Computer cleaning rubber and preparation method thereof

A technology for cleaning glue and computer, applied in the direction of adhesives, adhesive additives, non-polymer adhesive additives, etc., can solve the problems of computer system damage, human harm, residual large dust and fine debris, etc., to achieve stable product quality, The effect of easy control of conditions and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1: a kind of computer cleaning gel provided by the present embodiment, by weight percentage, comprises following component (unit is g): phthalic acid diester 4.0%; Calcium carbonate 16%; Stearic acid 0.20%; 12% talcum powder, 8% butyl rubber; 0.8% ethylene butylene; 1.4% white carbon black; 5% softening oil; 2.5% surfactants containing aliphatic hydrocarbons.

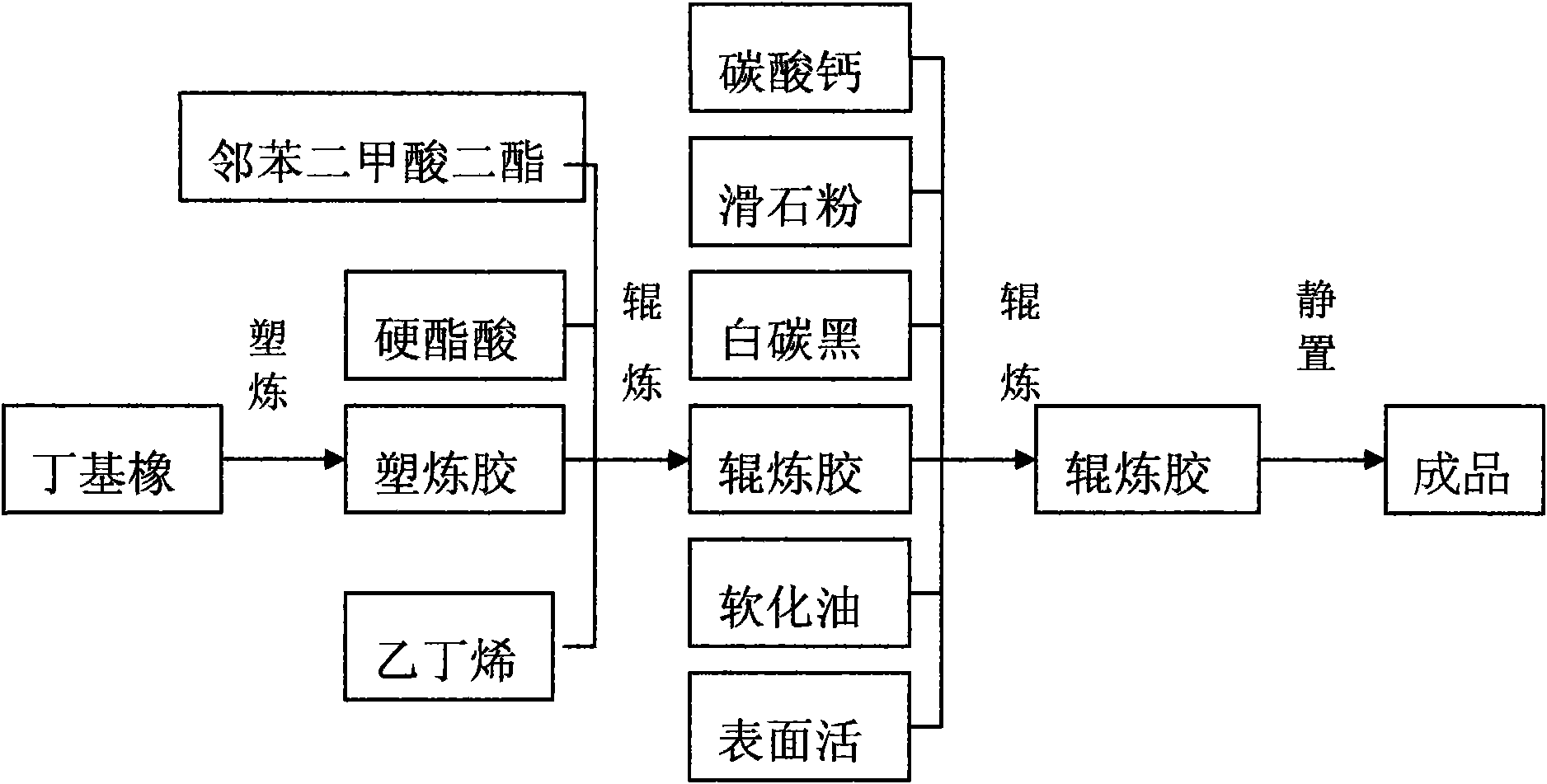

[0025] The preparation method of aforementioned computer cleaning glue, it comprises the steps:

[0026] (1) Adjust the rubber mill to the thinnest scale, turn on the cooling water, put in butyl rubber, and then turn on the machine for mastication to obtain masticated rubber, take out the masticated rubber, weigh and divide it, divide it into several parts of masticated rubber, and inspect Intermediate products, if qualified, go to the next step, and if unqualified, continue to masticate until qualified;

[0027] (2) take described plasticate rubber, phthalic acid diester, stearic acid and ethylene bu...

Embodiment 2

[0034] Embodiment 2: The computer cleaning glue provided in this embodiment and its preparation method, its basic technical scheme is the same as that of Example 1, the difference is that the computer cleaning glue includes the following components in parts by weight: phthalic acid 3.5% of diester; 18% of calcium carbonate; 0.15% of stearic acid; 14% of talc; 10% of butyl rubber; 0.6% of ethyl butyl; 1.8% of white carbon black; 3.5%.

Embodiment 3

[0035] Embodiment 3: the computer cleaning glue provided in this embodiment and its preparation method, its basic technical scheme is identical with embodiment 1, and its difference is, this computer cleaning glue comprises the component of following weight ratio: phthalic acid Diester 5.0%; Calcium Carbonate 14%; Stearic Acid 0.4%; Talc 8%; Butyl Rubber 7%; Ethylene Butene 0.9%; White Carbon Black 1.0%; Agent 4.5%.

[0036] The computer cleaning glue provided by the present invention can effectively remove dust and stains on the surface and gaps of computers and peripheral equipment, without scratching the surfaces of computers and other objects to be cleaned, without leaving residues, especially without moisture, and without cleaning. It will cause a short circuit in electronic circuits or components; after using a surface, rub the dirty surface into the interior of the colloid, and the new clean surface can be used again.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com