Biomass energy generation device suitable for use in cold region.

A technology based on biomass in cold regions, applied in biochemical cleaning equipment, enzymology/microbiology equipment, biomass post-treatment, etc., can solve the problems of low utilization rate, poor comprehensive benefit, low decomposition rate of raw materials, etc., and achieve high efficiency Treatment, realization of recycling, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is described in more detail below in conjunction with accompanying drawing example:

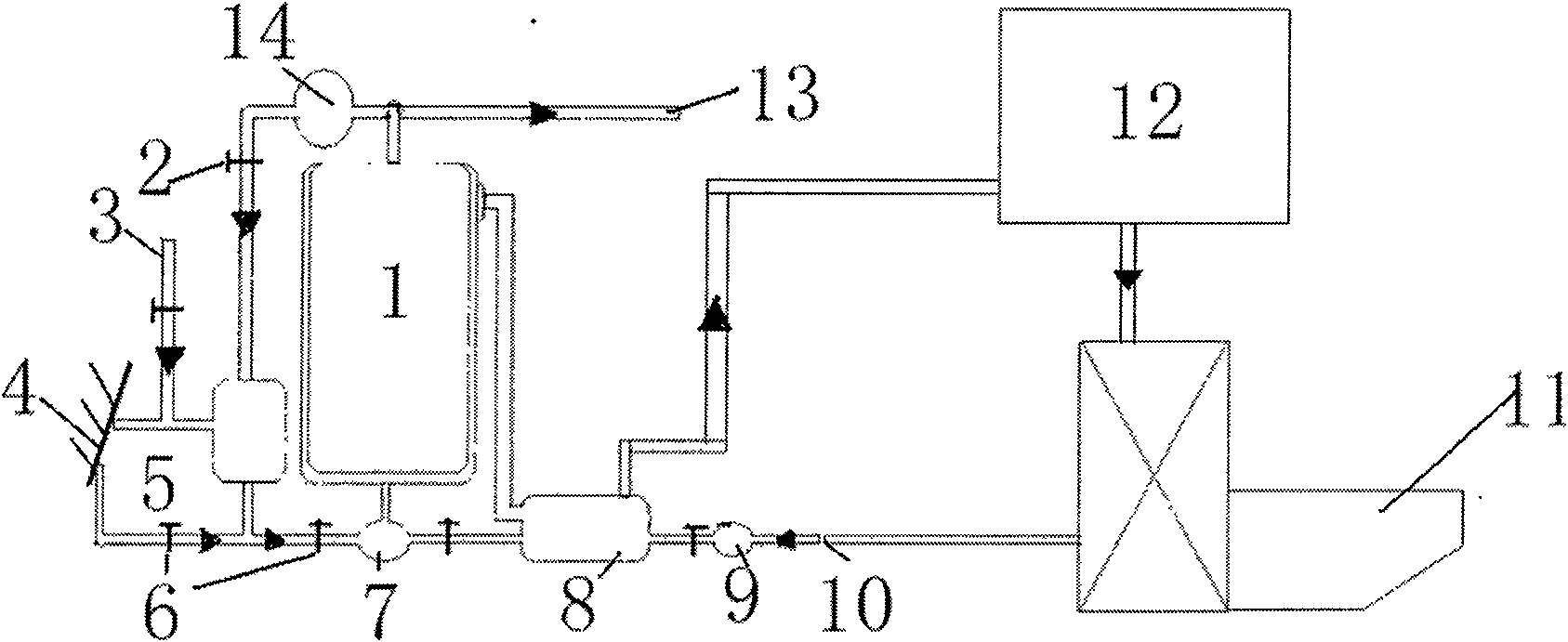

[0015] In the attached drawings: In the figure: 1 is an integrated biological fermentation device, 2 is a one-way valve, 3 is water heater inlet, 4 is a solar water heater, 5 is a gas water heater, 6 is a valve, 7 is a mixing valve, 8 is a Heat pump, 9 is a water pump, 10 is sewage to be treated, 11 is a pretreatment tank, 12 is an aerobic reactor, 13 is a methane outlet, and 14 is an alkane gas storage chamber.

[0016] Put the solid waste into the pretreatment tank 11 for pretreatment, and then the pretreated liquid to be treated is divided into two streams after passing through the water pump 9, one stream is directly fed into the water mixing valve 7, and the other stream is heated by the heating system and then passed through The water tank is mixed with cold water, the temperature of the hot and cold water is tracked by the control system, and the flow of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com