Method for preparing sugar ortho ester

A technology of sugar orthoester and monosaccharide, applied in the field of preparation of sugar orthoester, can solve the problems of large environmental pollution and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

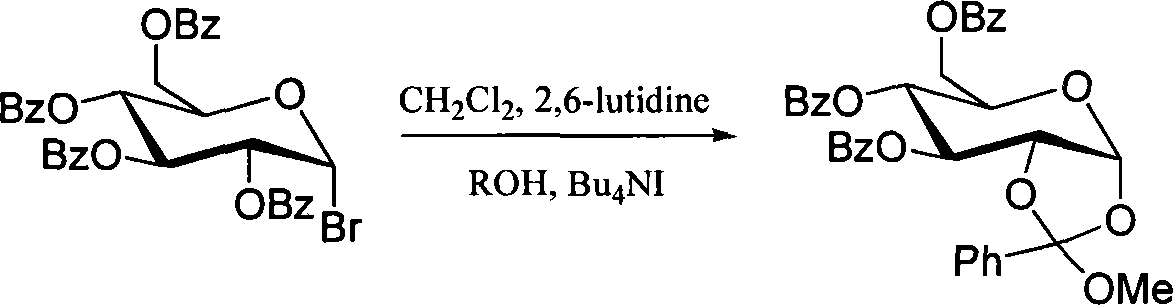

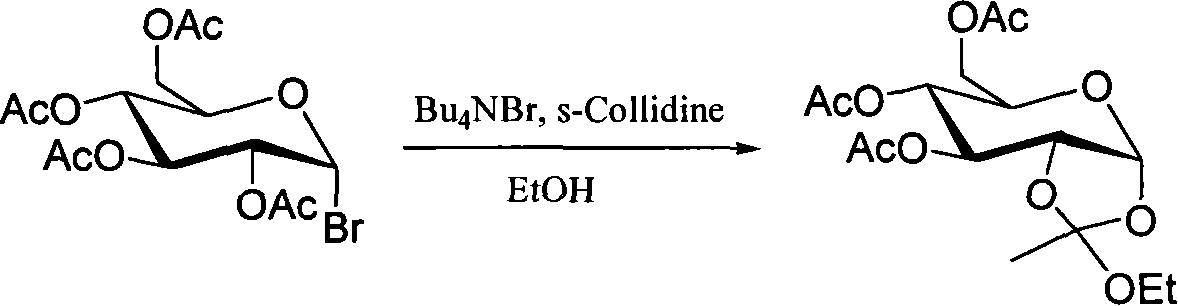

Method used

Image

Examples

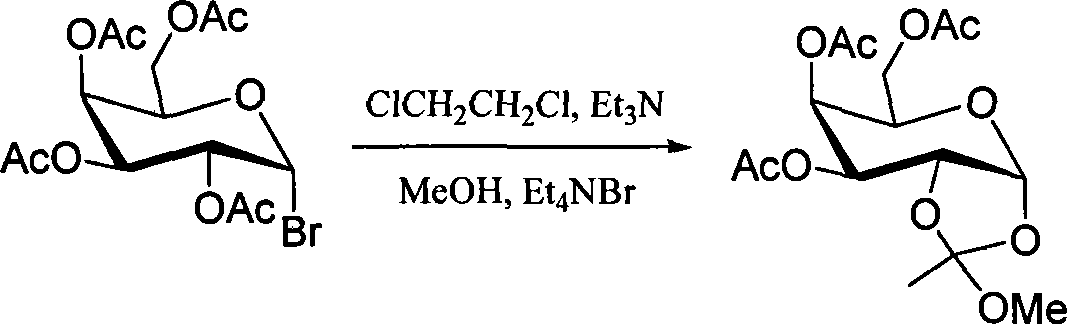

Embodiment 1

[0025] Example 1: Add 57mg 2,3,4,6-tetra-O-acetylbromoglucopyranose and 0.57mL acetonitrile to a 10mL round bottom flask, then add 45mg tetrabutylammonium bromide, 46mg sodium bicarbonate , 0.056mL methanol and 57mg Molecular sieves, stirred at 40°C for 3 hours. After the reaction was detected by TLC, it was directly concentrated under reduced pressure and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate 3:2) to obtain pure 3,4,6-tri-O-acetylpyran Glucose-1,2-(methyl orthoester) 43 mg, yield 86%.

Embodiment 2

[0026] Example 2: Add 57mg 2,3,4,6-tetra-O-acetylbromoglucopyranose and 0.57mL acetonitrile to a 10mL round bottom flask, then add 45mg tetrabutylammonium bromide, 23mg sodium bicarbonate , 0.056mL methanol and 57mg Molecular sieves, stirred at 40°C for 6 hours. After the reaction was detected by TLC, it was directly concentrated under reduced pressure and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate 3:2) to obtain pure 3,4,6-tri-O-acetylpyran Glucose-1,2-(methyl orthoester) 42 mg, yield 84%.

Embodiment 3

[0027] Example 3: Add 57mg 2,3,4,6-tetra-O-acetylbromoglucopyranose and 0.57mL acetonitrile to a 10mL round bottom flask, then add 13mg tetrabutylammonium bromide, 23mg sodium bicarbonate , 0.056mL methanol and 57mg Molecular sieves, stirred at 40°C for 6 hours. After the reaction was detected by TLC, it was directly concentrated under reduced pressure and purified by silica gel column chromatography (eluent: petroleum ether / ethyl acetate 3:2) to obtain pure 3,4,6-tri-O-acetylpyran Glucose-1,2-(methyl orthoester) 40 mg, yield 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com