Super-thick high-level boat plate steel and production process thereof

A production process and high-level technology, applied in the direction of process efficiency improvement, manufacturing converters, temperature control, etc., to achieve stable product performance, small quality fluctuations, and high product strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The chemical composition (mass percentage) of the E grade extra thick ship plate steel of the present embodiment is: C0.115%, Mn 1.14%, P0.007%, S0.0015%, Si 0.31%, Ni 0.18%, Cr0.06 %, Cu0.04%, Alt0.034%, Nb 0.025%, and the rest is Fe content. Cut a test block with a size of 200mmX100mmX60mm from a 60mm thick steel plate, and normalize a part of the test block at 880°C, 910°C and 940°C for 60 minutes; 100min, 120min normalizing treatment.

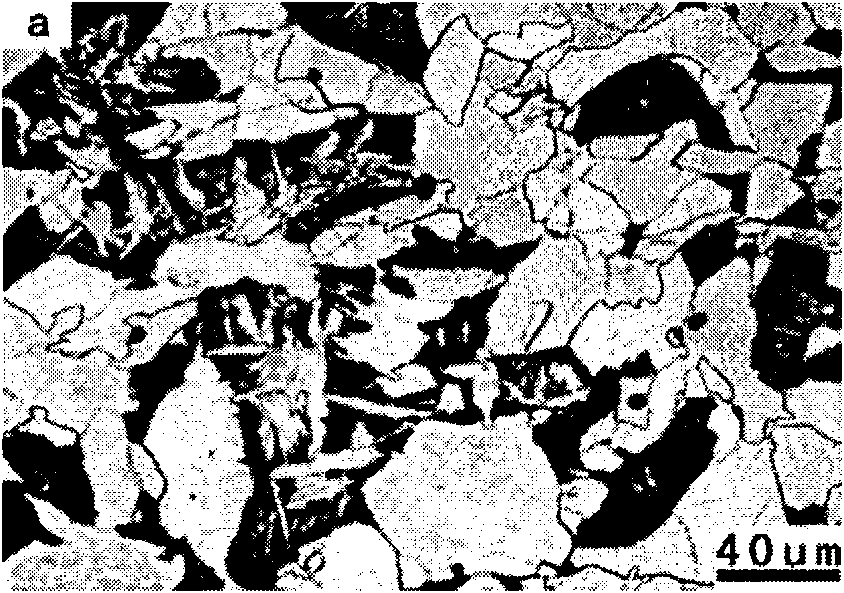

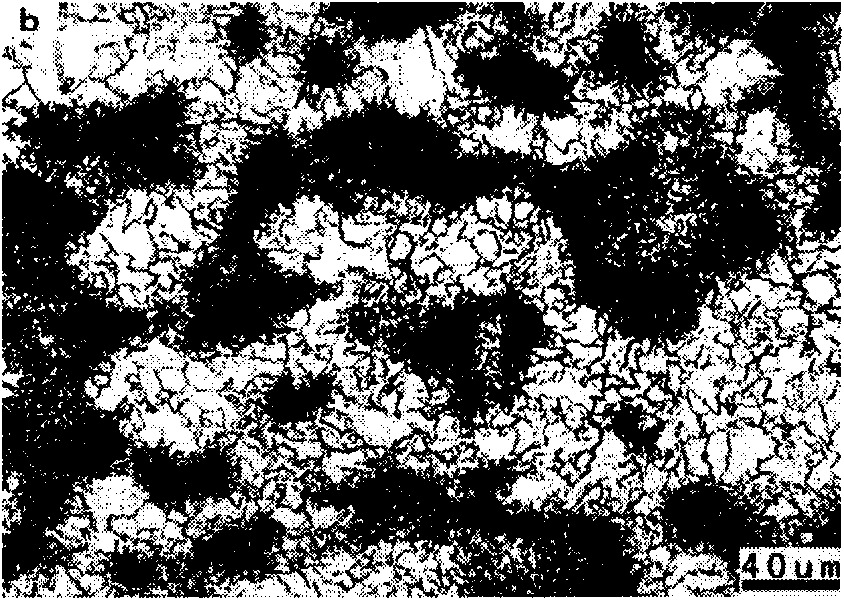

[0030] After normalizing, two impact samples and two tensile samples were wire-cut from 1 / 4 of the thickness direction of each test block, and then wire-cut from 1 / 2 (core) of each test block thickness direction. 2 impact specimens. The metallographic sample was taken out by wire cutting from the same part of the sample after impact. Grinding, polishing and corrosion of metallographic samples. The etchant was 4% nital, and the microstructure was observed with an optical microscope. figure 1 It is the original organizational char...

Embodiment 2

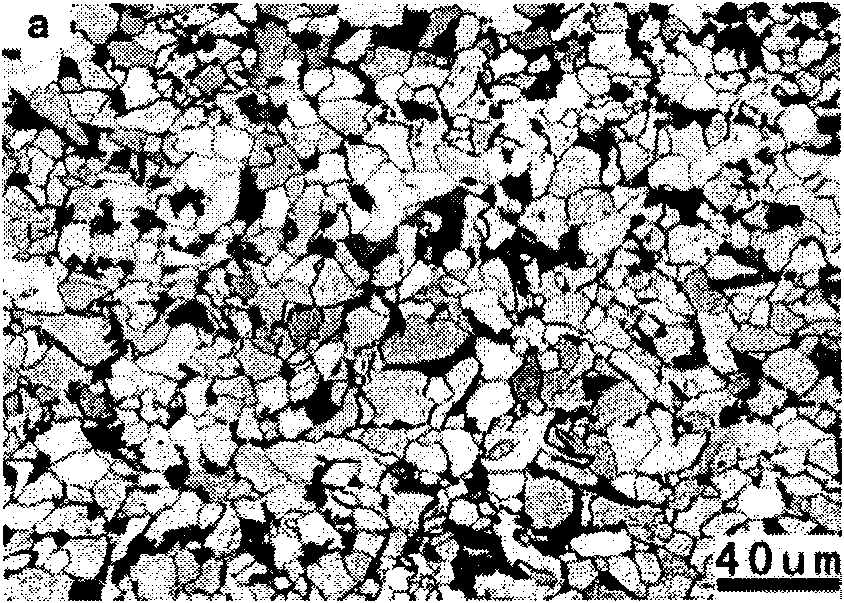

[0041] The chemical composition (mass percentage) of the E36 grade extra-thick ship plate steel in this example is: C0.113%, Mn 1.48%, P0.008%, S0.0019%, Si 0.31%, Ni 0.23%, Cr0.07% , Cu0.23%, Alt0.038%, Nb 0.028%, V0.044%, and the rest is Fe content. Cut a test block with a size of 200mmX100mmX60mm from a 60mm thick steel plate, and normalize a part of the test block at 880°C, 910°C and 940°C for 60 minutes; 100min, 120min normalizing treatment. Grinding, polishing and corrosion of metallographic samples. The etchant was 4% nital, and the microstructure was observed with an optical microscope. The tensile test was carried out on a CMT5305 precision microcomputer-controlled universal testing machine, and the yield strength, tensile strength and elongation of the sample were measured. The impact toughness of the material was tested by a pendulum impact testing machine. Figure 13 It is the original organizational chart of E36 extra thick and high ship plate steel. Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com