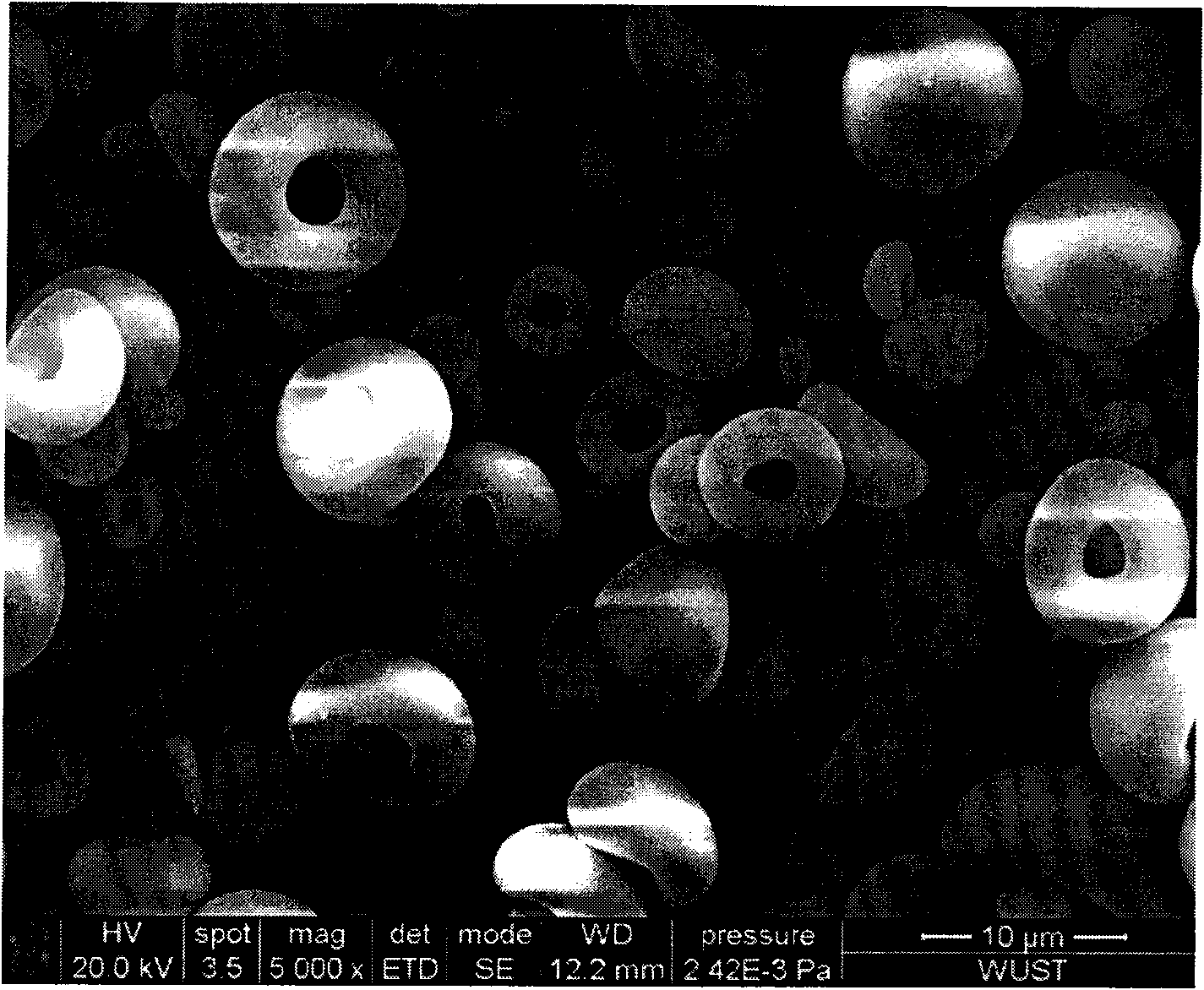

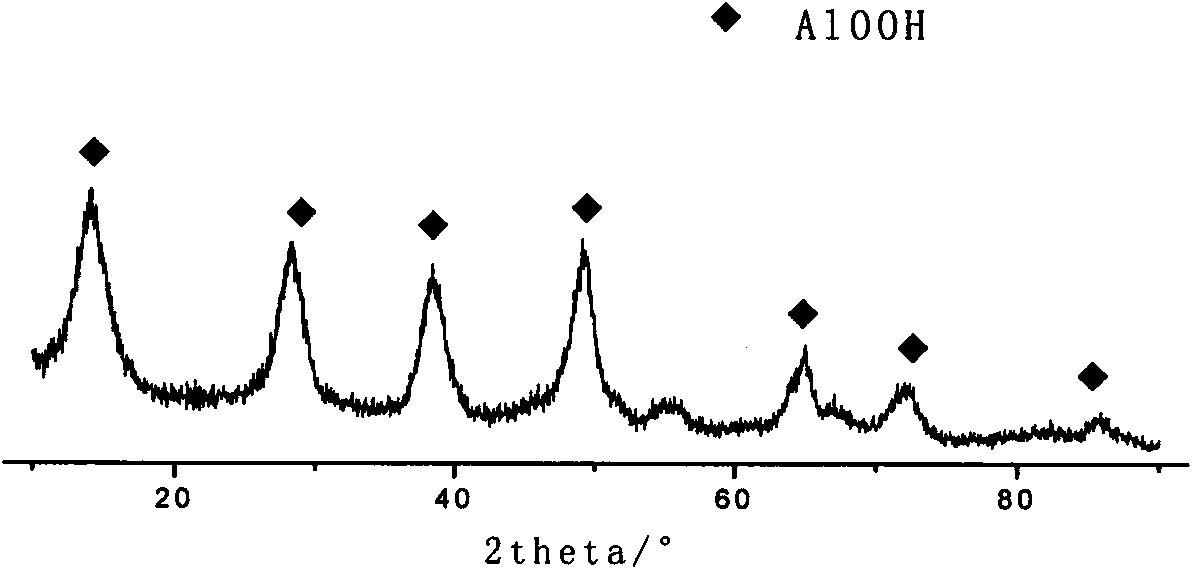

Seashell boehmite powder and preparation method thereof

A boehmite powder and shell-like technology, which is applied to the field of shell-like boehmite powder and its preparation, can solve the problems of complex equipment, high reaction temperature and high operation requirements, and achieves narrow particle size distribution range, simple preparation process, The effect of low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] A preparation method of shell-shaped boehmite powder: firstly prepare 0.5-1mol / L AlCl 3 solution and 1-1.5mol / L ammonia solution for use; then add surfactant to AlCl 3 In the solution, the amount of surfactant added is AlCl 3 AlCl in solution 3 0.1 to 0.2% of the amount of the substance, stirred for 0.5 to 1 hour; then at 60 to 80 ° C and stirring conditions, the AlCl after adding the surfactant 3 The solution is added into the ammonia solution at a rate of 10-15ml / min, the pH value is controlled to be 7.5-8, and the stirring is continued for 0.5-1.5 hours to obtain the precursor boehmite precipitate.

[0016] Then the boehmite precipitate is filtered with pure water for 2 to 3 times to obtain a filter cake, and the molar ratio of boehmite and pure water is 1: (9 to 19) to disperse the filter cake in pure water; Stir at a speed of 1 / min for 0.5 to 1 hour to obtain a boehmite suspension; finally, dry the suspension to obtain a boehmite powder.

[0017] In this embodi...

Embodiment 2

[0019] A method for preparing conchoidal boehmite powder. Surfactant is polyethylene glycol 2000, and all the other are with embodiment 1.

Embodiment 3

[0021] A method for preparing conchoidal boehmite powder. The surfactant is a mixed solution of polyethylene glycol 400 and polyethylene glycol 2000, and the rest are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com