Method for preparing biodiesel by using microalgae lipid as raw material

A biodiesel and microalgae oil technology, applied in the field of bioengineering and clean energy, can solve the problems of environmental restrictions, long growth cycle, high price, etc., and achieve the effects of reducing environmental pollution, high industrial value, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

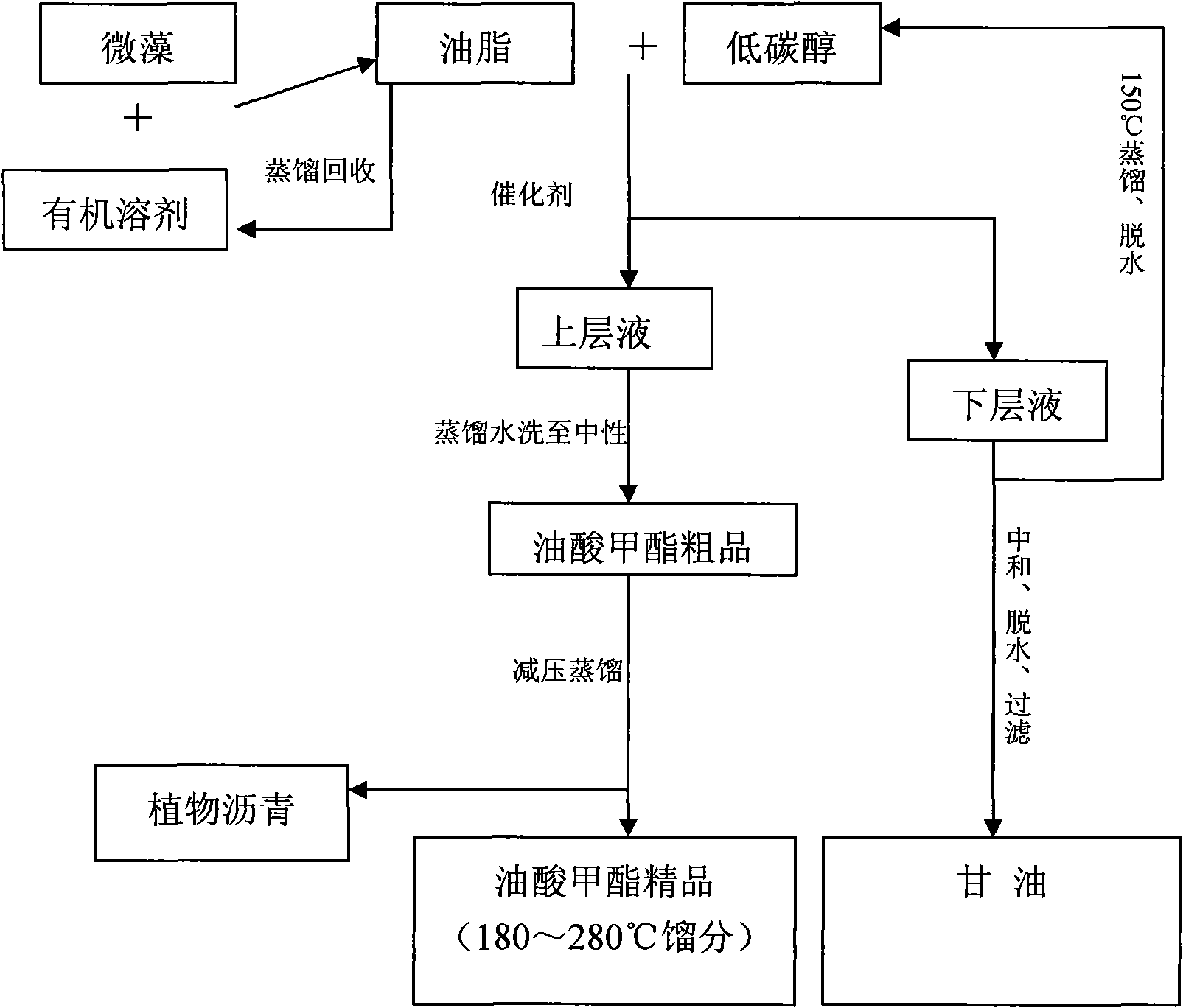

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Utilize the organic solvent extraction method to carry out the extraction of microalgae oil

[0035] Collect Dunaliella salina by centrifugation, then add water and n-hexane at a mass ratio of algae:water:n-hexane of 1:2:3, vibrate to extract microalgae oil, after standing for a period of time, the supernatant is oil extraction liquid, the supernatant was distilled under normal pressure at 70-100°C to obtain microalgae oil, and the distilled n-hexane was recovered and recycled.

Embodiment 2~5

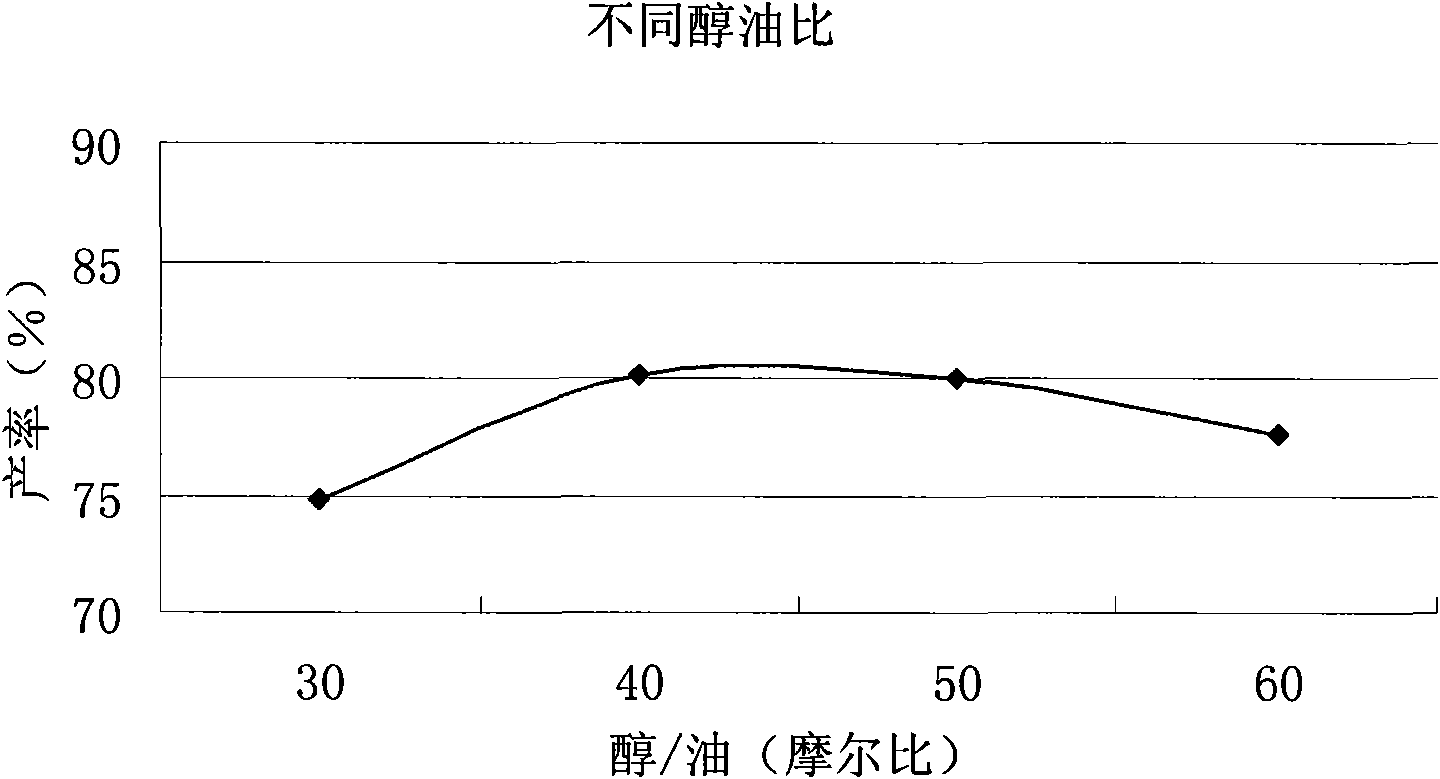

[0036] Examples 2-5: Effects of different alcohol-oil molar ratios on the yield of microalgae biodiesel

[0037] The reaction conditions are: the molar ratio of alcohol to oil is 30:1, 40:1, 50:1, 60:1 respectively, and the reaction temperature is 70°C. Catalyst 98% concentrated sulfuric acid consumption is 100% (based on raw material oil weight). Reaction time 4h.

[0038] Add the microalgae oil and methanol prepared in Example 1 into a four-necked flask, and add the catalyst concentrated sulfuric acid dropwise from a constant pressure dropping funnel, seal the four-necked flask, stir, and reflux. The four-neck flask was heated by an oil bath. After the reaction is over, separate the upper and lower layers in a separating funnel, namely the crude product and the crude glycerin layer, and obtain biodiesel fines and glycerin after distillation and other methods. Methanol is recovered by distillation and can be recycled.

[0039] During the reaction, the amount of small mole...

Embodiment 6~14

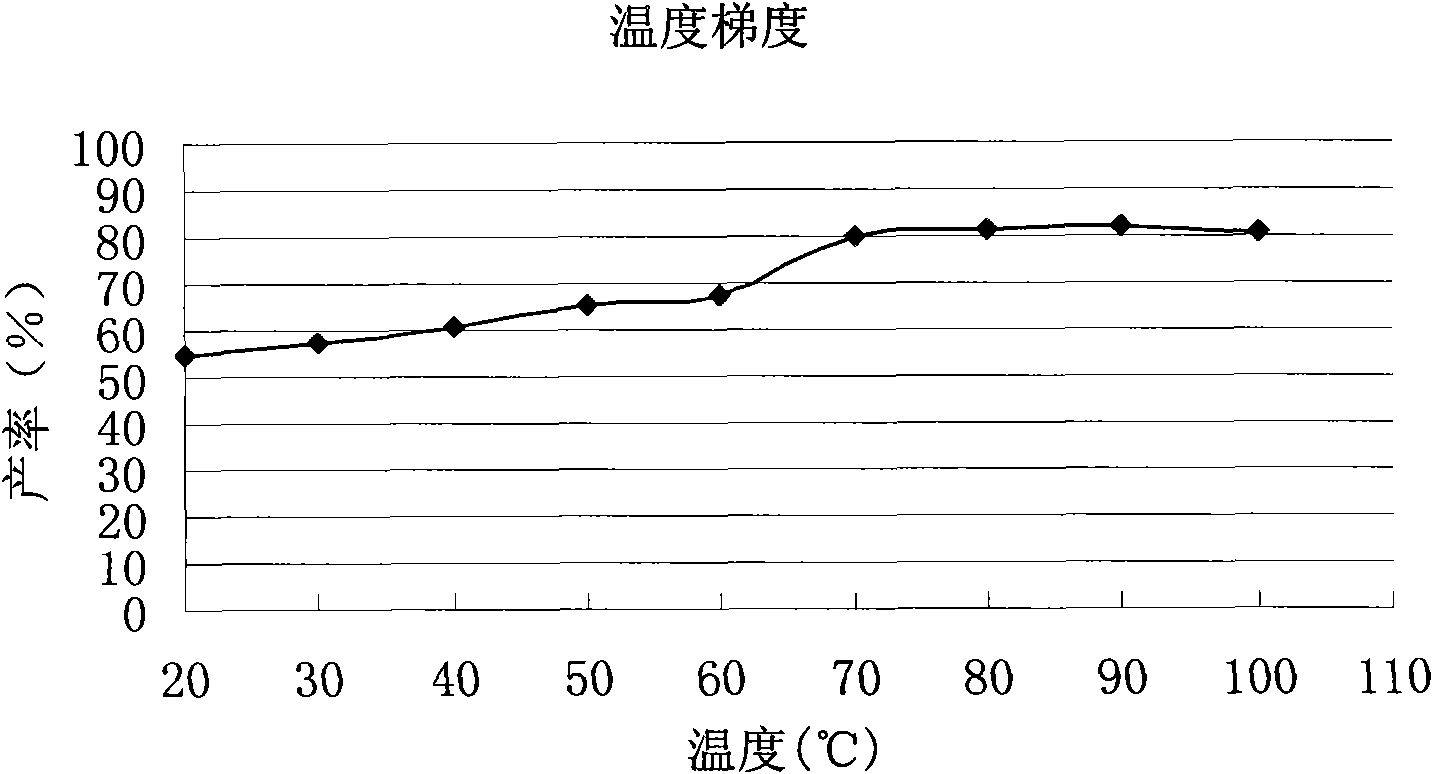

[0040] Examples 6-14: Effects of different reaction temperatures on the yield of microalgae biodiesel

[0041] The reaction conditions are: the molar ratio of alcohol to oil is 40:1, and the reaction time is 4h. Temperature is 20 ℃, 30 ℃, 40 ℃, 50 ℃, 60 ℃, 70 ℃, 80 ℃, 90 ℃, 100 ℃ respectively, and the consumption of catalyst 98% concentrated sulfuric acid is 100% (based on raw oil weight).

[0042] Add the microalgae oil and methanol prepared in Example 1 into a four-necked flask, and add the catalyst concentrated sulfuric acid dropwise from a constant pressure dropping funnel, seal the four-necked flask, stir, and reflux. The four-neck flask was heated by an oil bath. After the reaction is over, separate the upper and lower layers in a separating funnel, namely the crude product and the crude glycerin layer, and obtain biodiesel fines and glycerin after distillation and other methods. Methanol is recovered by distillation and can be recycled.

[0043] When the reaction tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com