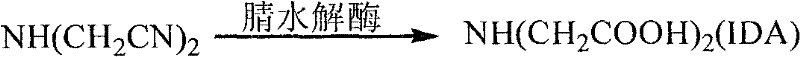

Method for preparing iminodiacetic acid from iminodiacetonitrile by microorganism catalysis

A technology for catalyzing iminodiacetonitrile and nitrilase to catalyze iminodiacetonitrile is applied in the field of strains with nitrilase activity, and can solve the problems of high equipment requirements, high energy consumption, harsh reaction conditions and the like, and achieve efficient production. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the initial screening of producing nitrilase bacterial classification

[0038] Prepare the primary screening medium per 1L as follows: yeast extract 6g, NaCl 1g, K 2 HPO 4 1g, MgSO 4 1g, 20g of agar powder, pH 7.0 water to make up to 1000mL, after sterilization, cool to 50°C, add 5g of iminodiacetonitrile and 1g of bromocresol violet, and mix well to the plate.

[0039] Collect the bacteria for screening, smear them on a plate, and culture them at a temperature of 28-30°C for 3-4 days, pick the strains that produce yellow discoloration circles in the colonies, and inoculate them on LB slopes (25-28°C);

[0040] The microbial strains in the yellow color circle are: Pseudomonas marginalis ZJB09121 (Pseudomonas marginalis ZJB09121), Pseudomonas putia ZJB09134 (Pseudomonas putia ZJB09134), Pseudomonas putia ZJB09129 (Pseudomonas putia ZJB09129), Pseudomonas putia ZJB09129 (Pseudomonas putia ZJB09129), Pseudomonas putia ZJB0913as putia ZJB09135)、荧光假单胞菌ZJB0...

Embodiment 2

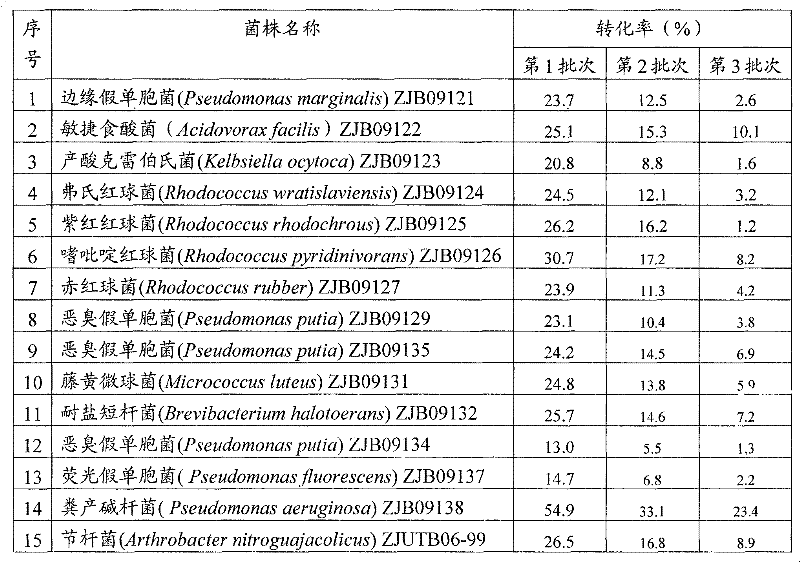

[0041] Embodiment 2: the double screening of producing nitrilase bacterial classification

[0042] Inoculate the strains screened in Example 1 that can produce discoloration reactions and have large yellow discoloration circles into the re-screening medium, 30-32°C, 100-200r / min, 500mL triangular flask with a liquid volume of 150mL, and ferment for 3 days , centrifuging the fermented liquid to obtain crude enzyme liquid or wet bacteria. Take 1g of wet bacteria respectively, place them in a 500ml Erlenmeyer flask, add 50ml of 2% (w / w) reaction substrate iminodiacetonitrile aqueous solution, react for 60min under the condition of 30°C shaker at 150r / min, and remove the bacteria by centrifugation. The production amount of iminodiacetic acid was measured, and the conversion rate was calculated. The results are shown in Table 1.

[0043] Each 1L of re-screening medium is prepared as follows: glycerin 8g, yeast extract 6g, NaCl 1g, K 2 HPO 4 5g, MgSO 4 0.2g, 5g n-butyronitrile...

Embodiment 3

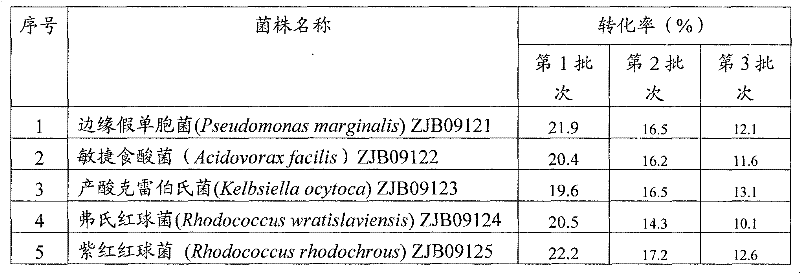

[0046] Example 3: Cultivation and biocatalytic preparation of iminodiacetic acid produced by nitrilase microorganisms

[0047] Each 1L of enzyme production medium is prepared as follows: glycerin 8g, yeast extract 6g, NaCl 1g, K 2 HPO 4 5g, MgSO 4 0.2g, make up to 1000mL with water; add 5g of inducer n-butyronitrile.

[0048] The enzyme production medium was divided into 500mL Erlenmeyer flasks with a liquid volume of 100mL / bottle, and was sterilized by heat in a sterilizing pot for 20min at a temperature of 121°C.

[0049] The strains obtained in Example 1 were respectively inoculated with 1 ring of strains activated on a slant to the enzyme production medium added with an inducer, and cultured for 3 days at a shaker flask with a rotation speed of 200 r / min and a temperature of 30°C. Wet cells were collected as crude nitrilase enzyme. Add 5g of wet bacteria to 100mL of 3% (w / w) iminodiacetonitrile aqueous solution for hydrolysis reaction, control the temperature at 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com