Compound premix for laying period of layers

A technology of compound premix and egg production period, which is applied in animal feed, animal feed, additional food elements, etc., can solve the problems of egg quality decline, low protein concentration, a large number of blood spot eggs, etc., and achieve disease resistance and stress resistance Strong stimulation, stable egg production performance, and good egg quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

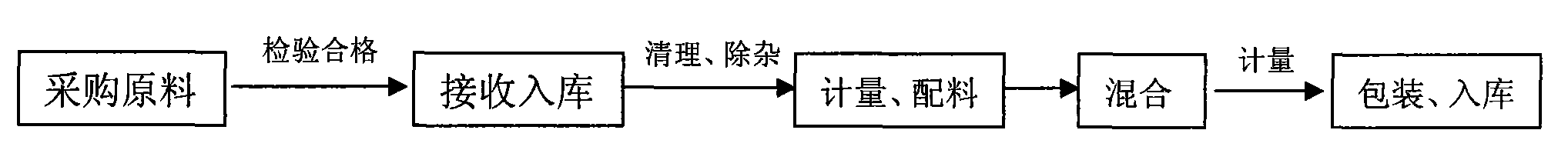

[0031] Embodiment 1-3, preparation laying hen laying period compound premix

[0032] Mix the components in Table 2 below to prepare compound trace elements, mix the components in Table 3 below to prepare compound vitamins, then mix the prepared compound trace elements and compound vitamins with other components in Table 1, A compound premix for laying hens is prepared.

[0033] Table 1. The composition of the compound premix during the laying period of laying hens (each component is calculated by mass fraction)

[0034] raw material

Example 1

Example 2

Example 3

DL-methionine

27

30

33

22.5

25

27.5

2

2

2.2

180

200

220

stone powder

135

150

165

salt

72

80

88

fine bran

526.5

478

429.3

Compound trace elements

...

Embodiment 4

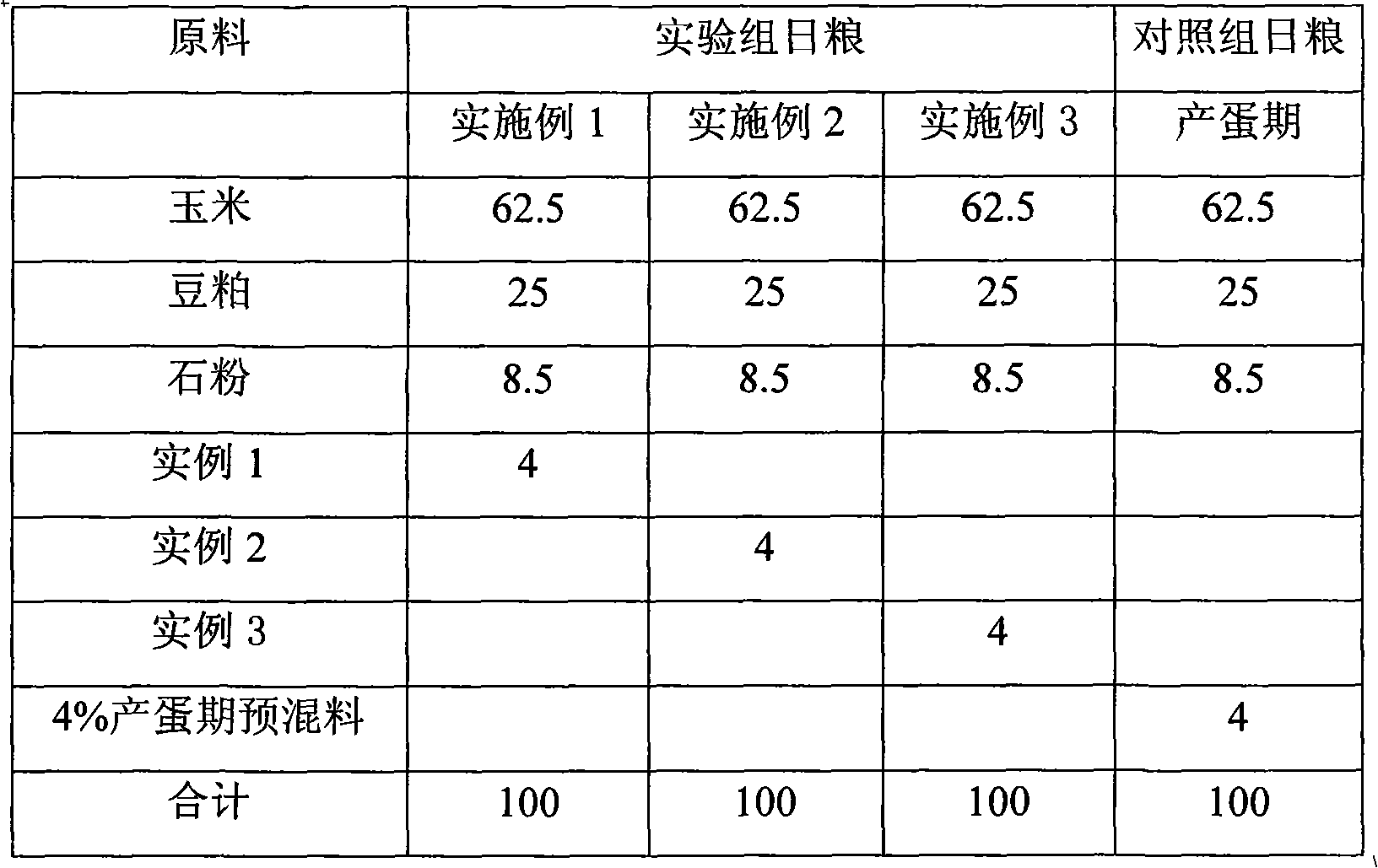

[0040] Embodiment 4, laying hen laying stage composite premix effect test

[0041] 1. Materials and methods

[0042] 1.1 Test material

[0043] The laying hen compound premix prepared in the above-mentioned Examples 1-3; the commercially available 4% laying hen premix, added according to the product instructions, was the control group.

[0044] In the commercially available 4% laying hen premix, the labeled amount of active ingredients per kilogram is shown in the table below:

[0045] product code

Commercially available 4% laying hen compound premix

use stage

laying period

Vitamin A, KIU≥

500

Vitamin D, KIU≥

180

Vitamin E, IU≥

650

Vitamin K3, mg≥

130

Vitamin B1, mg≥

120

Vitamin B2, mg≥

300

Vitamin B6, mg≥

250

Vitamin B12, mg≥

5

Niacin, mg≥

1100

Pantothenic acid, mg≥

400

Folic acid, mg≥

50

Biotin, mg≥

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com