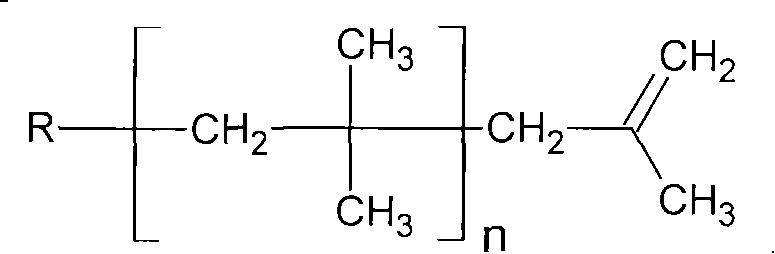

Method for preparing polyisobutylene with high reaction activity

A high-reactivity, polyisobutylene technology, applied in the field of preparation of high-reactivity polyisobutylene, can solve problems such as equipment corrosion and damage, achieve the effects of reducing acidity, increasing the content of α-double bonds, and reducing the possibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Under the protection of high-purity nitrogen, add 0.62 mmol of 2-ethylhexanol and 0.44 mmol of AlCl to 20 ml of a solution containing isobutene (IB) and dichloromethane ([IB]=2.0 mol / L) 3 The complex initiates the polymerization of isobutylene, reacts at 0°C for 20min, and adds 1ml of 0.1g / L NaOH / C 2 h 5 OH solution to terminate the reaction. The polymer product was precipitated with ethanol, washed repeatedly with deionized water and ethanol, and finally dried in a vacuum oven at 40°C for 24 hours to remove volatile impurities. IB conversion was 46%. The number-average molecular weight of polymerization product 2700g / mol, molecular weight distribution index (M w / M n ) was 1.9, and the terminal α-double bond content was 90%.

Embodiment 2

[0021] Under the protection of high-purity nitrogen, add 0.66mmol of 2-ethylbutanol and 0.44mmol of AlCl to the solution of 20ml of IB and methylene chloride ([IB]=2.0mol / L) 3 The complex initiates the polymerization of isobutylene, reacts at 0°C for 20min, adds 1ml of 0.1g / L NaOH / C 2 h 5 OH solution to terminate the reaction. The polymer product was precipitated with ethanol, washed repeatedly with deionized water and ethanol, and finally dried in a vacuum oven at 40°C for 24 hours to remove volatile impurities. IB conversion was 45%. The number-average molecular weight of polymerization product 1800g / mol, molecular weight distribution index (M w / M n ) was 1.8, and the terminal α-double bond content was 92%.

Embodiment 3

[0023] Under the protection of high-purity nitrogen, add 0.57mmol of n-hexanol and 0.44mmol of AlCl to the solution of 20ml of IB and dichloromethane ([IB]=2.0mol / L) 3 The complex initiates the polymerization of isobutylene, reacts at 0°C for 20min, adds 1ml of 0.1g / L NaOH / C 2 h 5 OH solution to terminate the reaction. The polymer product was precipitated with ethanol, washed repeatedly with deionized water and ethanol, and finally dried in a vacuum oven at 40°C for 24 hours to remove volatile impurities. The IB conversion rate was 42. The number average molecular weight of the polymerized product was 1700 g / mol, and the terminal α-double bond content was 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com