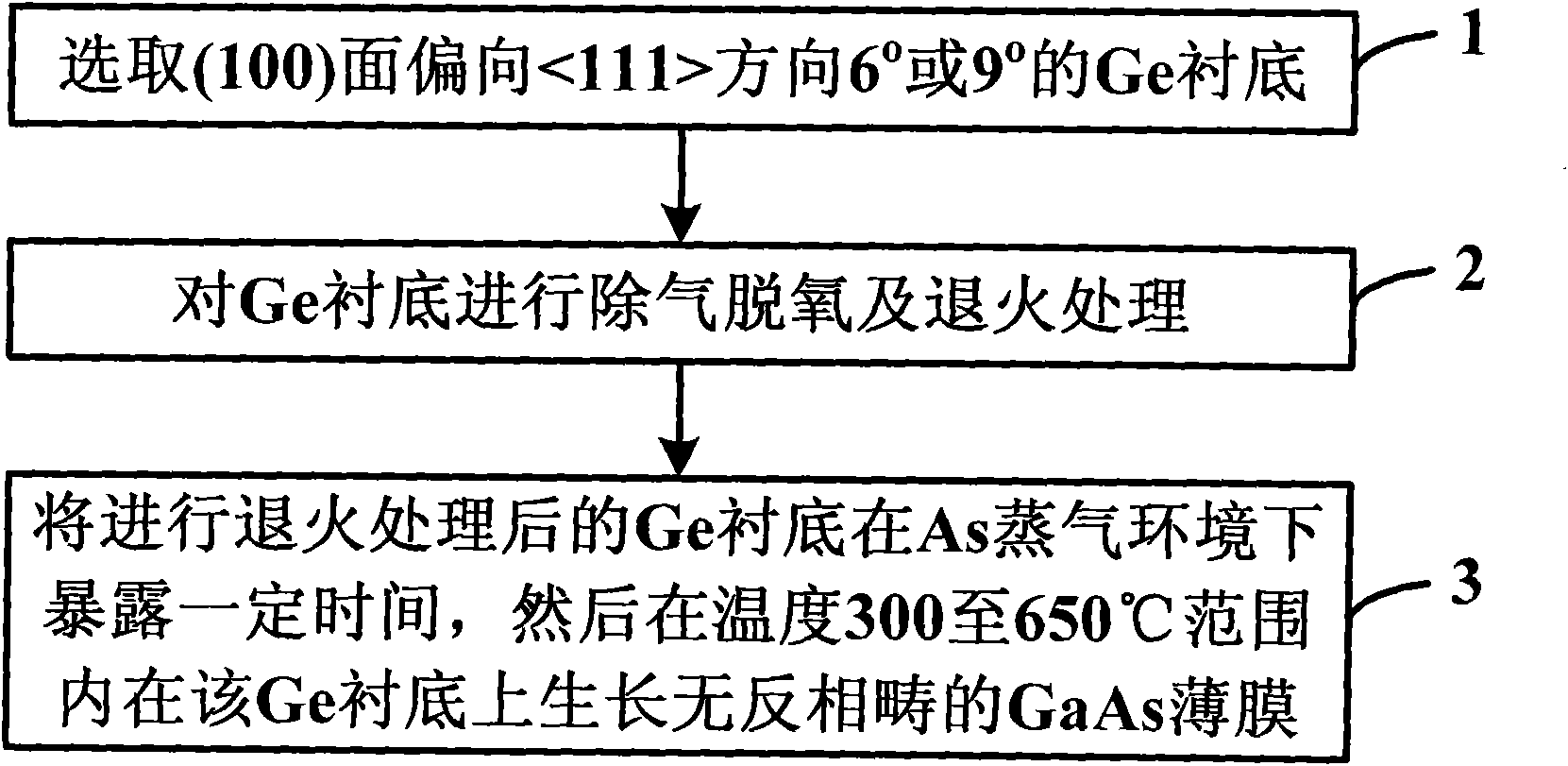

Molecular beam epitaxial method for growing non-antiphase domain gallium arsenide film on germanium substrate

A technology of molecular beam epitaxy and anti-phase domain, which is applied in chemical instruments and methods, single crystal growth, crystal growth, etc., and can solve problems such as complex epitaxy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0025] Glue the Ge substrate on the sample holder with indium (In), and introduce it into the sample chamber for baking at a temperature of 180 degrees.

[0026] The baked Ge substrate is introduced into the buffer chamber and degassed at 420 degrees, and the atmospheric pressure of the buffer chamber is reduced to 10 -8 When the Torr is below, the degassing is complete.

[0027] The degassed Ge substrate is introduced into the growth chamber, and the temperature of the substrate heater is raised, and the deoxidation and annealing of the sample are performed without As protection. Wherein the annealing temperature ranges from 500 to 700° C., and the annealing time ranges from 5 to 30 minutes.

[0028] During the anneali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com