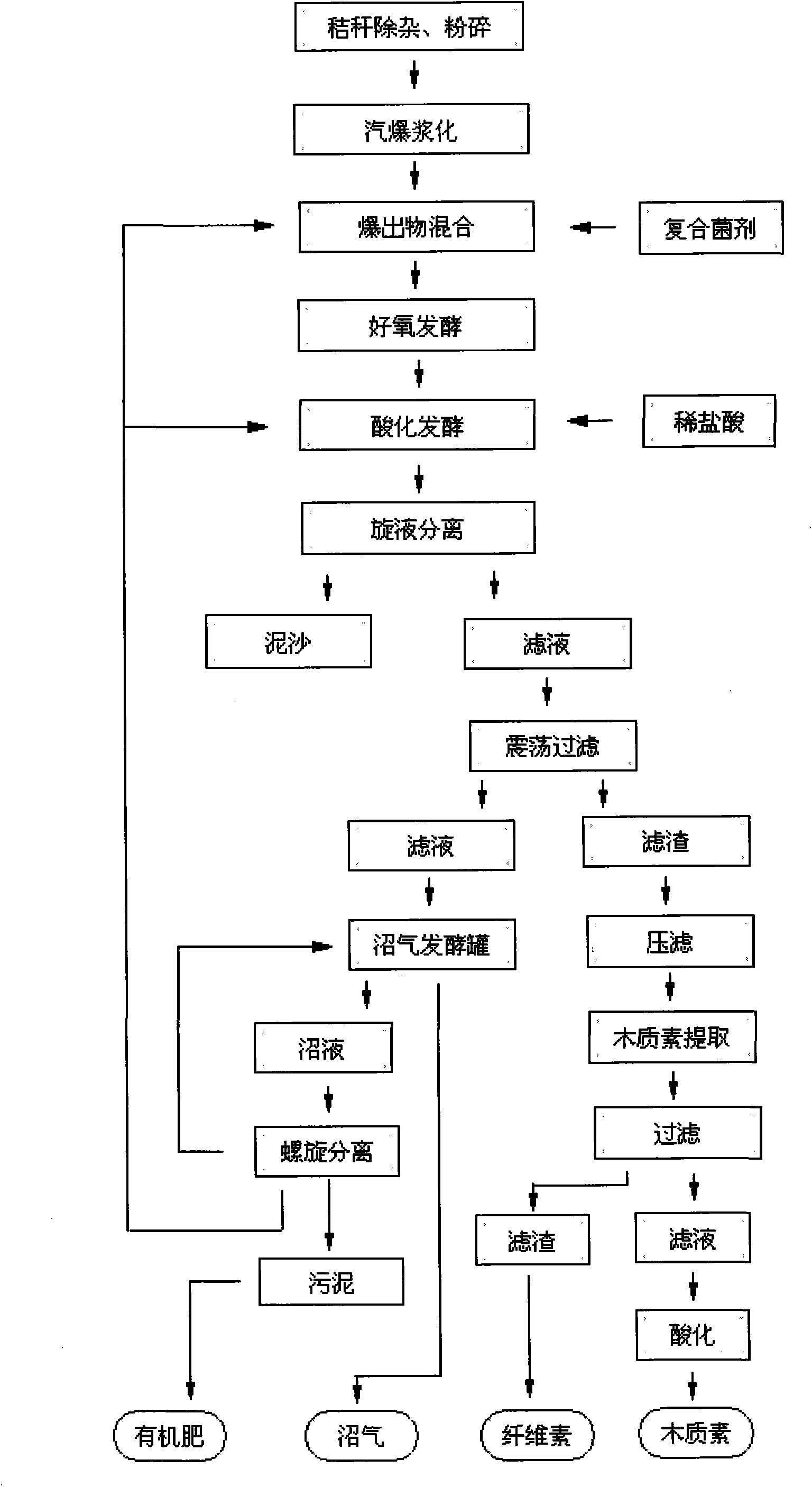

Soybean straw industrialization methane production and method for extracting cellulose and lignin

A technology for soybean straw and cellulose, which is applied in the fields of renewable energy and resources and environment, can solve problems such as unfavorable production of small and medium-sized biogas, and achieve significant economic and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0031] The annual processing of soybean straw is 30,000 tons. As a production unit, if the moisture content of the straw is 20%, the processing of soybean straw is 4.17 tons per hour, and its absolute dry weight is 3.33 tons. The cycle of aerobic fermentation and acidification fermentation is calculated as 15 days, and the cycle of biogas fermentation is calculated as 25 days. The volume of each tank is 50 cubic meters. According to the calculation of material balance, 90 acidification fermentation tanks and 210 biogas fermentation tanks are required, totaling 300, with a total volume of 15,000 cubic meters. A continuous steam explosion machine with a processing capacity of 5 tons / hour is selected for steam explosion treatment. As the hydrocyclone, a 6-10 stage hydrocyclone with a processing capacity of 12-15 cubic meters per hour is selected. The separation ratio of the spiral separator is 60-75% of the clear liquid, 20-30% of the suspension liquid, and 10-15% of the sludge,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com