Surface acoustic wave pressure sensor

A technology of pressure sensor and surface acoustic wave, which is applied in the field of surface acoustic wave pressure sensor, can solve the problems of increasing the complexity of manufacturing, installation and packaging design, poor structural stability design and installation structure, and complicated substrate manufacturing. Achieve the effects of volume reduction, sensitivity improvement, and sensitivity enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

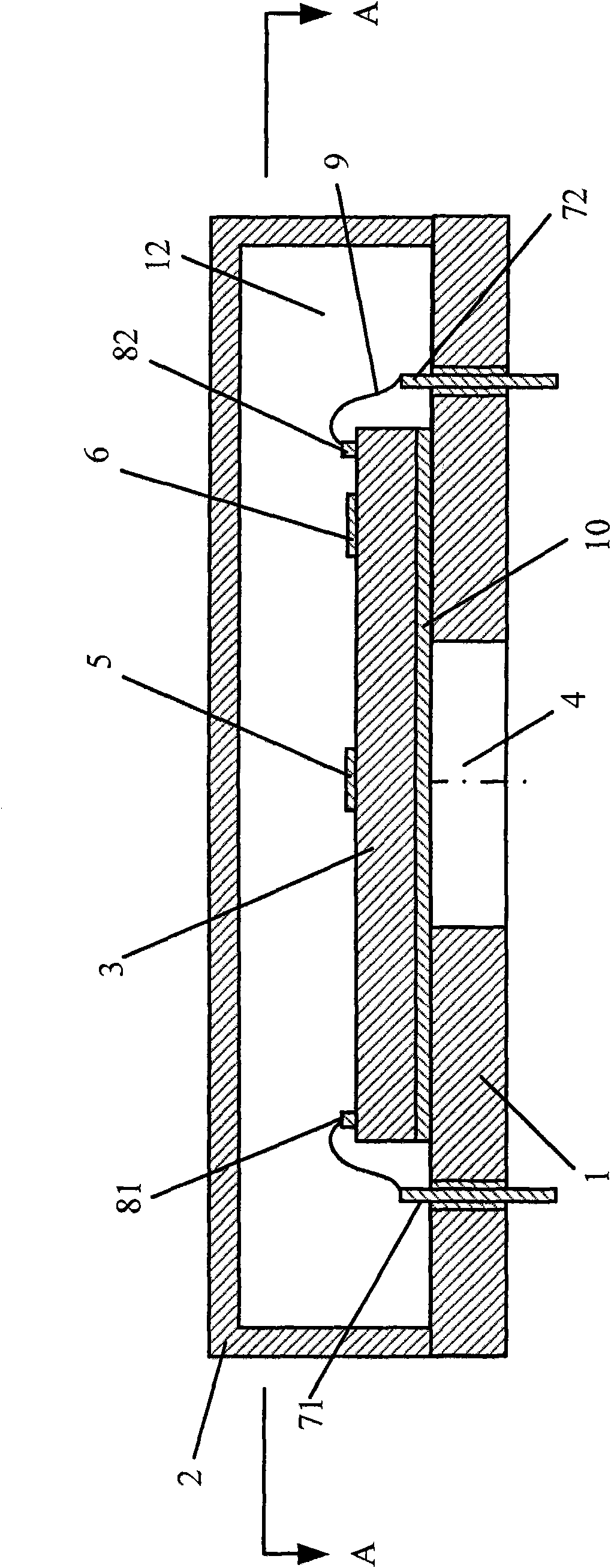

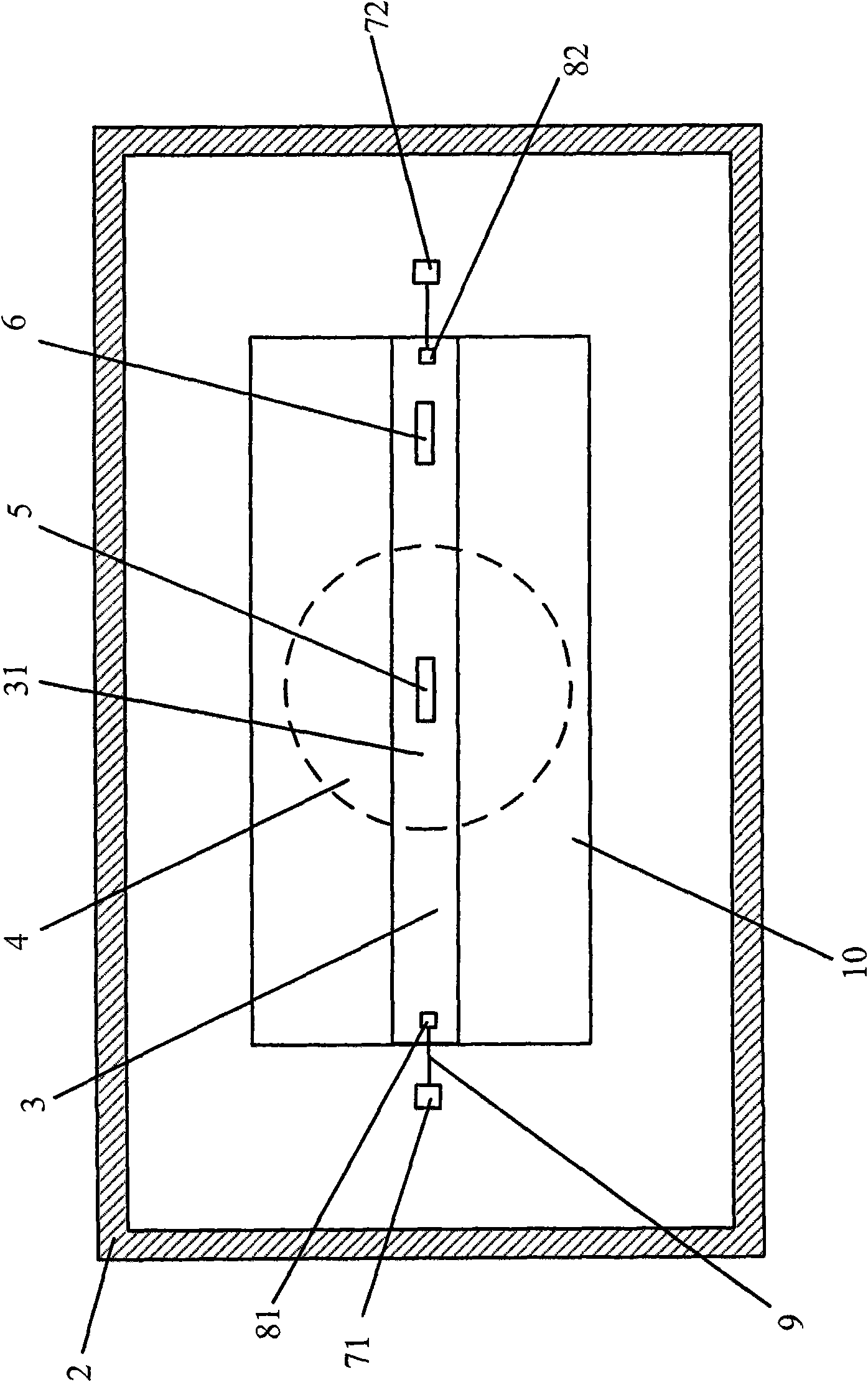

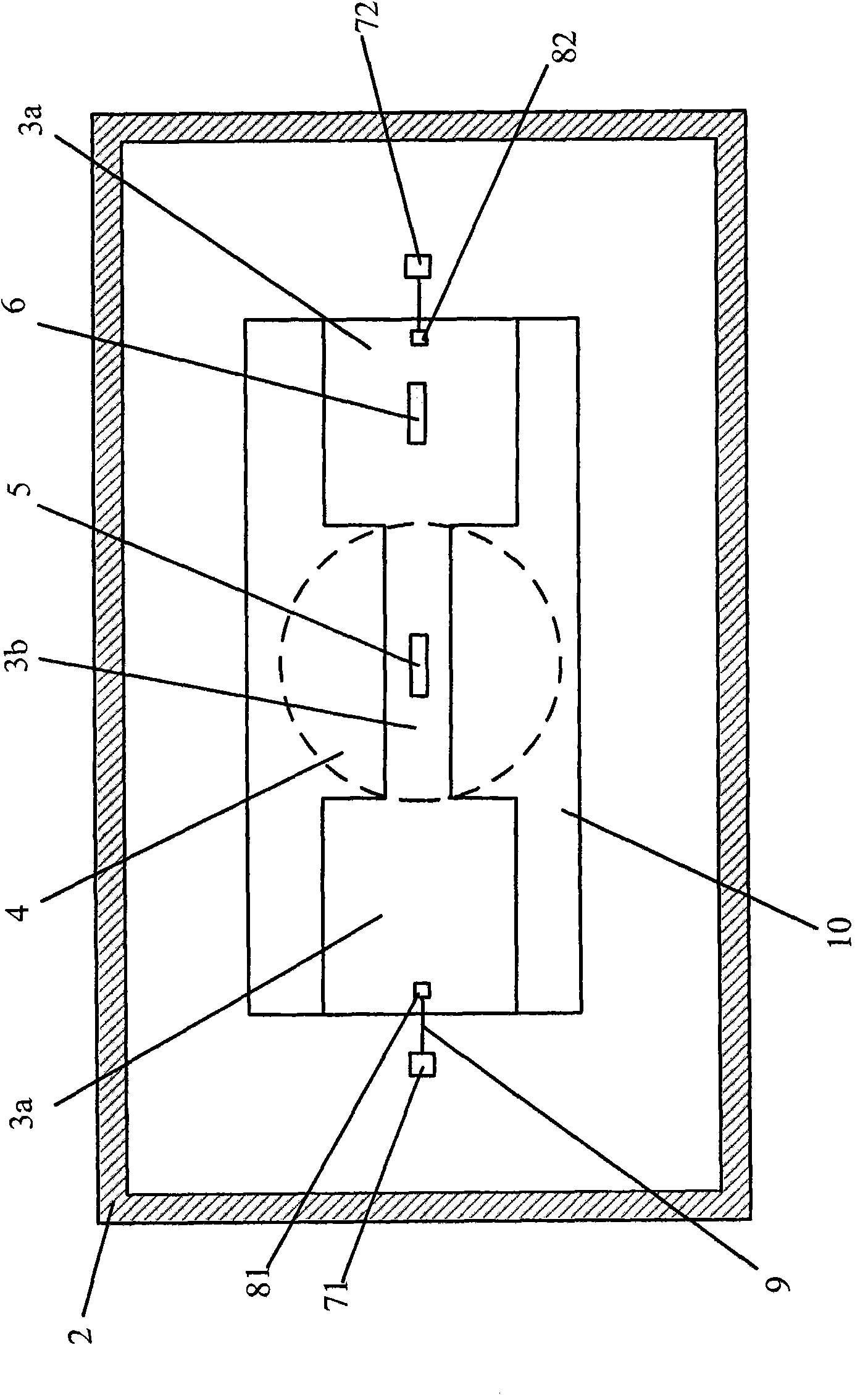

[0019] Such as figure 1 As shown, the surface acoustic wave fluid pressure sensor of the present invention includes a base 1 and a top cover 2. The base 1 is made of a material with a low temperature conductivity, such as plastic, which can reduce the influence of temperature on the sensor. The top cover 2 is hermetically installed on the base 1, and the material selected for the top cover 2 should ensure the smooth passage of wireless electromagnetic wave signals, so as not to shield the wireless signals, such as plastics and ceramics.

[0020] A fluid diaphragm 10 is fixed on the inner surface of the base 1 , and the pressure conduction through hole 4 on the base 1 can be used to guide the pressure of the fluid to the fluid diaphragm 10 . The fluid membrane 10 is a thin film with a small elastic modulus and a low temperature conductivity, which can transmit pressure to the substrate 3 and at the same time isolate the temperature, so that the substrate 3 is sensitive to press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com