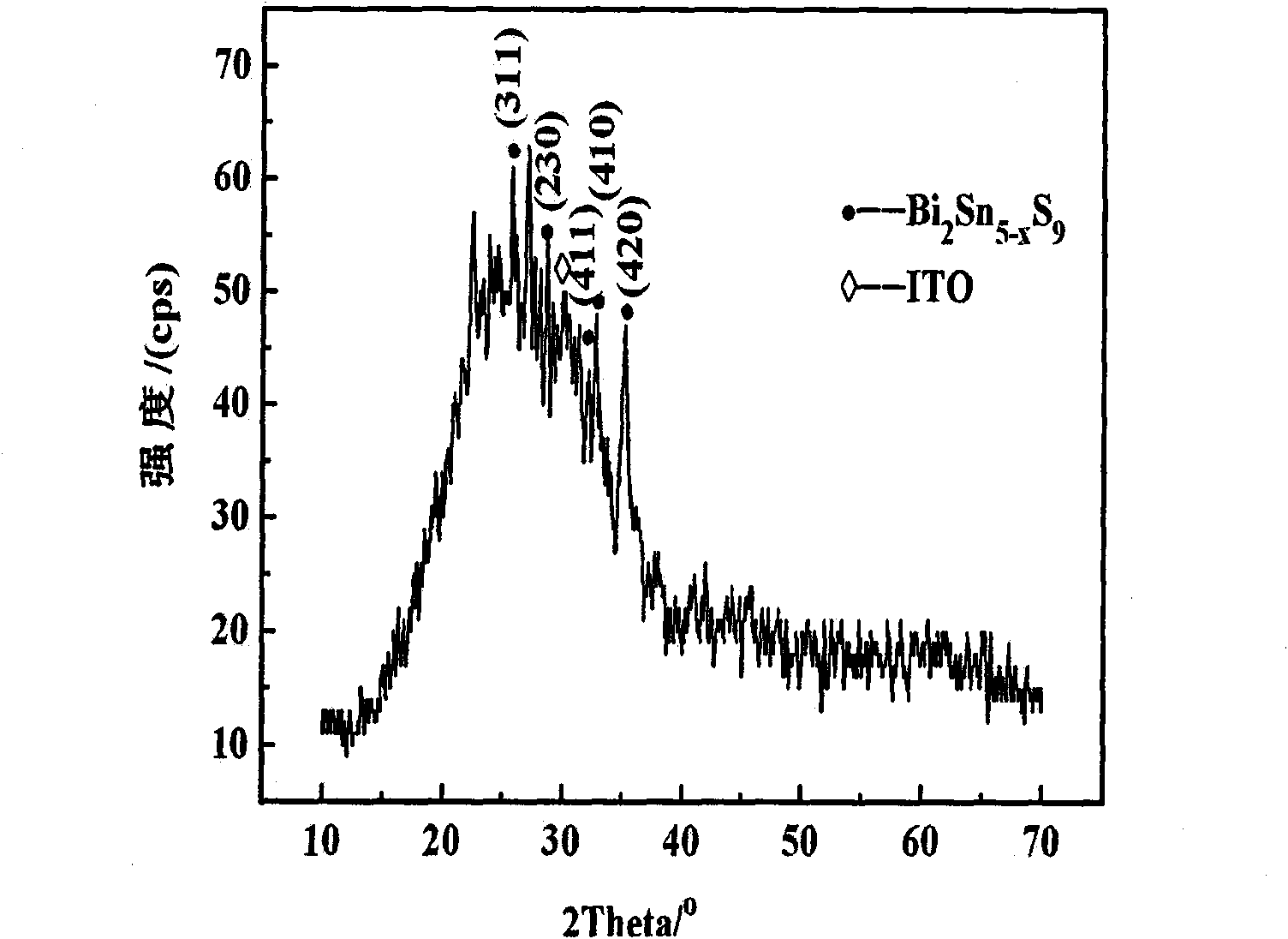

Method for preparing Sn doped Bi2S3 optical film

An optical thin film, 3·5H2O technology, applied in chemical instruments and methods, crystal growth, electrical components, etc., can solve problems such as unreported thin films, and achieve the effects of low cost, easy operation and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

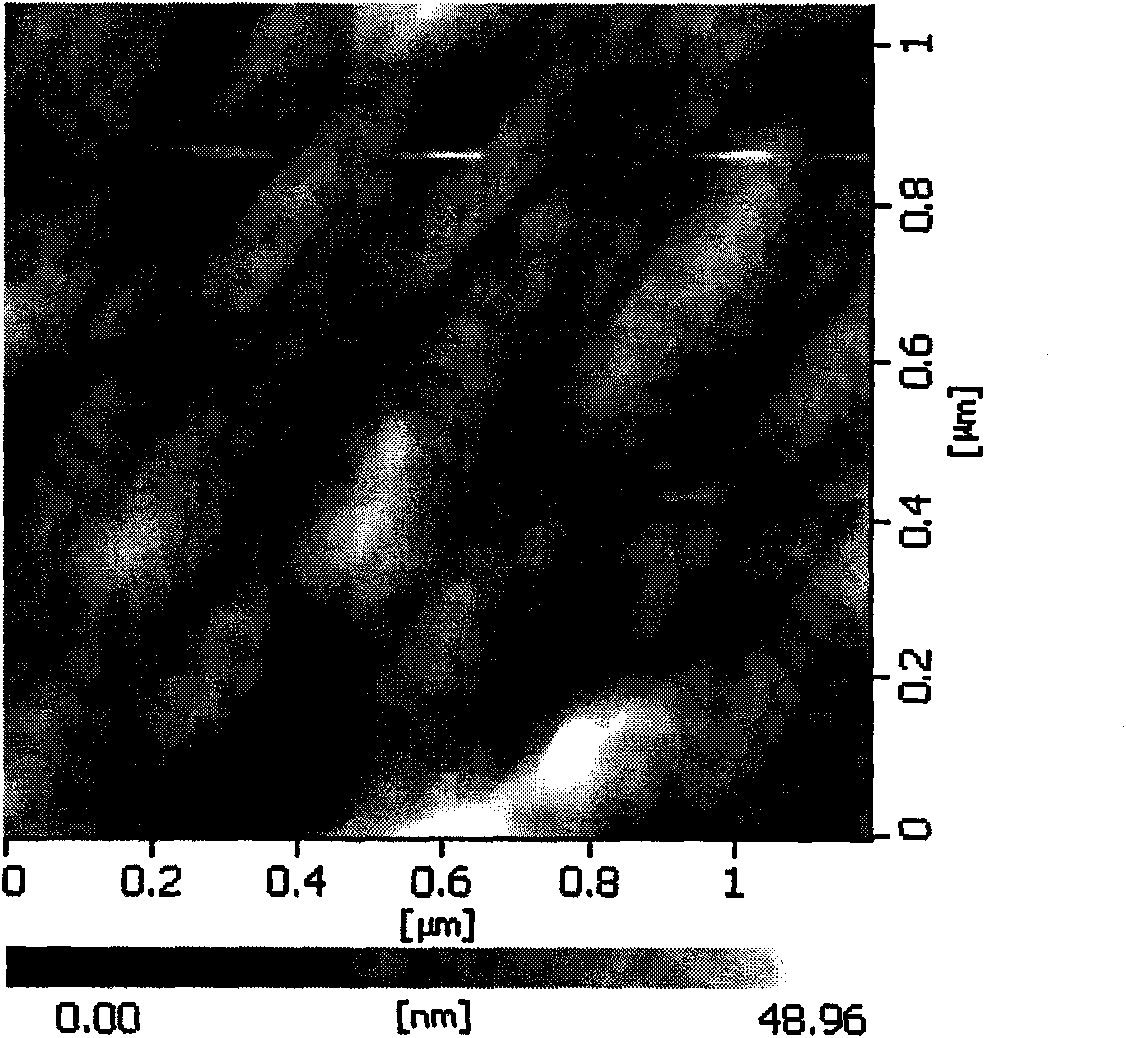

[0015] Embodiment 1: at first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator to ultrasonically disperse it to prepare Bi 3+ Concentration is the transparent solution of 0.0125mol / L, and the gained solution is recorded as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]: [S 2 o 3 2- ]: [C 6 h 5 o 7 3- ]=1:5:1 molar ratio, adjust the pH value to be 4.5 under stirring, and the gained solution is denoted as B; Analytical pure SnCl 2 2H 2 O is added to distilled water to configure Sn 2+ A transparent solution with an ion concentration of 1.25mmol / L, the resulting solution is denoted as C; add a 1% volume fraction of the C solution of the B solution to the B solution to form a precursor solution, and the resulting solution is denoted as D; the D solution is placed in the electrodeposition In the device, the ITO glass substrate was ultrasonicall...

Embodiment 2

[0017] Embodiment 2: at first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator to ultrasonically disperse it to prepare Bi 3+ Concentration is the transparent solution of 0.02mol / L, and the gained solution is recorded as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]: [S 2 o 3 2- ]: [C 6 h 5 o 7 3- ]=1: 6: 1 molar ratio, adjust the pH value to be 5.5 under stirring, and the gained solution is denoted as B; Analytical pure SnCl 2 2H 2 O is added to distilled water to configure Sn 2+ A transparent solution with an ion concentration of 1.25mmol / L, the resulting solution is denoted as C; add 0.2% volume fraction of the C solution of the B solution to the B solution to form a precursor solution, and the resulting solution is denoted as D; the D solution is placed in the electrodeposition In the device, the ITO glass substrate was ultrasonicall...

Embodiment 3

[0018] Embodiment 3: first will analyze pure Bi(NO 3 ) 3 ·5H 2 O was added to distilled water, and placed in an ultrasonic generator to ultrasonically disperse it to prepare Bi 3+ Concentration is the transparent solution of 0.03mol / L, and the gained solution is marked as A; Then, add analytically pure Na in A solution 2 S 2 o 3 and trisodium citrate, making the mixed solution [Bi 3+ ]: [S 2 o 3 2- ]: [C 6 h 5 o 7 3- ]=1: 7: 1 molar ratio, adjust the pH value to be 6.5 under stirring, and the gained solution is denoted as B; Analytical pure SnCl 2 2H 2 O is added to distilled water to configure Sn 2+A transparent solution with an ion concentration of 1.25mmol / L, the resulting solution is denoted as C; add a 0.8% volume fraction of the C solution of the B solution to the B solution to form a precursor solution, and the resulting solution is denoted as D; the D solution is placed in the electrodeposition In the device, the ITO glass substrate was ultrasonically cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com