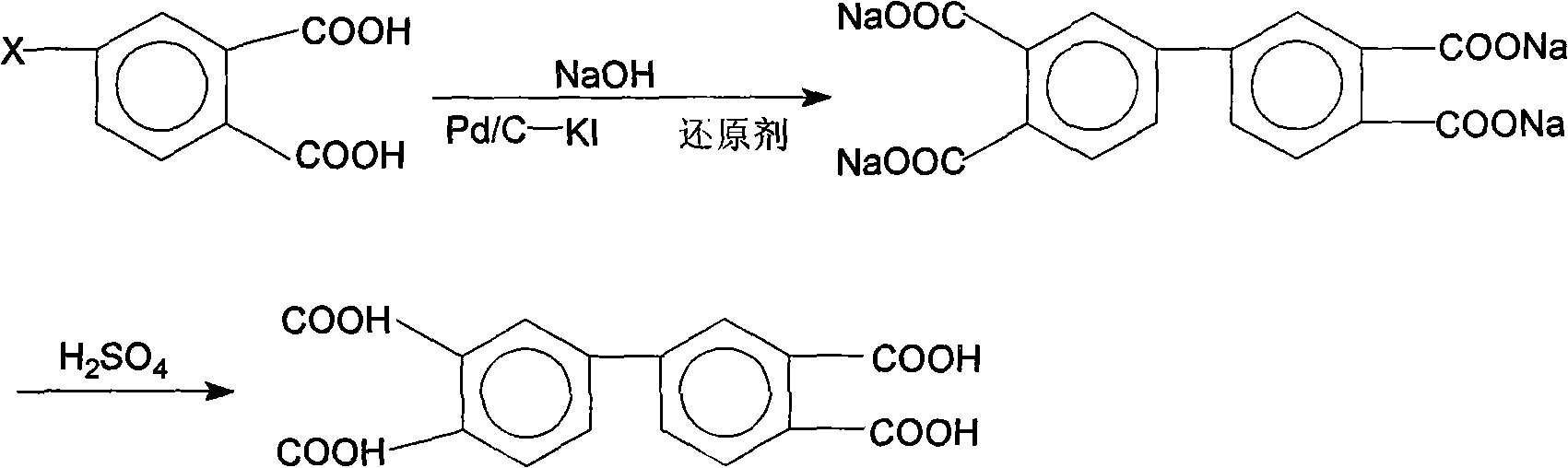

Preparation method of 3,3',4,4'-tetra carboxylic acid biphenyl

A technology of biphenyltetracarboxylic acid and phthalic acid, applied in 4 fields, can solve the problems of low yield, poor production efficiency and economic benefit, and high cost, and achieves high yield, high production efficiency and economic benefit, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Add 18g (0.45mol) of sodium hydroxide and 200ml of water to a four-necked reaction flask equipped with a dropping funnel, a thermometer, and stirring, heat up to 80°C, and after dissolving and transparent, add 15g (0.075mol) of 4-chloro-o- Phthalic acid, add 0.3g of the above-mentioned carbon catalyst, heat up to 90°C, add 3g of methanol dropwise, and the dropwise addition time is 4 hours. After the dropwise addition, keep the temperature for 3 hours, filter, and add the mother liquor dropwise to 10% sulfuric acid solution to obtain White crystals were filtered while hot and washed with water to obtain crude biphenyl tetracarboxylic acid.

[0026] Put the crude biphenyltetracarboxylic acid in 10 times purified water, boil it in water at 100°C for 5 hours, cool down, wash with water, and dry to obtain 10.1 g of biphenyltetracarboxylic acid with a measured yield of 82%, a purity of 99.7%, and a melting point of 298-300°C.

Embodiment 2

[0028] Add 14g (0.25mol) of potassium hydroxide and 250ml of water to a four-necked reaction flask equipped with a dropping funnel, a thermometer and stirring, and raise the temperature to 80°C. After dissolving and becoming transparent, add 12.3g of 4-bromophthalic acid in portions (0.05mol), add 0.1g of the above-mentioned catalyst, heat up to 95°C, add 5g glycerin aqueous solution dropwise, and the dropwise addition time is 2-5 hours. , white crystals were obtained, filtered while hot, and washed with water to obtain crude biphenyltetracarboxylic acid.

[0029] The crude biphenyltetracarboxylic acid was placed in 8 times purified water, boiled at 100°C for 4 hours, filtered, washed with water, and dried to obtain 7.4g of biphenyltetracarboxylic acid with a measured yield of 89.7%, a purity of 99.6%, and a melting point of 297-299°C.

Embodiment 3

[0031] Add 14g (0.25mol) of potassium hydroxide and 220ml of water to a four-necked reaction flask equipped with a dropping funnel, a thermometer and stirring, raise the temperature to 80°C, and after it dissolves transparently, add 11.7g of 4-iodophthalic acid in portions (0.04mol), add 0.1g of the above catalyst, raise the temperature to 95°C, add dropwise 1g of methanol solution, the dropwise addition time is 2-5 hours, after the dropwise addition, keep warm for 5 hours, filter, and add the mother liquor dropwise to 10% sulfuric acid solution , white crystals were obtained, filtered while hot, and washed with water to obtain crude biphenyltetracarboxylic acid.

[0032] The crude biphenyltetracarboxylic acid was placed in 8 times purified water, boiled at 100°C for 3 hours, filtered, washed with water, and dried to obtain 5.95g of biphenyltetracarboxylic acid with a measured yield of 90%, a purity of 99.5%, and a melting point of 297-299°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com