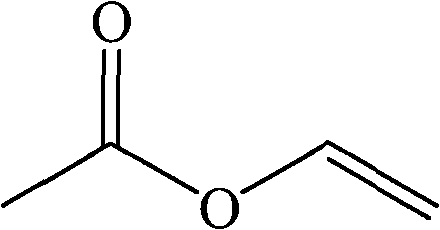

Polyvinyl acetate mixed suspended liquid and preparation method and application thereof

A technology of polyvinyl acetate and vinyl acetate, which is applied in the field of polyvinyl acetate suspension and its preparation and application, can solve the problems of poor stability and high vinyl acetate monomer, and achieve good suspension and settlement performance , Low requirements for production equipment, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043]

[0044]

[0045] Add the stabilizer and water into the reactor which is pre-filled with nitrogen and equipped with stirrer, reflux condenser and thermometer, and dissolve it. Add 20% of the vinyl acetate, start stirring, heat the thermostat, and control the reaction temperature at 70°C. Take the initiator, add 1 / 3 of its mass into the reactor, add the remaining 80% of vinyl acetate and the remaining 2 / 3 of the initiator dropwise after starting the reaction, and finish the drop within 3 hours. Continue to react for about 3 hours until there is no reflux. After the material was cooled to 50° C., 1% sodium bicarbonate solution was added to adjust the pH of the material to 5. Obtain a white opaque emulsion, adjust the solid content of the material to about 30% with purified water, and obtain a medicinal polyvinyl acetate suspension.

[0046] The content of each component of the polyvinyl acetate suspension is as follows:

[0047]

Embodiment 2

[0049]

[0050]

[0051] After adding stabilizer and water into a reactor filled with nitrogen in advance and equipped with a stirrer, reflux condenser and thermometer, dissolve it. Add 40% of the vinyl acetate, start stirring, heat the thermostat, and control the reaction temperature at 65°C. Take the initiator, add 2 / 5 of its mass into the reactor, add the remaining 60% of vinyl acetate and the remaining 3 / 5 of the initiator dropwise after starting the reaction, and finish dropping within 3 hours. Continue to react for about 3 hours until there is no reflux. After the material was cooled to 50° C., 1% sodium bicarbonate solution was added to adjust the pH of the material to 4. Obtain a white opaque emulsion, adjust the solid content of the material to about 30% with purified water, and obtain a medicinal polyvinyl acetate suspension.

[0052] The content of each component of the polyvinyl acetate suspension is as follows:

[0053]

Embodiment 3

[0055]

[0056] After adding stabilizer and water into a reactor filled with nitrogen in advance and equipped with a stirrer, reflux condenser and thermometer, dissolve it. Add 28% of the vinyl acetate, start stirring, heat the thermostat, and control the reaction temperature at 75°C. Take the initiator, add 1 / 3 of its mass into the reactor, add the remaining 72% of vinyl acetate and the remaining 2 / 3 of the initiator dropwise after starting the reaction, and finish the drop within 3 hours. Continue to react for about 3 hours until there is no reflux. After the material was cooled to 50° C., 1% sodium bicarbonate solution was added to adjust the pH of the material to 6. Obtain a white opaque emulsion, adjust the solid content of the material to about 30% with purified water, and obtain a medicinal polyvinyl acetate suspension.

[0057] The content of each component of the polyvinyl acetate suspension is as follows:

[0058]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com