Silicon slice platform multi-platform exchange system adopting magnetic levitation planar motor

A planar motor and exchange system technology, applied in the direction of magnetic attraction or thrust holding device, electrical components, photo-plate making process exposure device, etc., can solve the problem of limiting the movement positioning accuracy of the silicon wafer stage, the large size of the silicon wafer stage system, Increase the burden of the underlying linear motor and other issues to achieve the effects of reducing processing costs, increasing speed, and avoiding vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific structure, mechanism and working process of the present invention will be further described below in conjunction with the accompanying drawings.

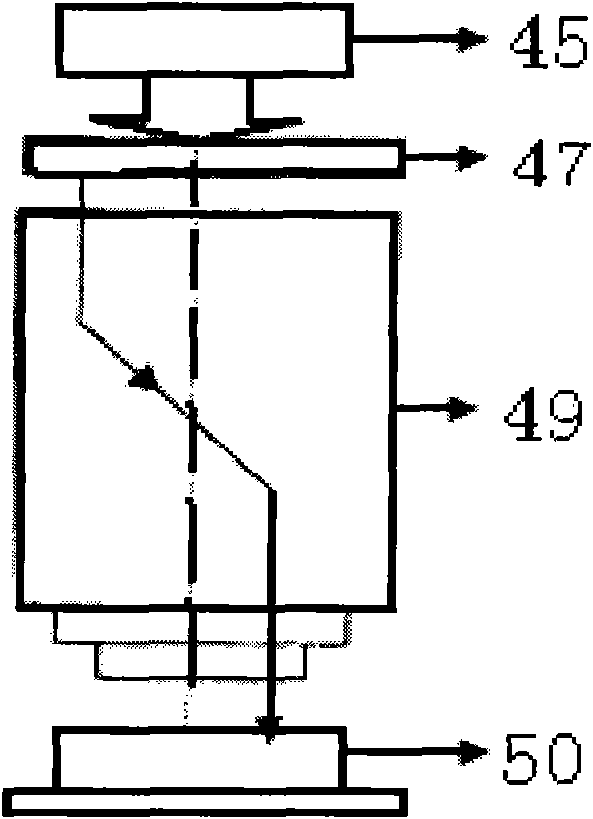

[0030] The basic principle of step and scan projection lithography machine is as follows: figure 1shown. The deep ultraviolet light from the light source 45 passes through the reticle 47 and the lens system 49 to image a part of the pattern on the reticle on a chip of the silicon wafer 50 . The reticle and the silicon wafer move synchronously in reverse at a certain speed ratio, and finally image all the patterns on the reticle on a specific chip (Chip) of the silicon wafer. The basic function of the wafer motion positioning system (wafer stage) is to carry the wafer during the exposure process and move according to the set speed and direction, so as to realize the precise transfer of the mask pattern to each area on the wafer.

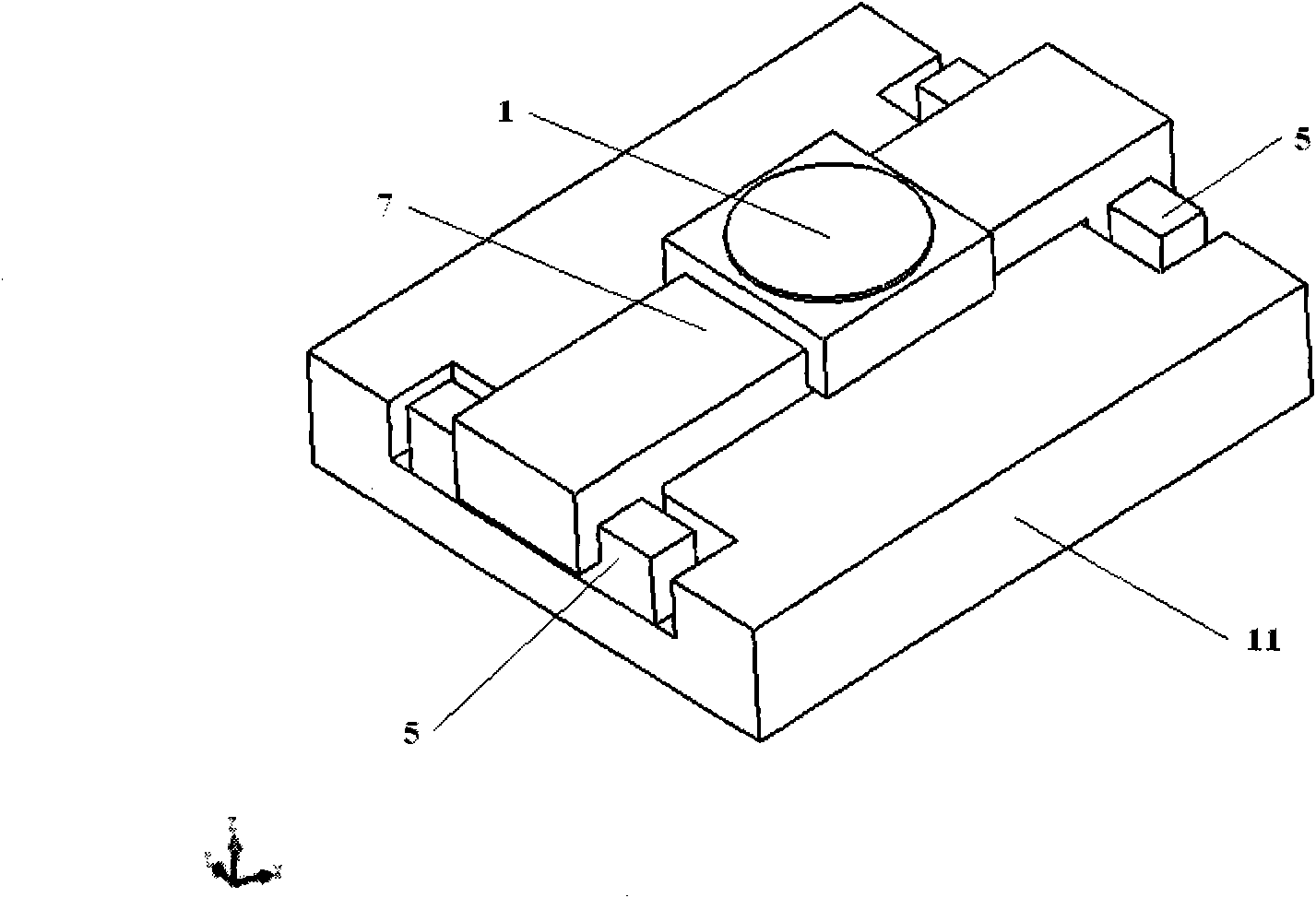

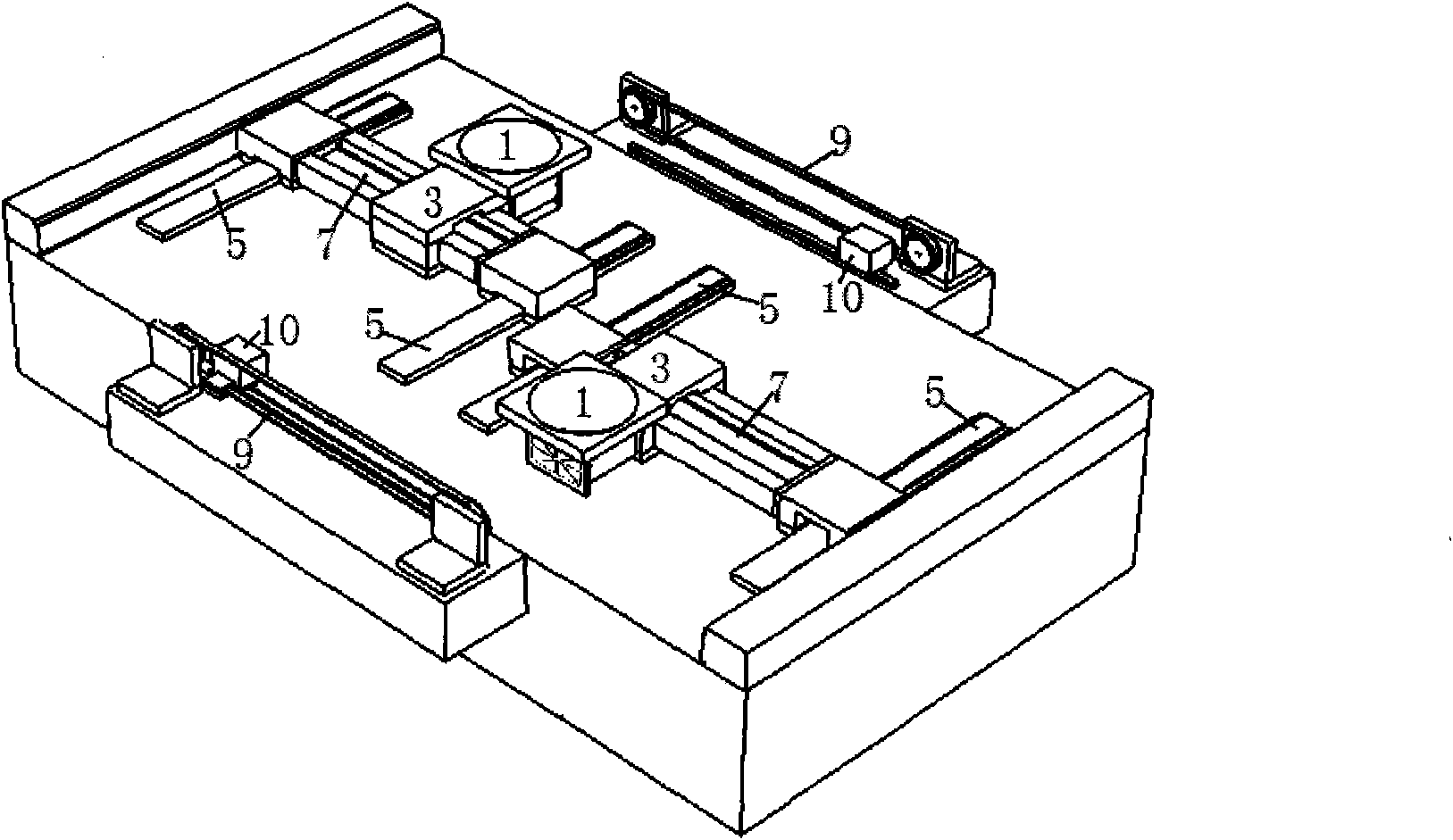

[0031] The traditional step-and-scan projection lithography wafer stage such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com