Method for preparing chemical aluminum oxide by andalusite mine

A technology of andalusite and alumina, which is applied in the field of chemical alumina preparation, can solve the problems of complex process and high production cost, and achieve the effect of simple process, low production cost and good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

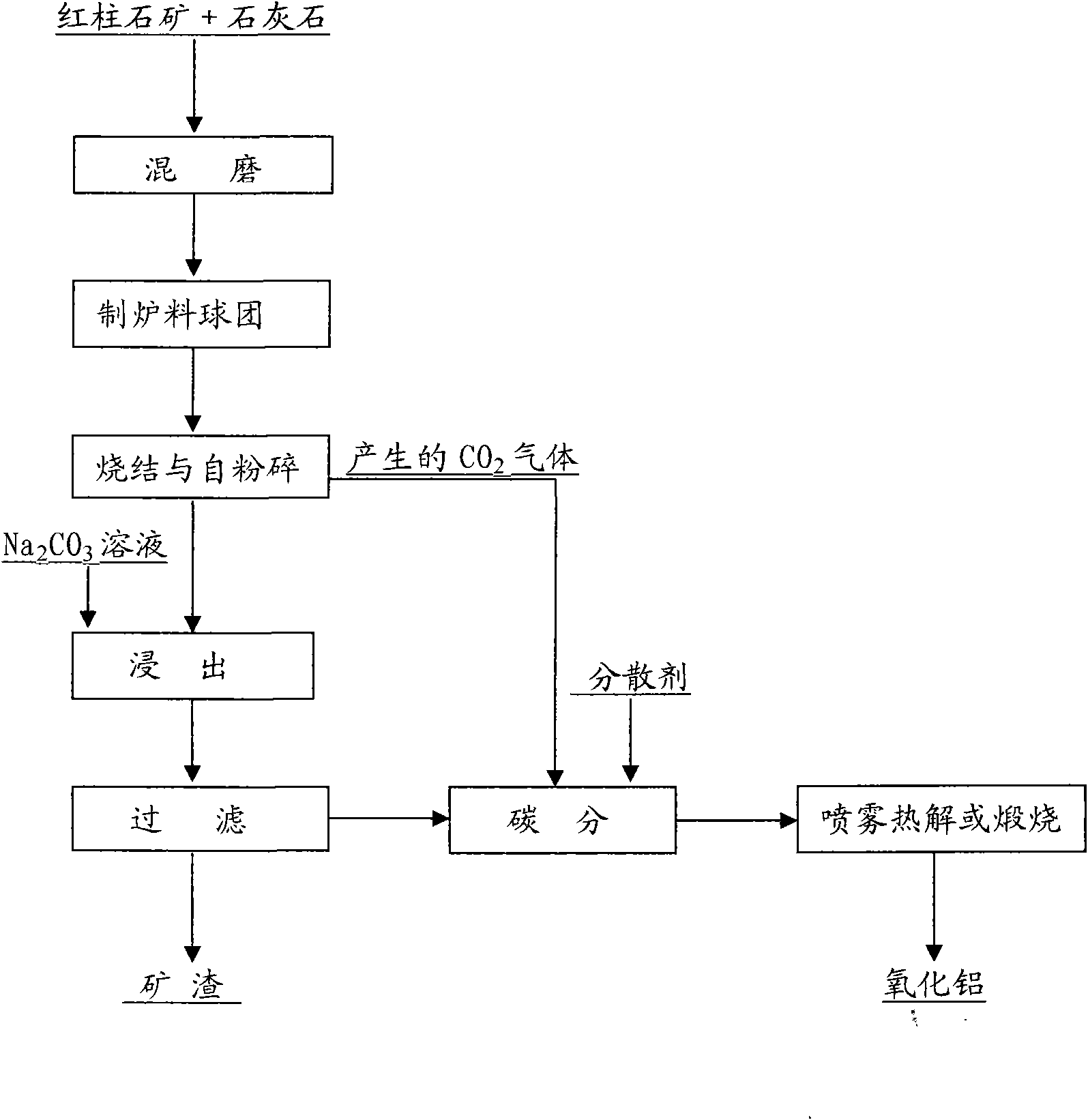

Method used

Image

Examples

Embodiment 1

[0031] The first step: batching, mixing and grinding, making furnace charge pellets

[0032] Mixing 86 parts by weight of andalusite and 114 parts by weight of limestone, crushing and pulverizing, grinding into a powder with a particle size of 75-120 microns, and pressing the powder into pellets;

[0033] The second step: sintering and self-crushing

[0034] Put the prepared charge pellets into the sintering furnace, roast at 1300°C for 60 minutes, and then cool to 50°C to obtain andalusite self-grinding material;

[0035] The third step: leaching, filtering

[0036] Put the self-grinding material into the leaching tank and add Na at a concentration of 8%. 2 CO 3 solution and stir to mix, since the pulverized material and Na 2 CO 3 The weight ratio of the solution is 1:2.8, heating the mixed mineral material to 85°C, mechanically stirring for 60 minutes, and the stirring speed is 1100r / min, and then vacuum filtering the mixed mineral material to remove the slag to obtain ...

Embodiment 2

[0045] The first step: batching, mixing and grinding, making furnace charge pellets

[0046] After mixing 90 parts by weight of andalusite ore and 110 parts by weight of limestone, crushing and pulverizing, grinding the powder into a powder with a particle size of 75-120 microns, and pressing the powder into furnace charge pellets;

[0047] The second step: sintering and self-crushing

[0048] Put the prepared charge pellets into the sintering furnace, roast at 1350°C for 50 minutes, and then cool to 60°C to obtain andalusite self-grinding material;

[0049] The third step: leaching, filtering

[0050]Put the self-grinding material into the leaching tank, and add Na with a concentration of 8.5% 2 CO 3 solution and stir to mix, since the pulverized material and Na 2 CO 3 The weight ratio of the solution is 1:2.5, heating the mixed mineral material to 90°C, mechanically stirring for 50 minutes, and the stirring speed is 1200r / min, and then vacuum filtering the mixed mineral...

Embodiment 3

[0059] The first step: batching, mixing and grinding, making furnace charge pellets

[0060] After mixing 80 parts by weight of andalusite ore and 120 parts by weight of an activator, crushing and grinding into a powder with a particle size of 75-120 microns, and pressing the powder into pellets;

[0061] The second step: sintering and self-crushing

[0062] Put the prepared charge pellets into the sintering furnace, roast at 1200°C for 60 minutes, and then cool to 40°C to obtain andalusite self-grinding material;

[0063] The third step: leaching, filtering

[0064] Put the self-grinding material into the leaching tank, and add Na with a concentration of 7.5% 2 CO 3 solution and stir to mix, since the pulverized material and Na 2 CO 3 The weight ratio of the solution is 1:3, heating the mixed mineral material to 80°C, mechanically stirring for 70 minutes, and the stirring speed is 1000r / min, and then vacuum filtering the mixed mineral material to remove the slag to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Graininess | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com