Nano-meter far infrared cloth

A far-infrared and nano-technology, applied in textiles, papermaking, fiber processing, etc., can solve the problems of low far-infrared components, insufficient far-infrared release rate to improve human health, and insufficient far-infrared release rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

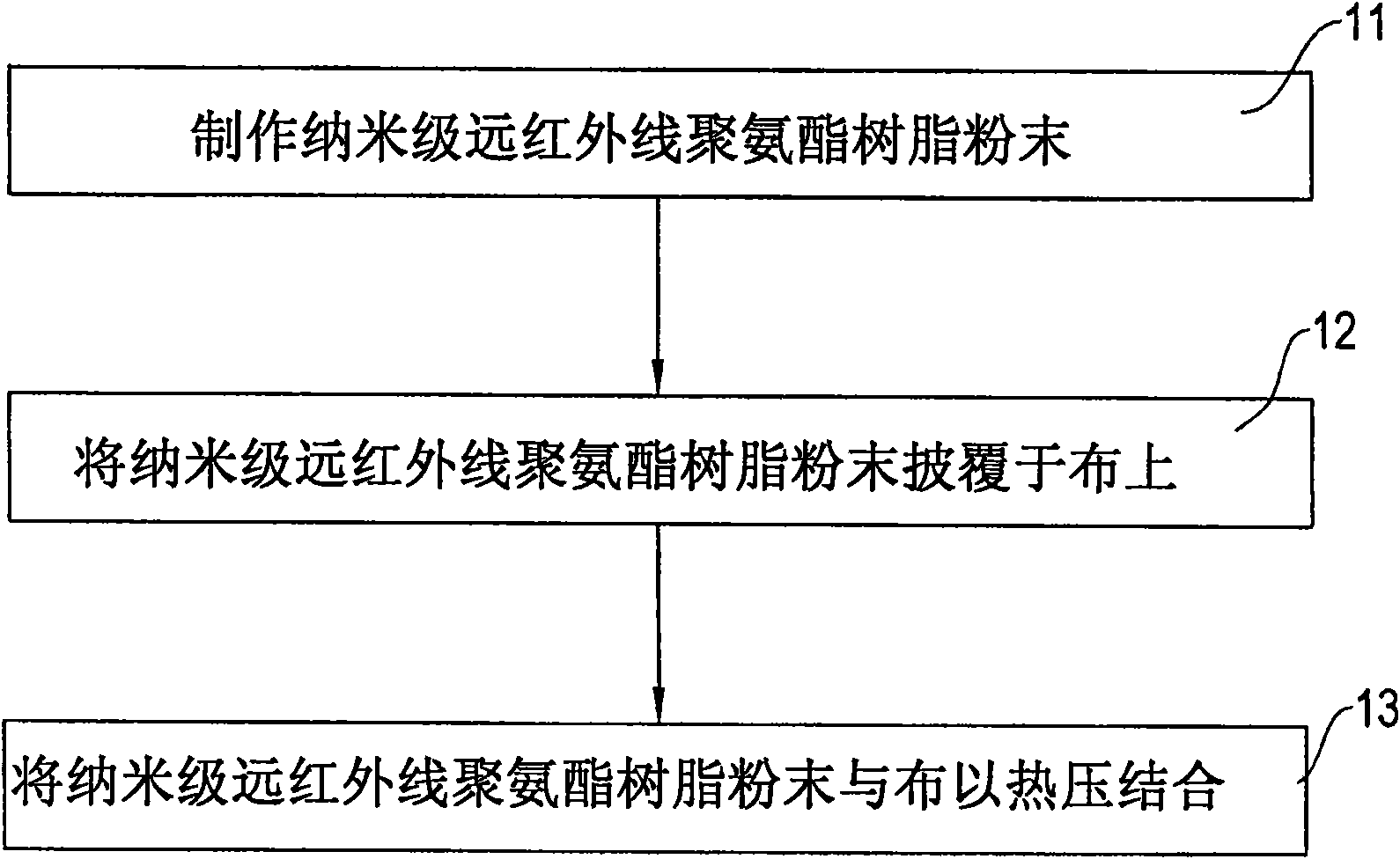

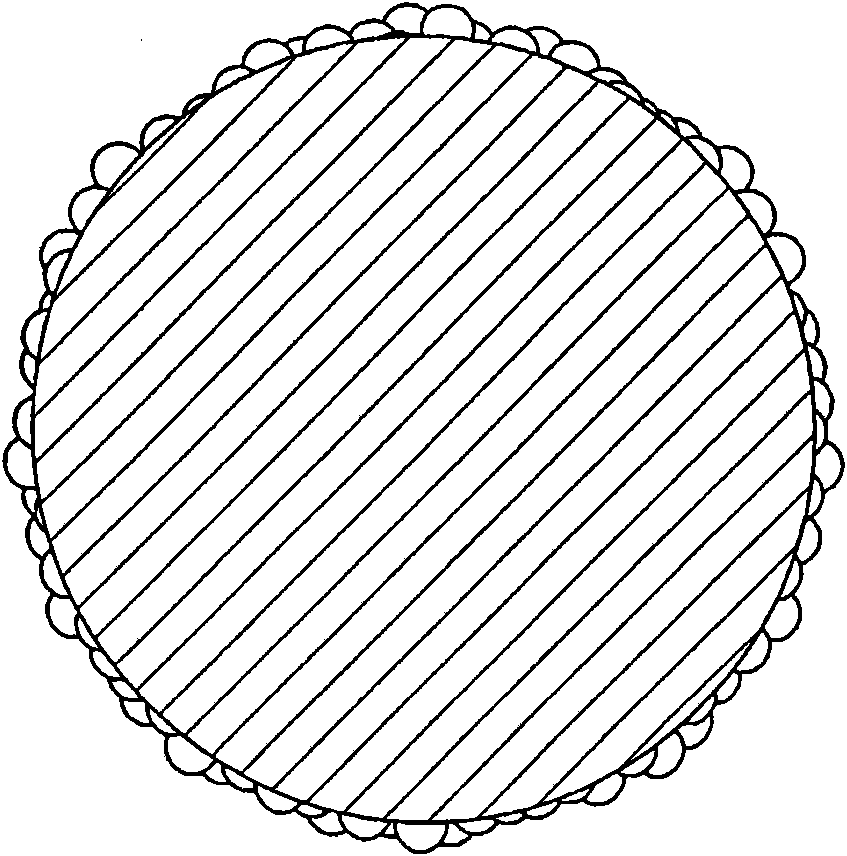

[0034] see Figures 1 to 3 , the preparation method of nanometer far-infrared cloth of the present invention comprises the following steps:

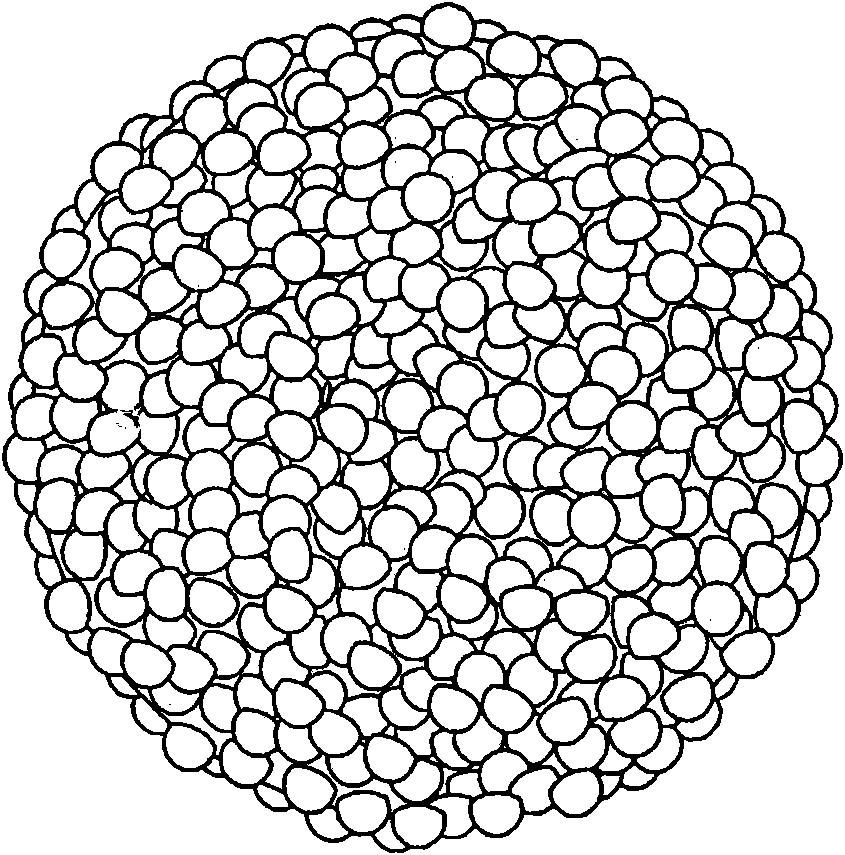

[0035] One, making nanoscale far-infrared polyurethane resin powder 11: the step of making nanoscale far-infrared polyurethane resin powder 11 is to make vanadium trioxide (V 2 o 3 ), yttrium oxide (Y 2 o 3 ), cuprous oxide (Cu 2 O), ferric oxide (Fe 2 o 3 ), aluminum oxide (Al 2 o 3 ), nickel oxide (NiO), silicon dioxide (SiO 2 ), magnesium oxide (MgO) and antimony oxide (Sb 2 o 3 ) of oxygen-containing compounds are mixed in a ratio of 1 to 1, the mixed material is vaporized at a high temperature above 1600°C, and the above-mentioned gasified products are collected by a dust collector to obtain a particle size of 100nm (100 nanometers (nm) equal to 0.1 micron (μm) below the comprehensive ultra-fine powder, and then with the particle size of up to 2000 mesh (mesh) macromolecular polyurethane resin powder (polyurethane resin p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com