Preparation method of flavor type compound sweet corn beverage

A technology of sweet corn and sweet corn juice, which is applied in the field of food processing, can solve the problems of low juice yield and precipitation, and achieve the effects of unique flavor, attractive color and promoting growth and development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

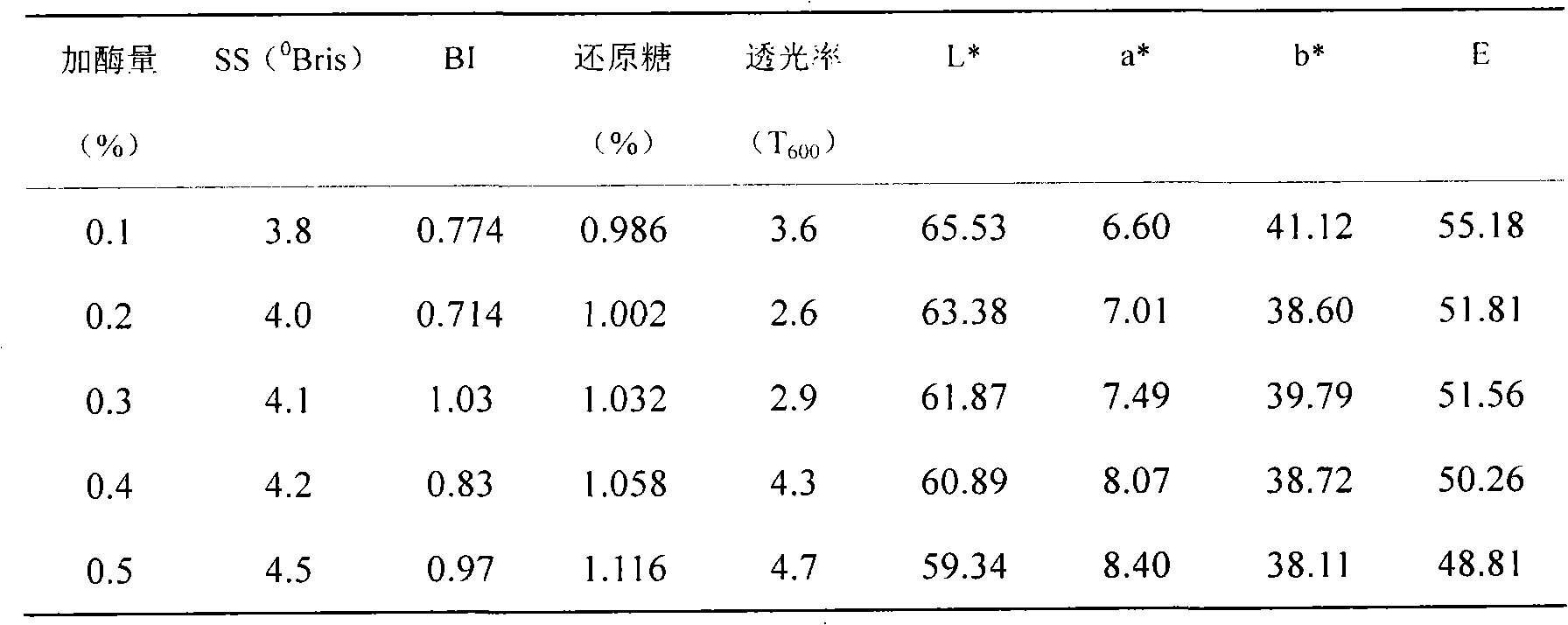

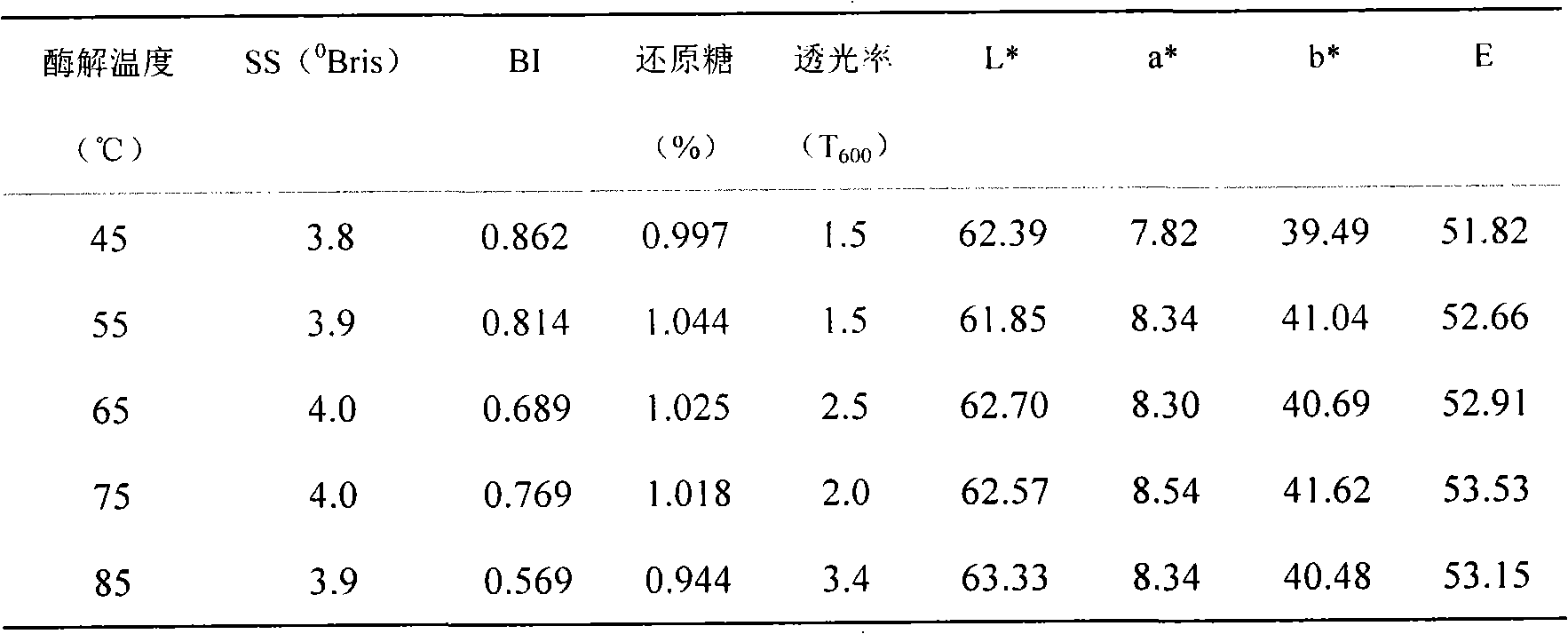

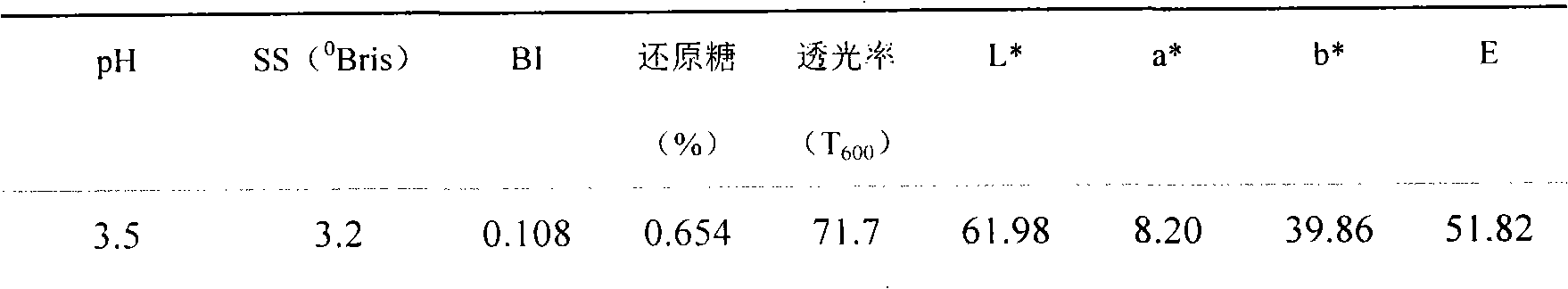

[0020] Select 50 kg of Jingtian No. 5 sweet corn, remove bracts and filaments, and thresh; soak in hot water at 70°C for 20 minutes, and the ratio of material to water should be controlled at 1:4. Put the materials into a beater for crushing and beating, boil the obtained corn syrup for 10 minutes, cool the gelatinized mash to 65°C, adjust the pH to 5.5 with citric acid, and then add 0.2% α-amylase (Novozymes) Liquefaction was carried out for 60 minutes. During this process, the enzymatic hydrolysis process parameters were optimized through a single factor test (see Table 1); the obtained corn steep liquor was boiled for 15 minutes to completely inactivate the enzyme, and the temperature was lowered to 55° C., and the pH was adjusted to 4.5 with citric acid. Add 0.05% chitosan to make the corn juice clear and transparent, and filter through 200 order nylon cloth to obtain 68.3 kilograms of sweet corn juice.

[0021] Select 50 kg of red core No. 6 high-quality orange-red carrot...

Embodiment 2

[0046] Select 50 kg of Jingtian No. 3 sweet corn, remove bracts and filaments, and thresh; soak in hot water at 70°C for 20 minutes, and the ratio of material to water should be controlled at 1:5. Put the materials into a beater for crushing and beating, boil the obtained corn syrup for 10 minutes, cool the gelatinized mash to 65°C, adjust the pH to 5.5 with citric acid, and then add 0.25% α-amylase for liquefaction for 60 minutes; Boil the obtained corn syrup for 15 minutes to completely inactivate the enzyme, lower the temperature to 55°C, adjust the pH to 4.5 with citric acid, add 0.05% chitosan to make the corn juice clear, and filter it through 200-mesh nylon cloth to obtain sweet corn Juice 85.2 kg.

[0047]Select 50 kg of red core No. 6 high-quality carrots. After selection, remove the head and tail that are not suitable for processing, wash the remaining part, peel it, cut it into small sections with a thickness of 0.6-0.7 cm, and use 0.5% citric acid + 0.5 The soluti...

Embodiment 3

[0051] Select 50 kg of Jingtian No. 5 sweet corn, remove bract leaves and filaments, and thresh; soak in hot water at 70°C for 20 minutes, and the ratio of material to water should be controlled at 1:3. Put the materials into a beater for crushing and beating, boil the obtained corn syrup for 10 minutes, cool the gelatinized mash to 65°C, adjust the pH to 5.5 with citric acid, and then add 0.2% α-amylase for liquefaction for 60 minutes; Boil the obtained corn syrup for 15 minutes to completely inactivate the enzyme, lower the temperature to 55°C, adjust the pH to 4.5 with citric acid, add 0.05% chitosan to make the corn juice clear, and filter it through 200-mesh nylon cloth to obtain sweet corn 48.2 kg of juice.

[0052] Select 25 kg of red core No. 6 high-quality carrots. After selection, remove the head and tail tip that are not suitable for processing, wash the remaining part, peel it, cut it into small sections with a thickness of 0.6-0.7 cm, and use 0.5% citric acid + 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com