Antiskid glass

A technology of glass and anti-slip layer, which is applied in the direction of glass/slag layered products, layered products, chemical instruments and methods, etc., which can solve the problem of anti-slip layer wear resistance, lower friction coefficient, and the outer surface of the printed glaze layer that is not easy to float , reduction of emery distribution rate, etc., to achieve good wear resistance, eliminate trachoma, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

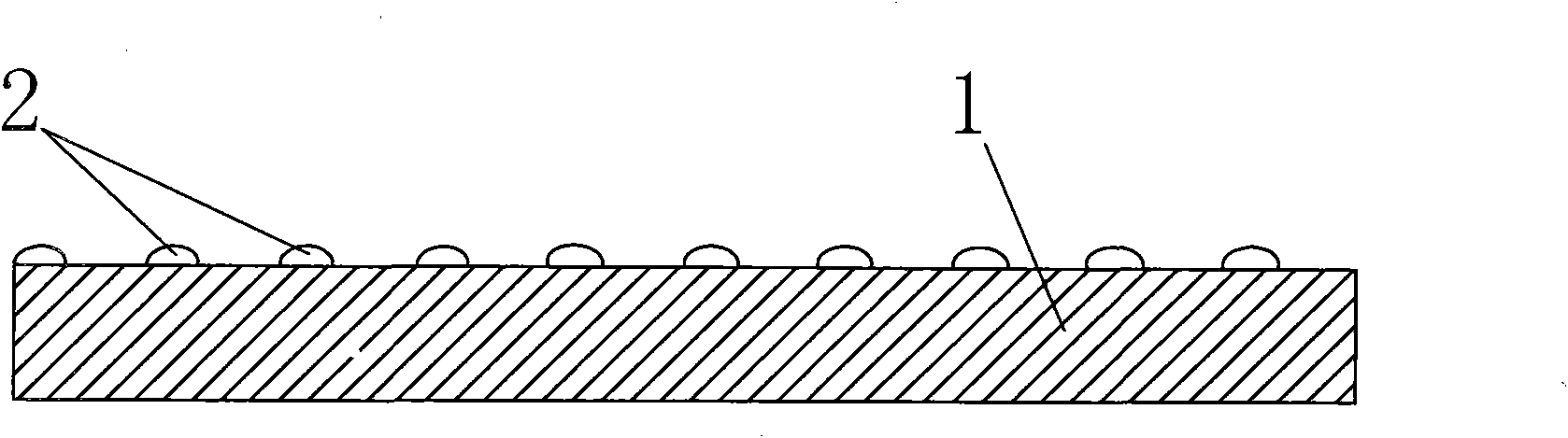

[0019] Such as figure 1 The shown anti-slip glass includes a flat glass 1 with a thickness of 15 mm, and the surface of the flat glass 1 is sintered to form an anti-slip layer 2 distributed in granular form.

[0020] The manufacturing process of this embodiment is as follows:

[0021] According to weight percentage, it is: 53.85% of base glaze, 40% of sand grains, 1.5% of active agent and 6% of accelerator. The base glaze is high-temperature ink; the sand grains are corundum with a particle size of 100 to 150 mesh; the active agent is a mixture of sodium dodecylbenzenesulfonate and polyol (hexahydric alcohol is used in this embodiment) , the weight ratio of sodium dodecylbenzenesulfonate and polyhydric alcohol is 2: 3; A mixture of phenols, the weight ratio of sulfenamide and resorcinol is 3:4; the above raw materials are mixed and stirred evenly in proportion, and then screen-printed on the surface of flat glass 1 to form a glaze layer, and the thickness of the printed glaz...

Embodiment 2

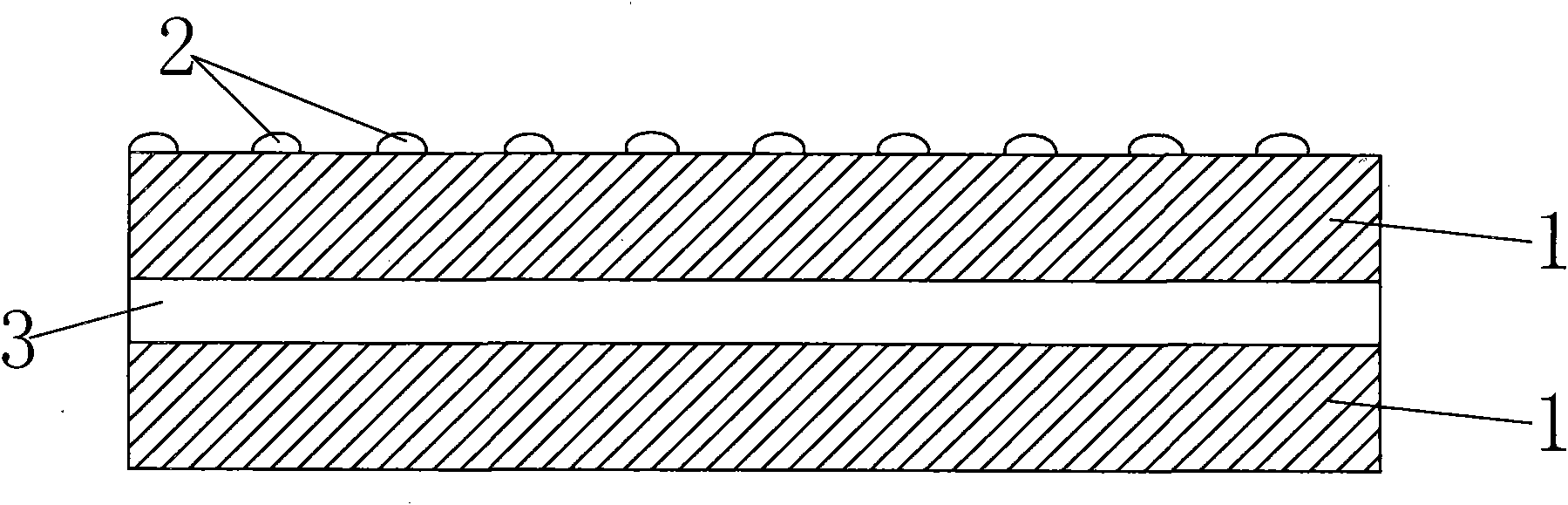

[0023] Such as figure 2 The shown anti-slip glass comprises two layers of flat glass 1 with a thickness of 10 mm, and a PVB interlayer between the two layers of flat glass 1 to form a laminated glass. The surface of the upper flat glass 1 is sintered to form particles distributed Anti-skid layer2.

[0024] The manufacturing process of this embodiment is as follows:

[0025] According to weight percentage, it is: 79.9% of base glaze, 15% of sand grains, 5% of active agent and 1‰ of accelerator. The base glaze is high-temperature ink; the sand grains are white corundum with a particle size of 60 to 100 mesh; Mixture, the weight ratio of described sodium dodecylbenzene sulfonate and polyhydric alcohol is 2: 3; A mixture of diphenols, the weight ratio of sulfenamide and resorcinol is 3:4; the above raw materials are mixed and stirred evenly in proportion, and then screen-printed on the surface of flat glass 1 to form a glaze layer, and the thickness of the printed glaze layer ...

Embodiment 3

[0027] A kind of antiskid glass, product structure is identical with embodiment 2, and the manufacturing process of present embodiment is as follows:

[0028] According to weight percentage, it is: 65% of base glaze, 28% of sand, 3% of active agent and 4% of accelerator. The base glaze is high-temperature ink; the sand grains are white corundum with a particle size of 60 to 100 mesh; Mixture, the weight ratio of described sodium dodecylbenzene sulfonate and polyhydric alcohol is 2: 3; A mixture of diphenols, the weight ratio of sulfenamide and resorcinol is 3:4; the above raw materials are mixed and stirred evenly in proportion, and then screen-printed on the surface of flat glass 1 to form a glaze layer, and the thickness of the printed glaze layer is 0.75mm~ 2mm, the screen mesh number of screen printing is 60 mesh; after the glaze layer is dry, the above flat glass is sent to the tempering furnace for high temperature tempering at a temperature of 650°C to 720°C, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com