Plasma etching method and plasma etching apparatus

A technology of plasma etching and processing method, which is applied in the direction of plasma, electrical components, discharge tubes, etc., and can solve problems such as poor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

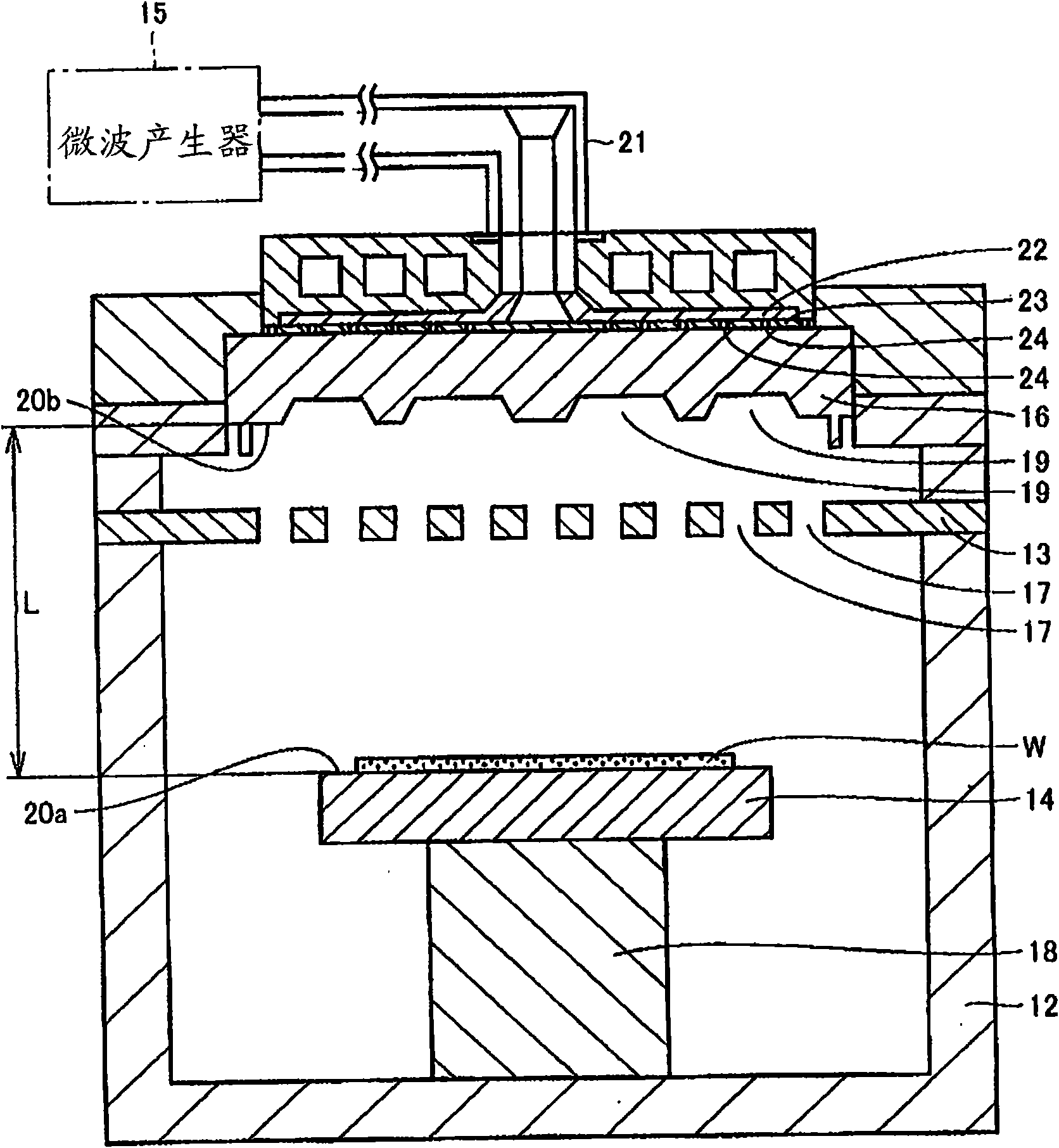

[0045] figure 1 It is a schematic sectional view showing main parts of a plasma etching processing apparatus according to an embodiment of the present invention. In addition, in the following drawings, the top in the sheet is regarded as the top.

[0046] refer to figure 1 , the plasma etching processing device 11 includes a processing container 12, a gas shower head 13, a holding table 14, a microwave generator 15, a dielectric plate 16, and a control unit (not shown); W performs plasma etching process; above-mentioned gas shower head 13 has a plurality of opening holes 17, as the reactive gas supply part that plasma etching process is supplied to processing container 12 with reactive gas; The bottom surface of the processing container 12 is provided on a support portion 18 extending upward, and the semiconductor substrate W is held on the holding table 14; the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com